A waste oil pretreatment system

A waste oil and pretreatment technology, which is applied in the fields of fat oil/fat refining, fat oil/fatty acid recovery from waste materials, and fatty substance recovery, etc. It can solve the problems that waste oil and hot water cannot be fully mixed, soluble salt cannot be fully removed, noise and Large power consumption and other issues, to achieve oil-water separation accuracy and good separation effect, compact structure, high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

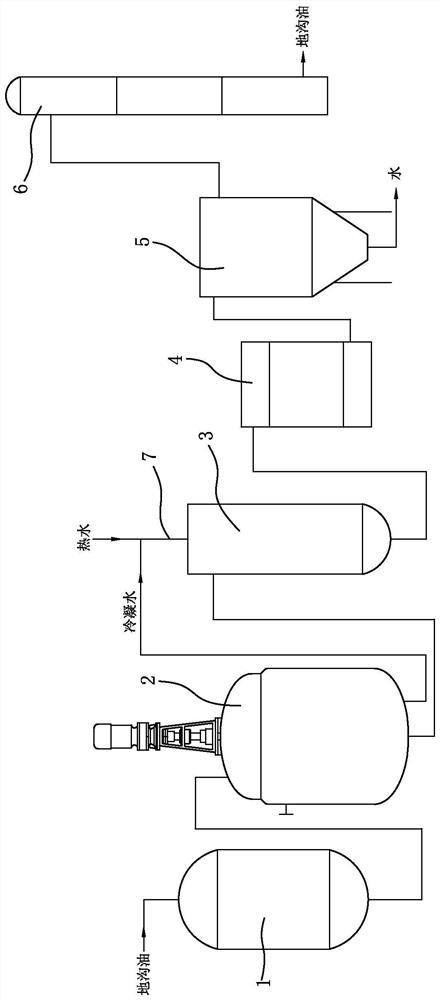

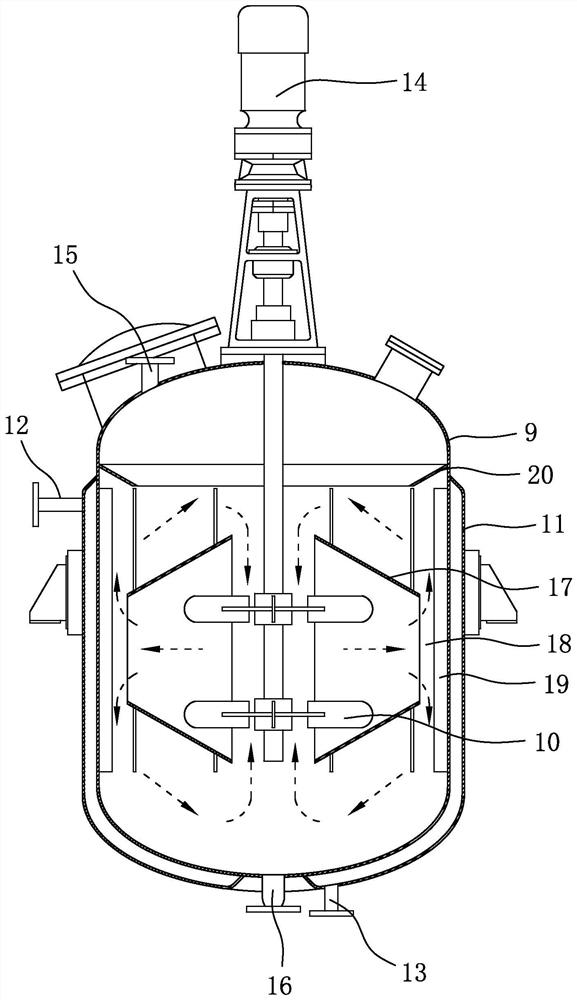

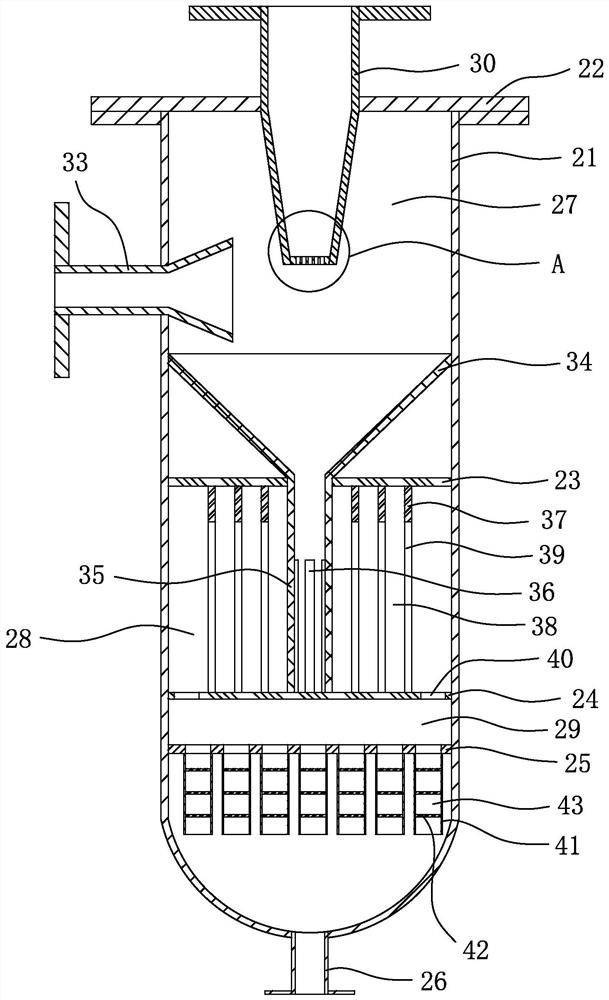

[0033] like figure 1 The shown kind of waste oil pretreatment system includes waste oil storage tank 1, heating and stirring tank 2, oil-water mixer 3, ultrasonic demulsification tank 4, oil-water separation device 5 and desulfurization tower 6, and the bottom of the waste oil storage tank is provided with The outlet of the gutter oil storage tank, the inlet of the heating and stirring tank is arranged on the top of the heating and stirring tank, and the outlet of the gutter oil storage tank is connected with the inlet of the heating and stirring tank through a pipeline; the bottom of the heating and stirring tank is provided with the outlet of the heating and stirring tank, and the upper part of the oil-water mixer is provided with oil and water The inlet of the mixer, the top of the oil-water mixer is provided with a hot water inlet, the hot wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com