Hardware polishing machine capable of preventing eye injury

A polishing machine and hardware technology, used in grinding/polishing equipment, grinding/polishing safety devices, grinding machines, etc., can solve problems such as not being able to prevent operator eye damage, improve heat dissipation, avoid The effect of the device falling off and improving the usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

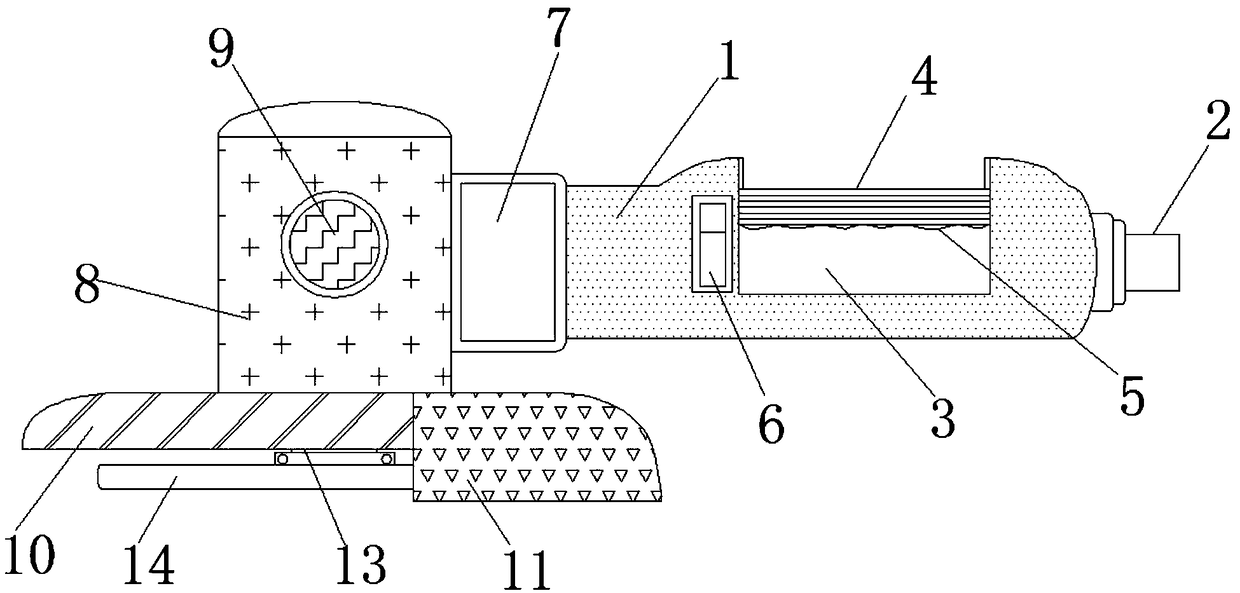

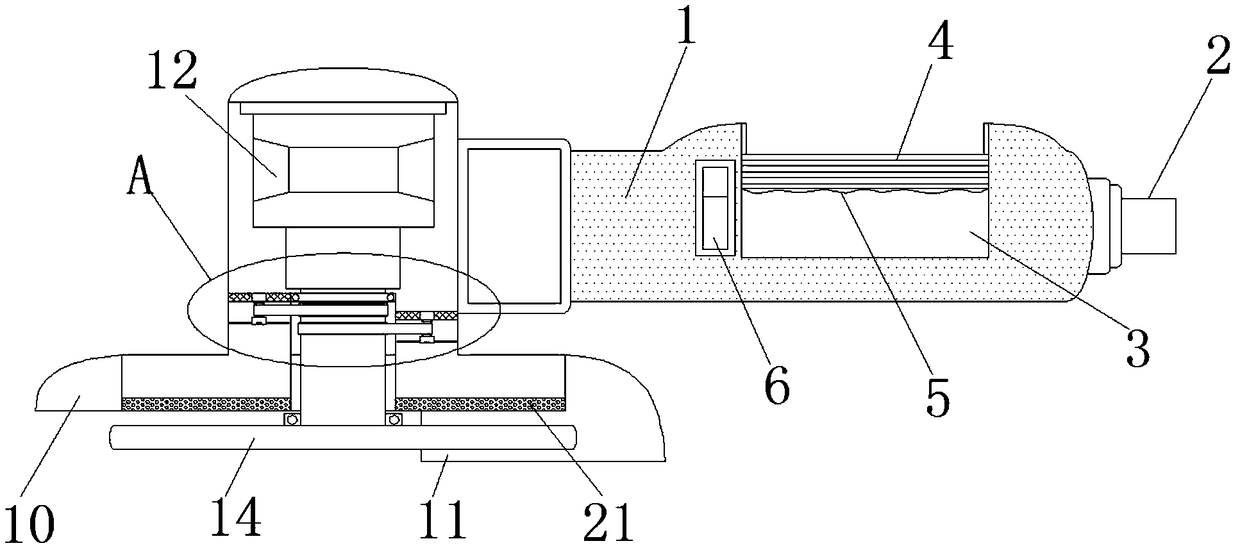

[0020] Example 1, such as figure 1 , 2 Or as shown in 3, first put your hand into the groove 3, and then hold the first anti-slip stripe grip 4, under the anti-slip effect of the first anti-slip stripe grip 4 and the rubber protrusion 5, the operator can move steadily Holding the device prevents the device from falling off during operation, causing accidental injury or causing damage to the device, thereby improving the practicability of the device.

[0021] The grip end 1 is provided with an operation button 6, the left side of the grip end 1 is fixed with a connection block 7, and the left side of the connection block 7 is fixed with a grinding end 8, and the front of the grinding end 8 is fixed with a second non-slip stripe grip bar 9, and the left side of the grinding end 8 below the second anti-skid stripe grip 9 is fixed with a first catch 10, by holding the second anti-skid stripe grip 9 with the other hand, the second anti-skid stripe grip 9 Under the action, the ope...

Embodiment 2

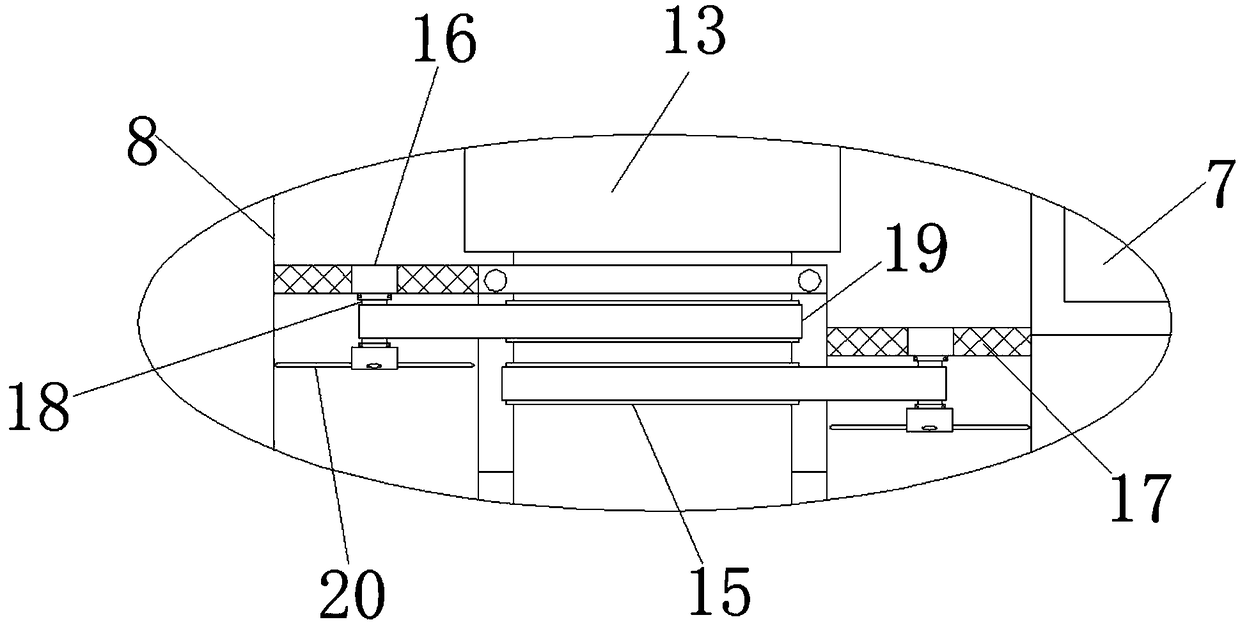

[0024] Example 2, such as figure 1 , 2 , 3 or 4, first connect the external power supply interface 2 to an external power supply to provide power for the device, and then operate the device through the operation button 6. A control chip is arranged inside the operation button 6, and the control chip controls the built-in motor through the operation button 6. 12 rotates, and the built-in motor 12 rotates to drive the output shaft 13 and the grinding sheet 14 to rotate, thereby performing the grinding operation. It will drive the driven shaft 18 and the fan blades 20 to rotate accordingly. Since the speed is very fast, the speed of the fan blades 20 is also very fast, which makes the heat generated by the built-in motor 12 work to be sucked out through the filter screen 17, and then through the through hole 21 discharge, plus the length of the grinding end 8 is less than the length of the grinding sheet 14, so the discharged wind will evenly blow out the debris produced during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com