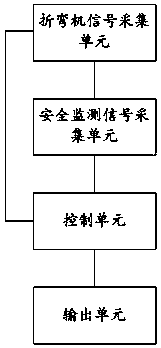

Safety protection method and system for bending machine

A technology for safety protection and bending machines, which is applied in the field of bending machines, can solve the problems of personal injury of operators, operator clamping, being pinched off, etc., to increase the safety detection range, increase the safety of use, and highlight the substantive characteristic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0039] The present invention provides a safety protection method for a bending machine, comprising the following steps s1-s5.

[0040] Step s1, collect the finished workpiece shape instruction issued by the target bending machine to process the finished workpiece to be processed.

[0041] It should be noted that the target bending machines involved in the safety protection method for bending machines in the present invention are all bending machines to which the safety protection method for bending machines is applied.

[0042] Step s2, based on the finished workpiece shape instruction for processing the finished workpiece to be processed by the target bending machine collected above, correspondingly obtain the preset processing sequence number corresponding to the above collected finished workpiece shape instruction and Each processing sequence number corresponds to the shape of the workpiece, and correspondingly forms a processing sequence set corresponding to the collected ...

specific Embodiment approach 2

[0068] This embodiment provides another safety protection method for a bending machine. Compared with Embodiment 1, the difference between this method is that the safety protection method for a bending machine described in this embodiment further includes a display step for Display the corresponding set of processing procedures formed, which is convenient for the user to visually view the progress of the current processing procedure, which is helpful to the smooth progress of the bending work to a certain extent.

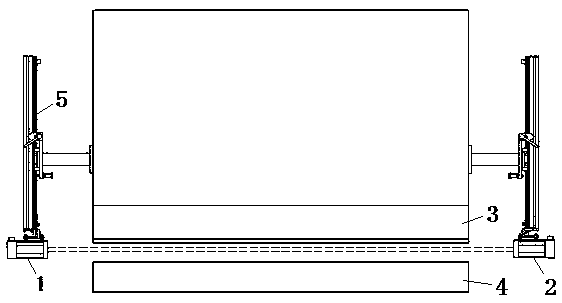

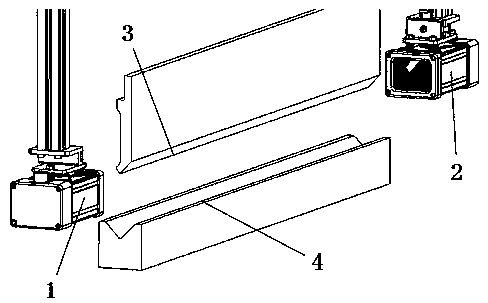

[0069] in addition, Figure 3-5 It is another specific embodiment of the safety protection system for the bending machine of the present invention. Compared with specific embodiment 1, the safety protection system for bending machine described in this embodiment also includes a display unit 6.1, which is connected to the control unit and is used to display the information formed by the control unit. Each corresponding processing procedure set. When in use, each co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com