A track groove wall cleaning device

A cleaning device and track groove technology, applied in cleaning methods and appliances, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as inaccurate detection results and influence of detection results, and achieve wide application range and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

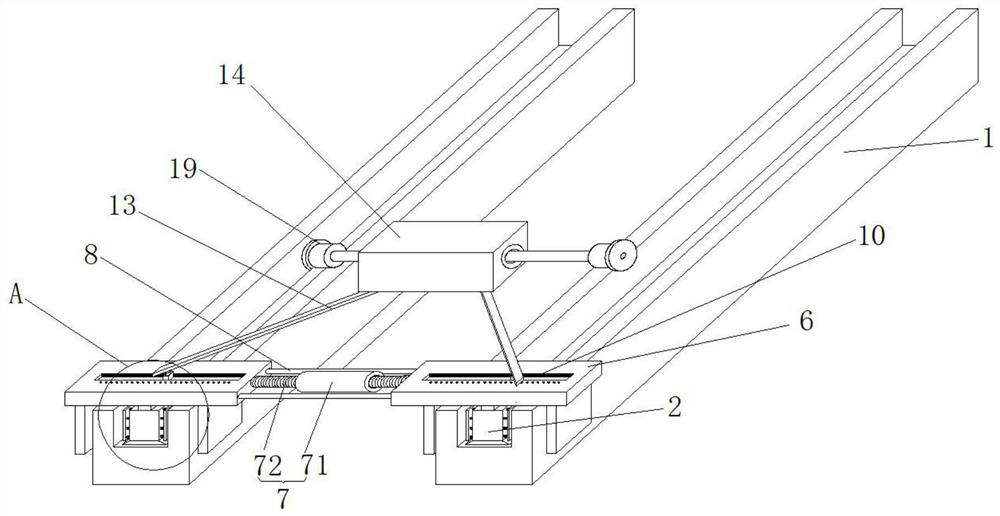

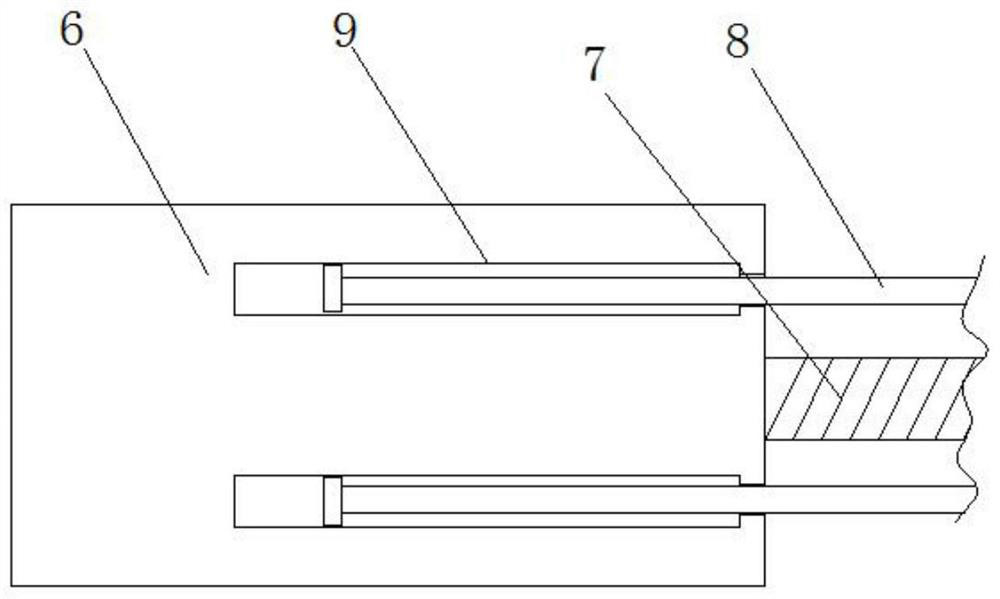

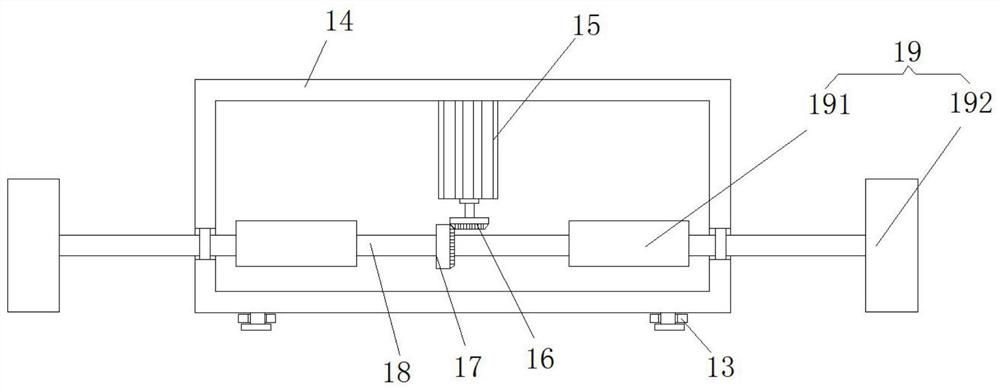

[0021] see Figure 1-4 , this embodiment provides a track groove wall cleaning device, including two track bodies 1, the inner walls of the two track bodies 1 are slidingly connected with brush blocks 2, and both sides of the brush block 2 are fixedly connected with springs 3. The end of the spring 3 away from the brush block 2 is fixedly connected to the brush plate 4, the bottom of the brush block 2 is fixedly connected to the scraper 5, and the tops of the two brush blocks 2 are fixedly connected to the mounting plate 6, and the two mounting plates 6 An adjustment assembly 7 is fixedly connected between the two mounting plates 6, and a limiting rod 8 is arranged between the two mounting plates 6. The opposite sides of the two mounting plates 6 are provided with a limiting groove 9, and the limiting rod 8 is movably connected with the limiting groove 9, and the limiting The position bar 8 is a T-shaped bar, and the top of the mounting plate 6 is provided with a convex groove...

Embodiment 2

[0024] see Figure 1-4 A further improvement is made on the basis of Example 1: the brush plate 4 is a plastic plate, and the side of the brush plate 4 away from the spring 3 is provided with a sponge, and the stain on the inner wall surface of the track body 1 can be effectively wiped by the sponge , and the cleaning effect is better, the adjustment assembly 7 includes a threaded sleeve 71, the two ends of the threaded sleeve 71 are threaded with a threaded rod 72, the threaded rod 72 is fixedly connected with the mounting plate 6, and the thread directions of the two threaded rods 72 are opposite , when cleaning different tracks, the threaded sleeve 71 can be rotated to cause relative displacement of the two threaded rods 72, thus playing the role of adjusting the distance between the two mounting plates 6, wherein the thread direction of the two threaded rods 72 is set In contrast, it is ensured that the movement paths of the two threaded rods 72 are always opposite, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com