Feed grinding device for animal husbandry

A grinding device and animal husbandry technology, applied in the field of animal husbandry machinery, can solve the problems of insufficient refinement of feed and poor grinding effect, and achieve the effects of improving feed grinding efficiency, ingenious structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

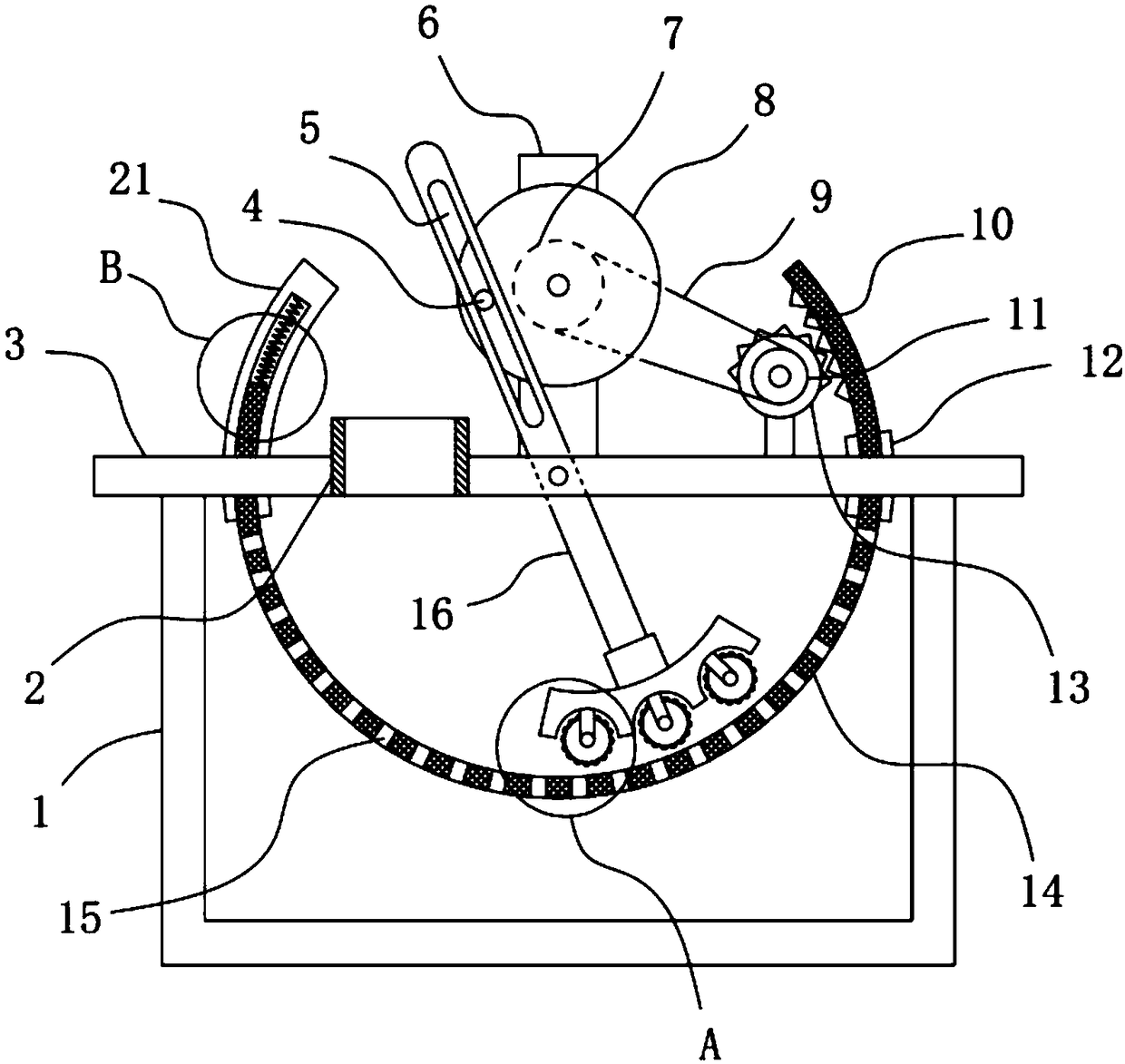

[0023] see Figure 1-2 , a feed grinding device for animal husbandry, comprising a collection box 1, a horizontal plate 3 is fixedly installed horizontally on the collection box 1, a support frame 6 is vertically fixedly installed on the horizontal plate 3, and a rotating type is installed on the support frame 6. The rotating disc 8 can be driven and rotated with an external drive motor, and the output shaft of the driving motor is coaxially fixed with the rotating disc 8 .

[0024] The front of the rotating disk 8 is coaxially fixed with a rotating disk 8, and the front of the rotating disk 8 is eccentrically fixed with a transmission pin 4. The horizontal plate 3 is rotatably provided with a rotating plate 16, and the rotating plate 16 is provided with a guide bar hole 5. The transmission pin shaft 4 slides through the guide bar hole 5 , and the transmission pin shaft 4 can slide along the guide bar hole 5 to realize the transmission effect on the rotating plate 16 .

[002...

Embodiment 2

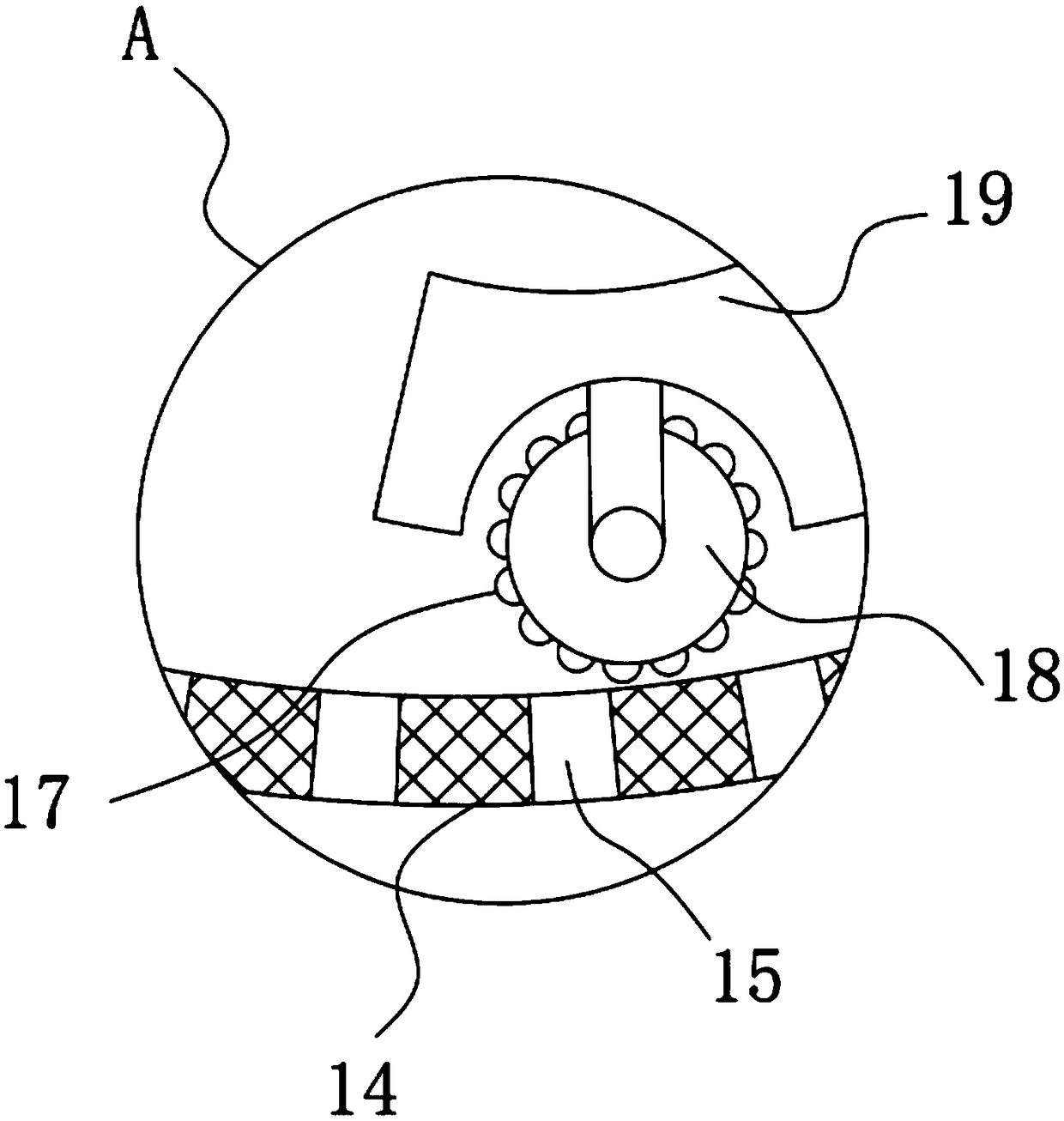

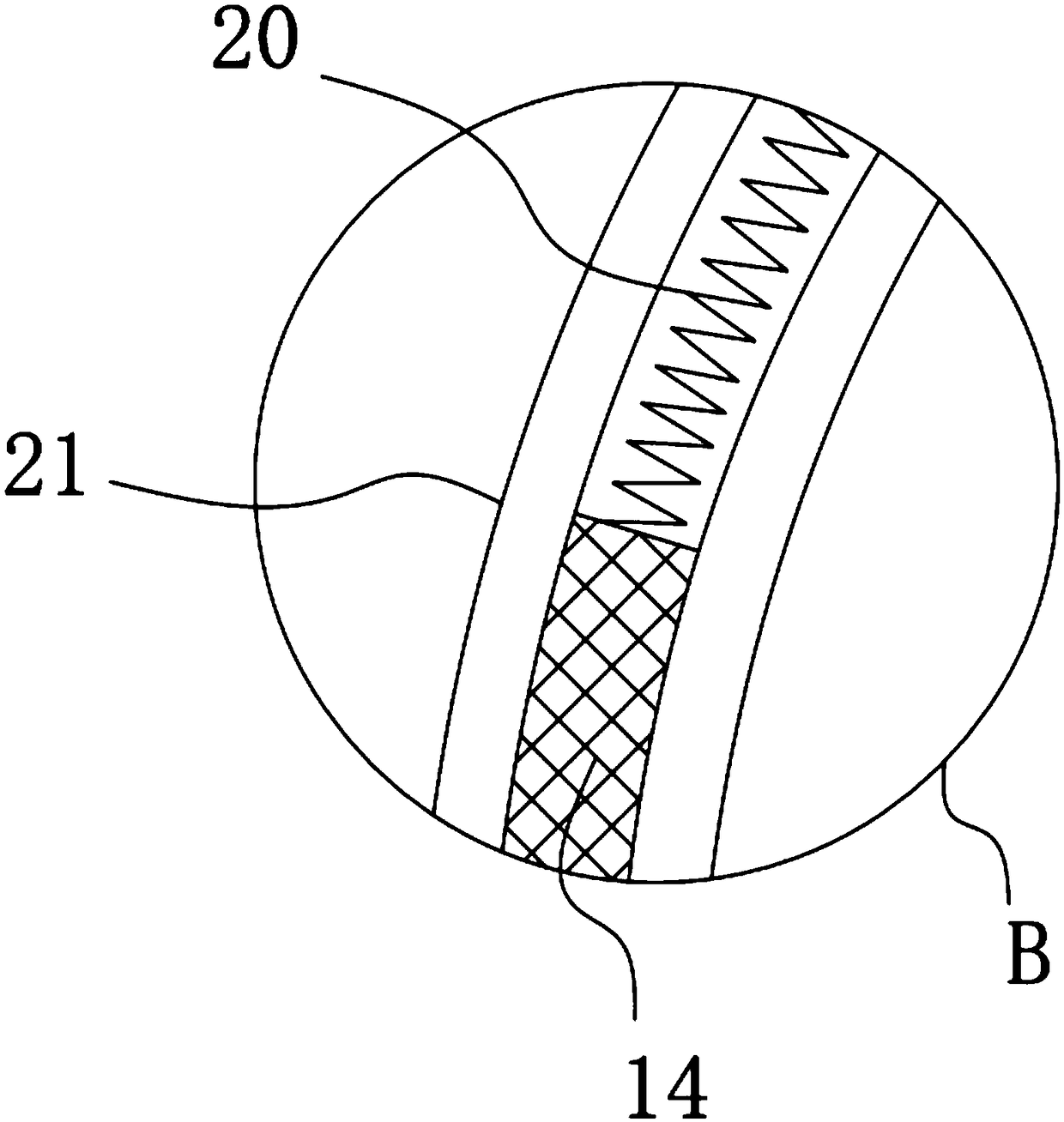

[0028] On the basis of Embodiment 1, in addition, the limit cover plate 21 and the limit arc plate 12 are fixedly installed on the horizontal plate 3, and the left end of the arc plate 14 is slidably embedded in the limit cover plate 21, and the arc plate 14 Sliding through the limiting arc plate 12, the inner rack 10 is fixedly installed on the inner wall of the inner rack 10, and the horizontal plate 3 is rotatably provided with an incomplete gear 13 that is in transmission engagement with the inner rack 10.

[0029] Further, the driving pulley 7 is coaxially fixedly installed on the back of the rotating disk 8, the driven pulley 11 is fixedly installed coaxially on the incomplete gear 13, and the driving belt 9 is sleeved on the driven pulley 11 and the driving pulley 7. .

[0030] The rotation of the rotating disk 8 drives the driving pulley 7 to rotate, and the driving pulley 7 drives the driven pulley 11 to rotate through the transmission belt 9, and the driven pulley 11...

Embodiment 3

[0033] On the basis of Example 2, such as Figure 4 As shown, in addition, the side wall hinge of the collection box 1 is connected with a dodge door 22, and the dodge door 22 is fixedly equipped with a connection ear 23, and the connection ear 23 is provided with a locking screw threaded with the collection box 1, and the feed grinding is completed. Finally, the dodge door 22 can be opened by removing the locking screw, and now the ground feed can be taken out from the collection box 1, and the operation process is simple and convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com