Pipe Fitting Gluing Equipment

A technology for pipe fittings and gluing, which is applied to coatings and devices for coating liquid on the surface, etc., can solve the problems of unfavorable saving of production costs, waste of materials, complicated procedures, etc., and achieve cost saving, pollution reduction, and reduction of irritating odor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

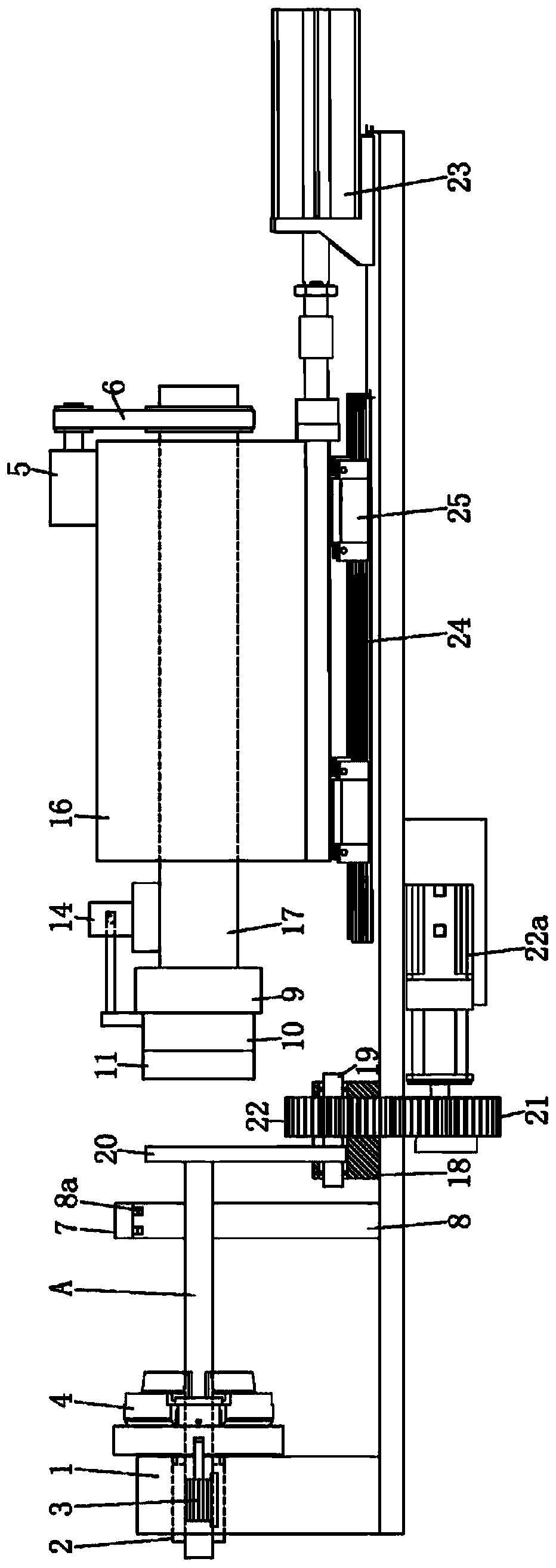

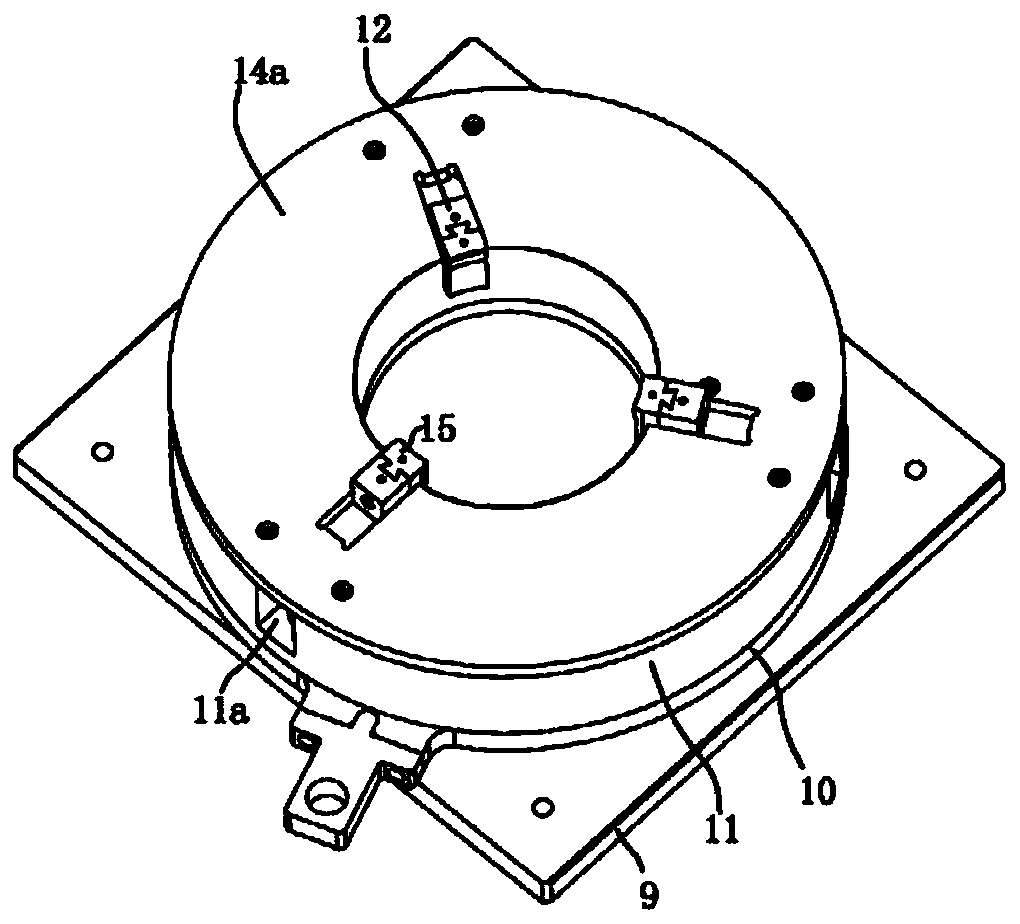

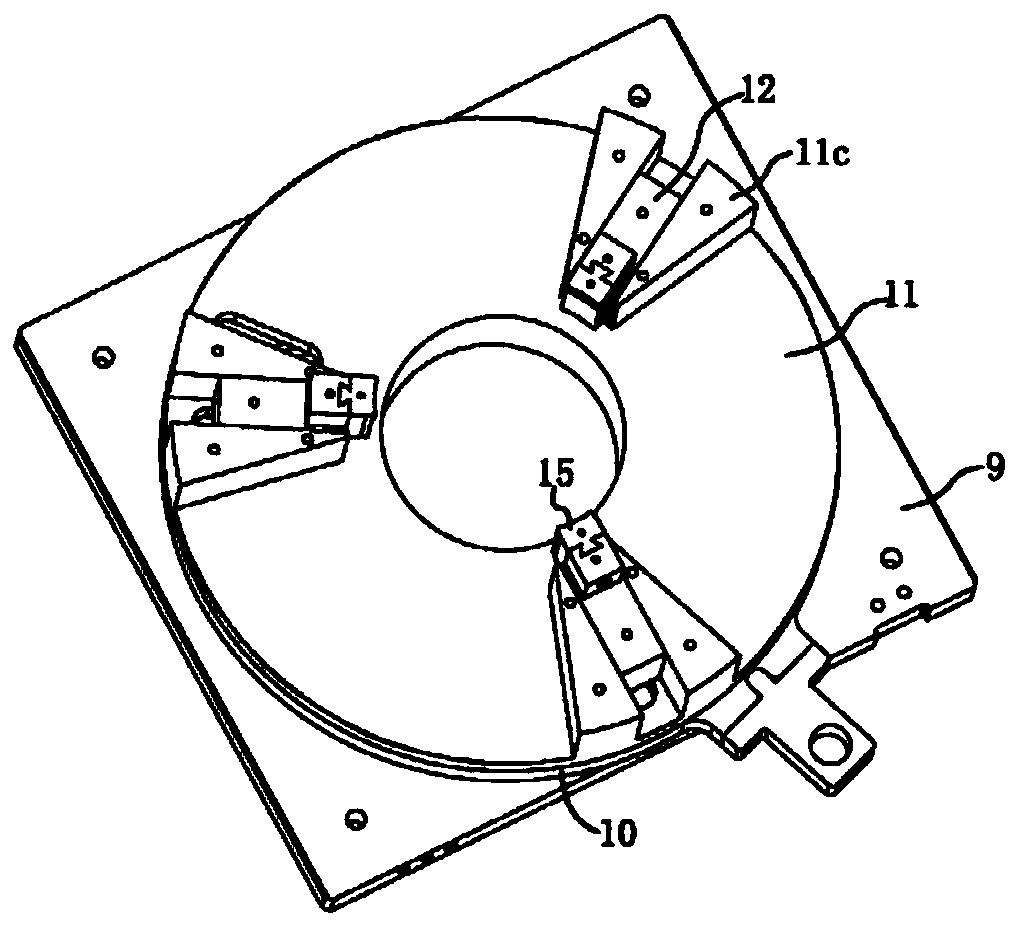

[0029] Such as figure 1 As shown, the pipe fitting gluing equipment of the present invention includes a support seat, a clamp, a first driving mechanism, a glue feeding mechanism, a gluing mechanism, a mounting seat, and a driving mechanism. Each part and the relationship between them will be described in detail below :

[0030] Such as figure 1 As shown, a first through hole is provided on the support base 1, and a guide sleeve 2 is installed in the first through hole. The function of 2 forms a supporting effect on one end of the pipe fitting A. The first through hole is a stepped hole, and one end of the guide sleeve 2 is limited by the step of the stepped hole, and the other end of the guide sleeve 2 is exposed outside the first through hole, so that when installing and dismounting the guide sleeve 2 It is very convenient, and through the position-limiting effect of the steps, when the pipe fitting A passes through the guide sleeve 2, the guide sleeve 2 will not move und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com