A preparation method of fly ash-alumina double-layer composite microfiltration membrane

A double-layer composite, fly ash technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of wide average pore size distribution, low separation accuracy, difficult microfiltration membranes, etc. The effect of separation accuracy and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

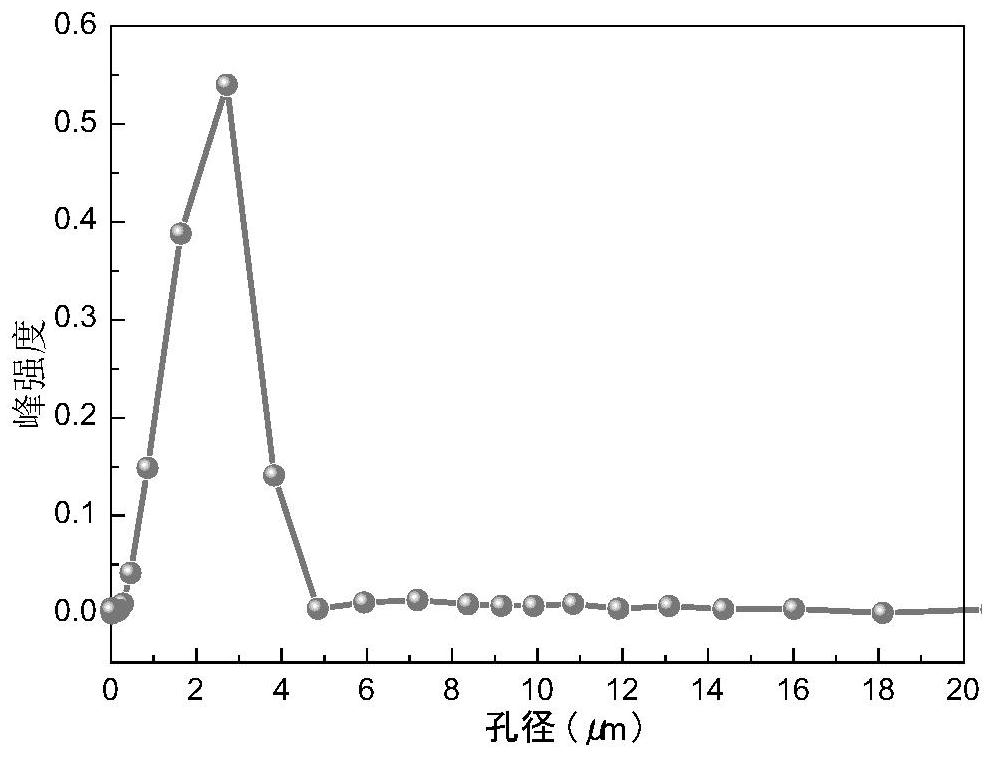

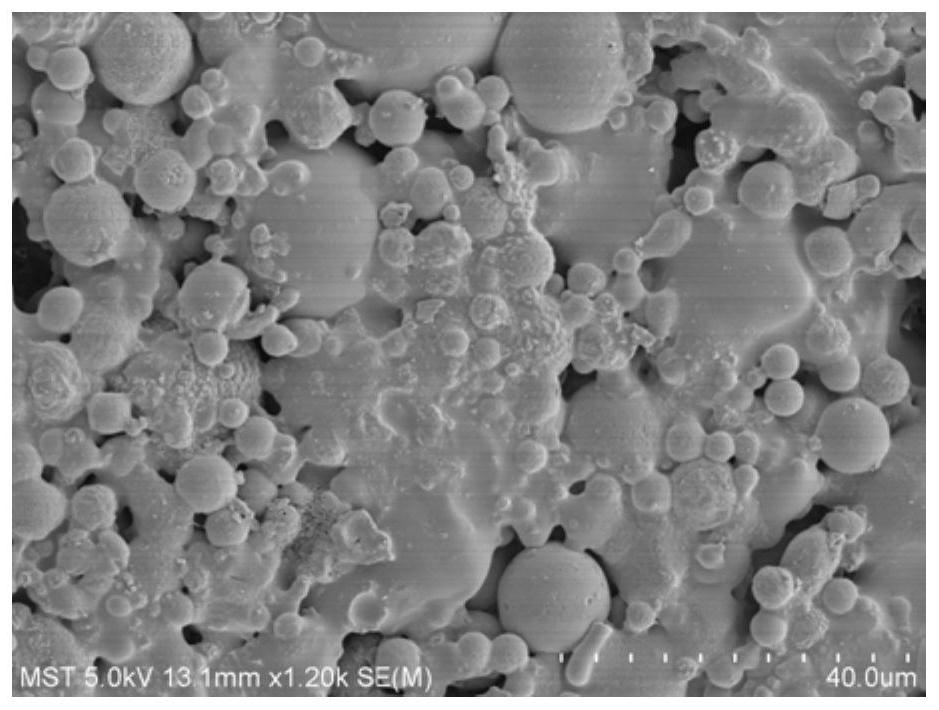

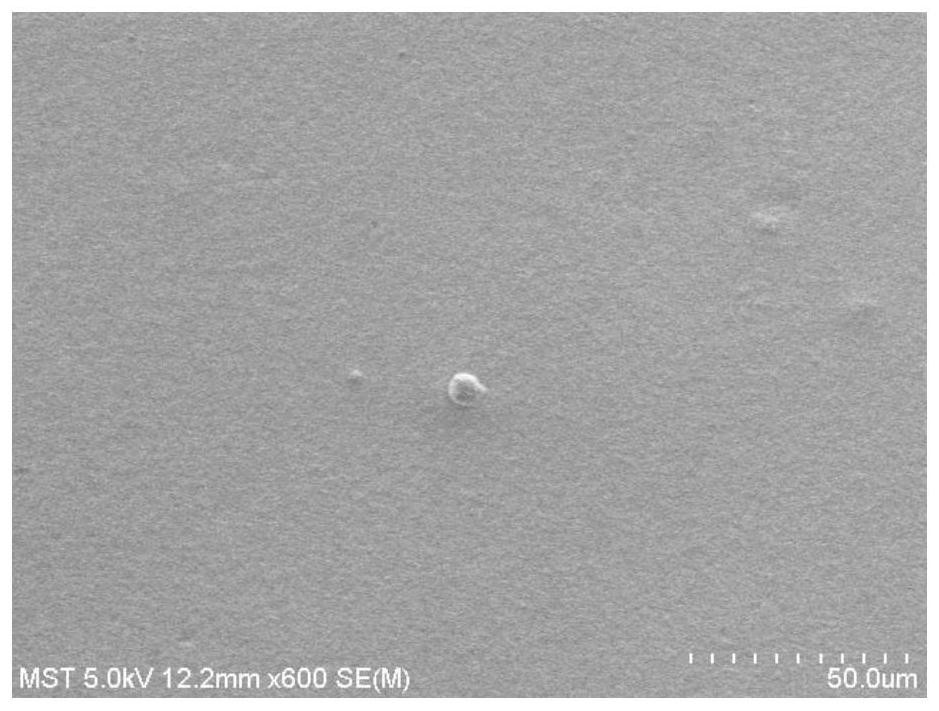

[0023] First, 100-mesh sieves were used to classify the fly ash. Glycerin is added to the classified powder for mixing and mud refining, wherein the added mass of glycerin accounts for 2% of the total mass of fly ash. The outer diameter of the tubular green carrier extruded by the extrusion molding machine is 12mm, and the inner diameter is 8mm. The heat treatment process of the ceramic green body is as follows: drying at a temperature of 70°C for 12 hours, sintering temperature at 1050°C, holding time for 5 hours, and heating and cooling rates at 2°C / min. The aluminum oxide powder with an average particle size of 300nm, a certain amount of sulfuric acid, and a certain amount of polyethylene glycol are prepared into a stable film-forming solution under the action of an ultrasonic instrument. The mass fraction of alumina in the prepared membrane-forming solution is 5wt.%, the mass fraction of the thickener is controlled at 20wt.%, and the pH value of the final prepared membran...

Embodiment 2

[0025] Firstly, the fly ash is classified by using a 1000-mesh sieve. Add polyvinyl alcohol to the classified powder for mixing and mud refining, wherein the added mass of polyvinyl alcohol accounts for 10% of the total mass of fly ash. The outer diameter of the tubular green carrier extruded by the extrusion molding machine is 16 mm, and the inner diameter is 10 mm. The heat treatment process of the ceramic green body is: drying at a temperature of 120°C for 36 hours, the sintering temperature at 1200°C, the holding time at 0.5h, and the heating and cooling rate at 5°C / min. The alumina powder with an average particle size of 1000nm, a certain amount of hydrochloric acid, and a certain amount of polyvinyl alcohol are prepared into a stable film-forming solution under the action of an ultrasonic instrument. The mass fraction of alumina in the prepared film-forming solution was 35wt.%, the mass fraction of the thickener was controlled at 5wt.%, and the pH value of the final pre...

Embodiment 3

[0027] First, 300-mesh sieves were used to classify the fly ash. Adding polyvinyl alcohol and glycerin to the classified powder for mixing and smelting, wherein the addition of glycerin and polyvinyl alcohol accounts for 4% of the fly ash mass. The outer diameter of the tubular green carrier extruded by the extrusion molding machine is 12mm, and the inner diameter is 8mm. The heat treatment process of the ceramic green body is: drying at a temperature of 110°C for 24 hours, the sintering temperature at 1100°C, the holding time at 2 hours, and the heating and cooling rate at 3°C / min. The aluminum oxide powder with an average particle size of 300nm, a certain amount of nitric acid, and a certain amount of methyl cellulose are prepared into a stable film-forming solution under the action of an ultrasonic instrument. The mass fraction of alumina in the prepared membrane-forming solution is 25wt.%, the mass fraction of the thickener is controlled at 15wt.%, and the pH value of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com