Infrared temperature measuring device and heat treatment equipment

An infrared temperature measurement and infrared imager technology, which is used in measurement devices, optical radiation measurement, electrical radiation detectors, etc. The effect of high temperature measurement efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

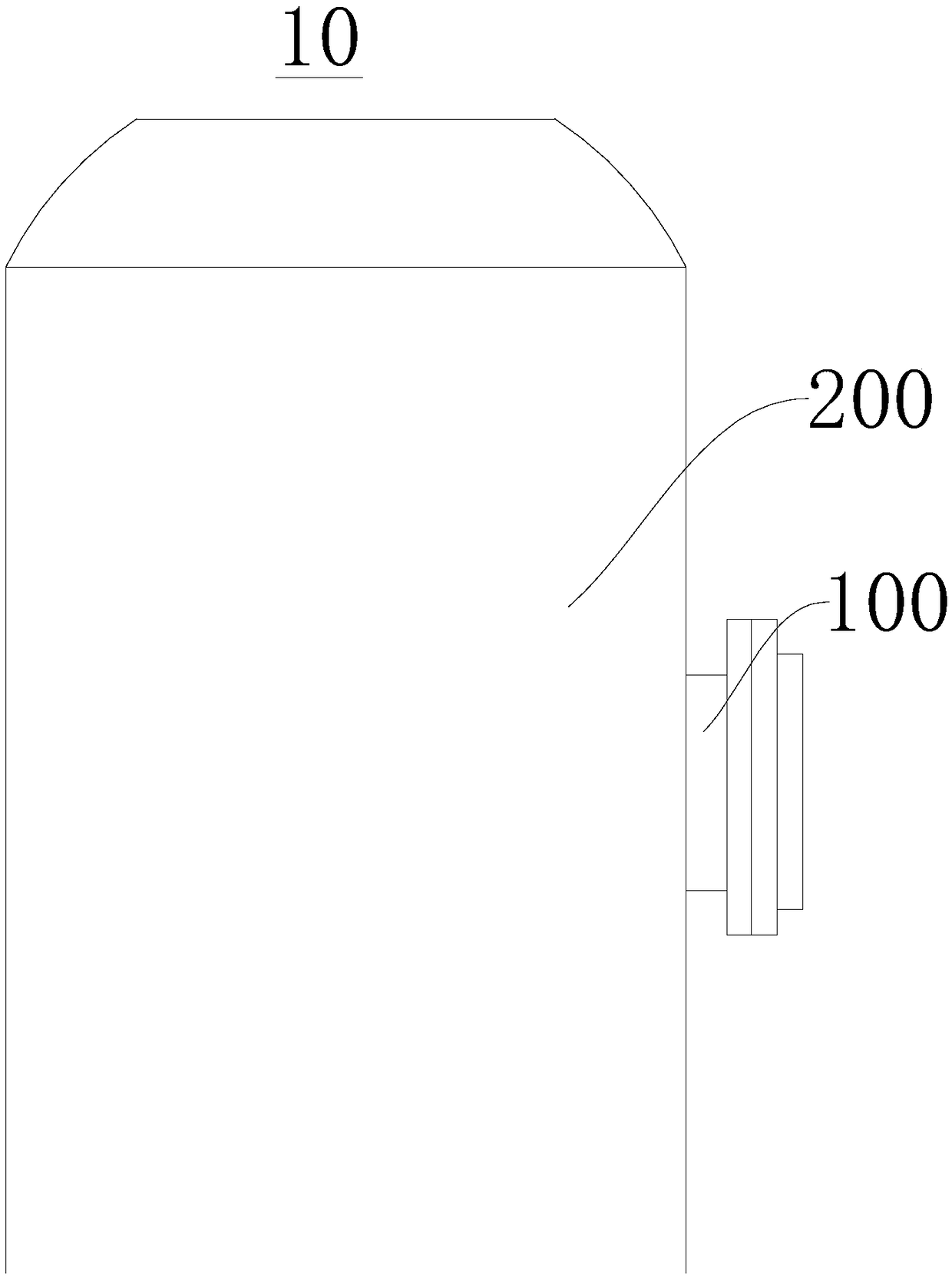

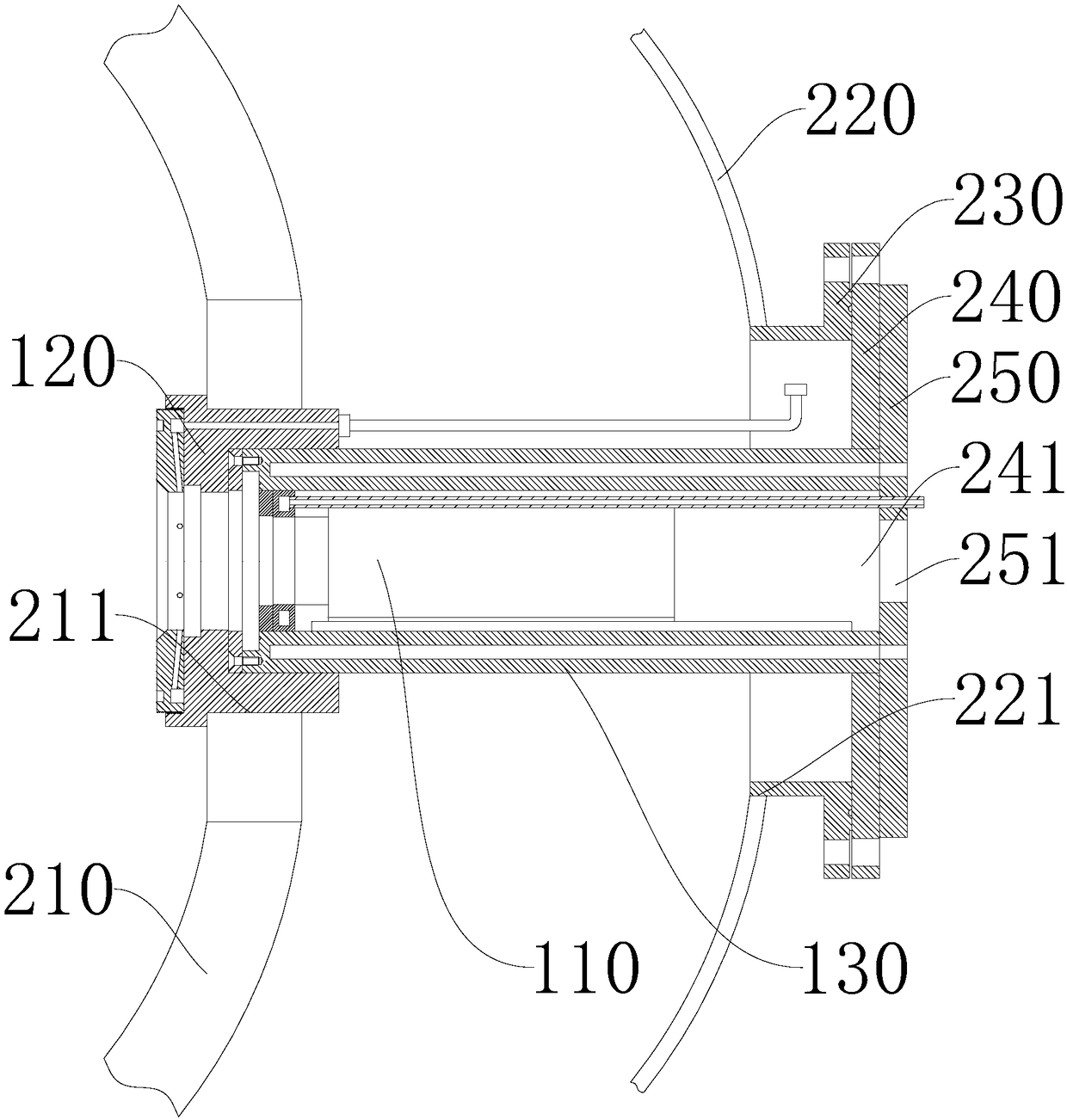

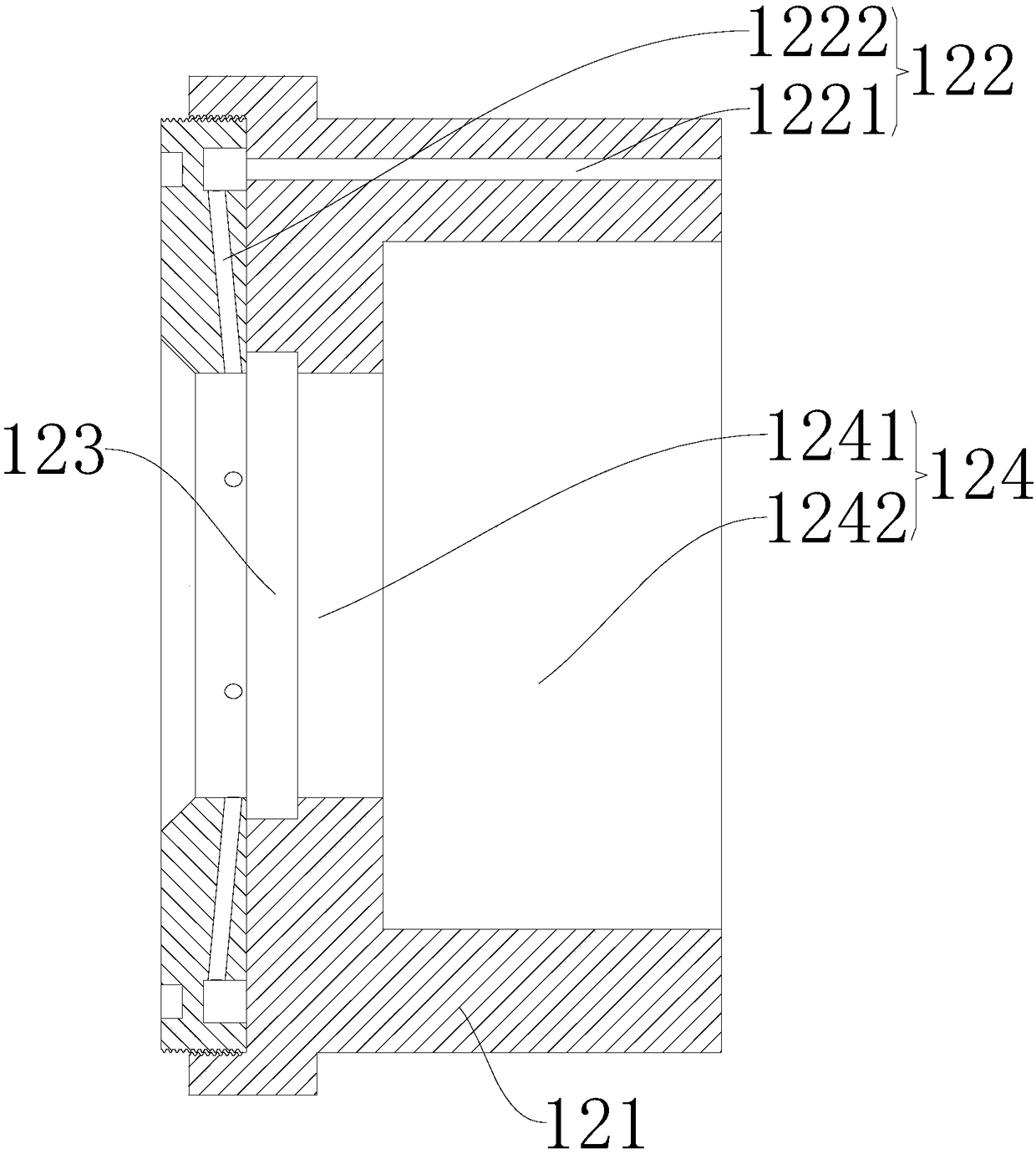

[0038] Please refer to figure 1 , the embodiment of the present invention provides a heat treatment device 10 for heat treatment of workpieces. The infrared temperature measuring device 100 inside has a simple structure and can ensure the normal operation of the infrared imaging mechanism to measure the temperature of the entire surface of the workpiece. The temperature measurement efficiency is high, the temperature measurement data is accurate, the practicability is strong, and the cost performance is high. The heat treatment equipment 10 includes a vacuum furnace 200 and an infrared temperature measuring device 100 . The infrared temperature measuring device 100 is installed on the vacuum furnace 200, the infrared temperature measuring device 100 is used to detect the temperature of the workpiece, and the vacuum furnace 200 is used to control the heating rate or cooling rate of the workpiece according to the detected temperature, so as to improve the quality of the workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com