Condensate treater

A condensate and processor technology, applied in the field of condensate processors, can solve the problems of environmental pollution and high processing costs, and achieve the effects of reducing environmental pollution, improving separation accuracy, and reducing COD value and oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

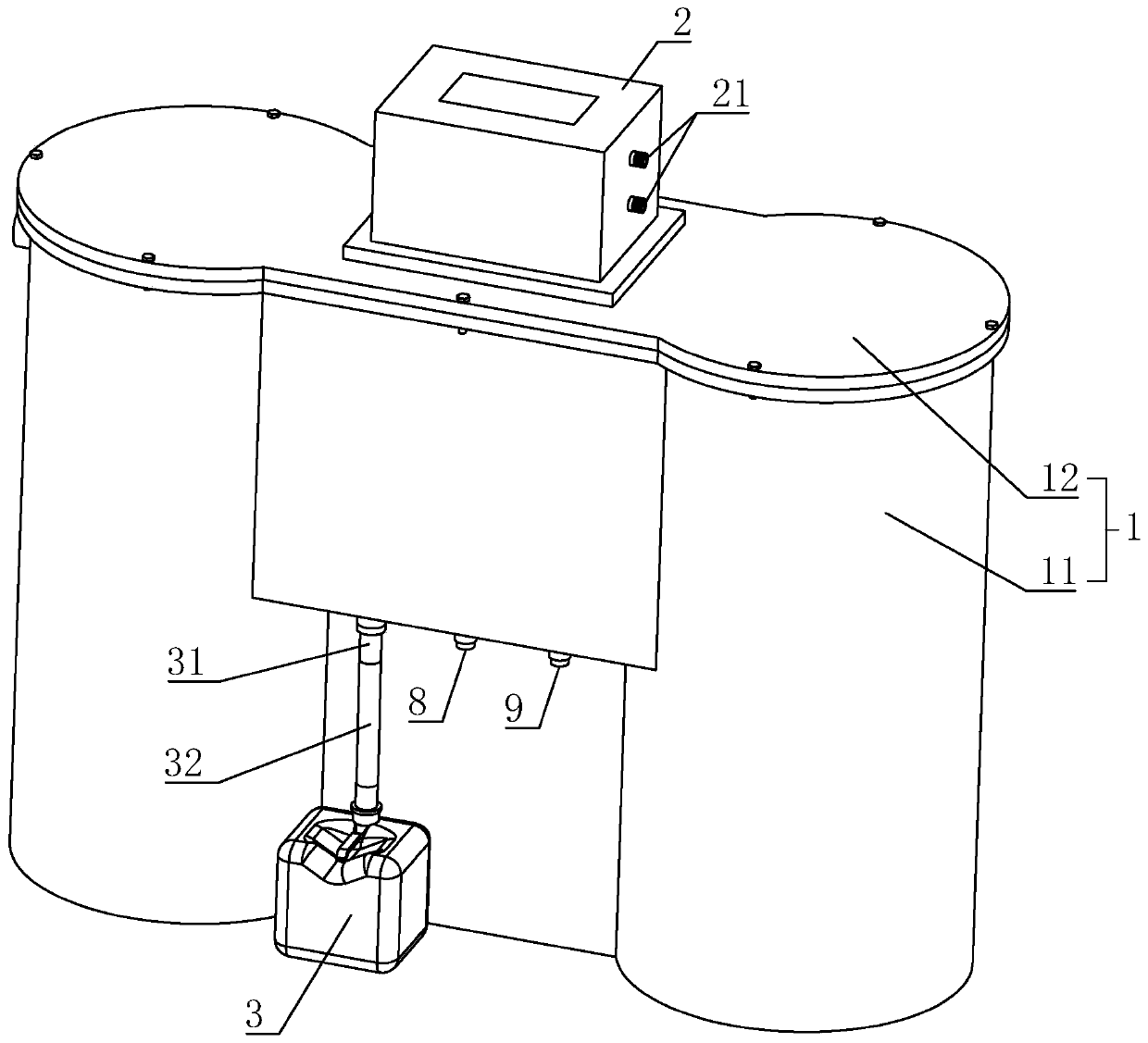

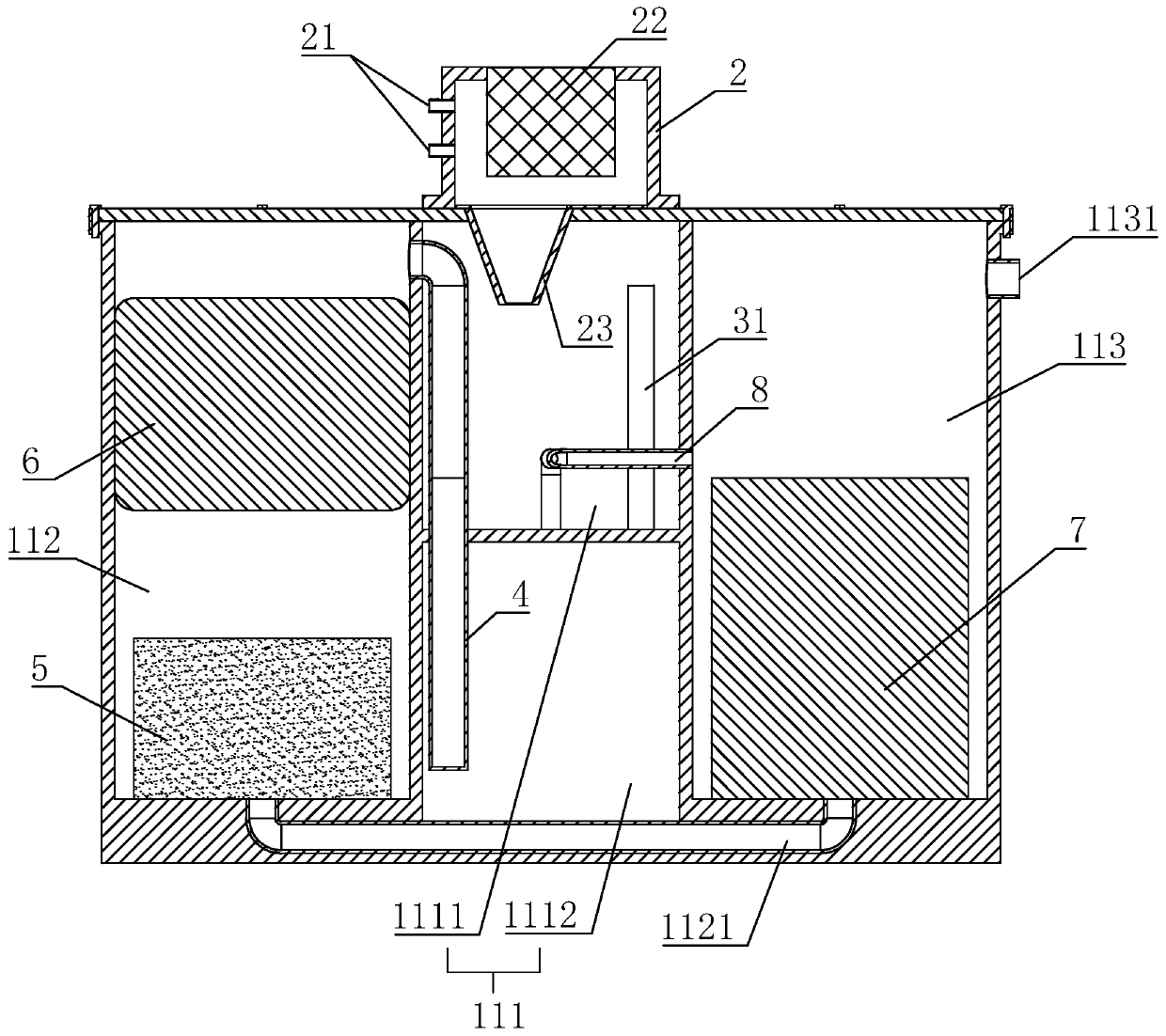

[0032] Embodiment: a kind of condensate processor, such as figure 1 with figure 2 , including a box body 1 and an oil storage barrel 3, the box body 1 includes a bottom box 11 and an upper cover 12, the upper cover 12 is detachably connected to the bottom box 11 by bolts and closes the top of the bottom box 11. The bottom box 11 is provided with a pre-separation warehouse 111, a primary filter warehouse 112 and a secondary filter warehouse 113, the secondary filter warehouse 113 and the primary filter warehouse 112 are respectively located on the left and right sides of the pre-separation warehouse 111, and the pre-separation warehouse 111 is set It is an inverted L shape consisting of an upper bin 1111 and a lower bin 1112, and the oil storage barrel 3 is placed under the upper bin 1111 so as to be located in the same cuboid as the primary filter bin 112 and the secondary filter bin 113 to reduce condensate treatment The space occupied by the device is reduced, and the poss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com