Wood board cutting device

A cutting device and wood board technology, which is applied in wood processing equipment, special shaping/shaping machines, manufacturing tools, etc., can solve the problems of hard work, increased frequency of saw blade replacement, and uneven edge cutting of wood boards, etc., and achieve the cost of use It will not cause fire, the qualified rate of wood cutting is high, and the workers can work easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings and embodiments, but it is not a basis for limiting the present invention.

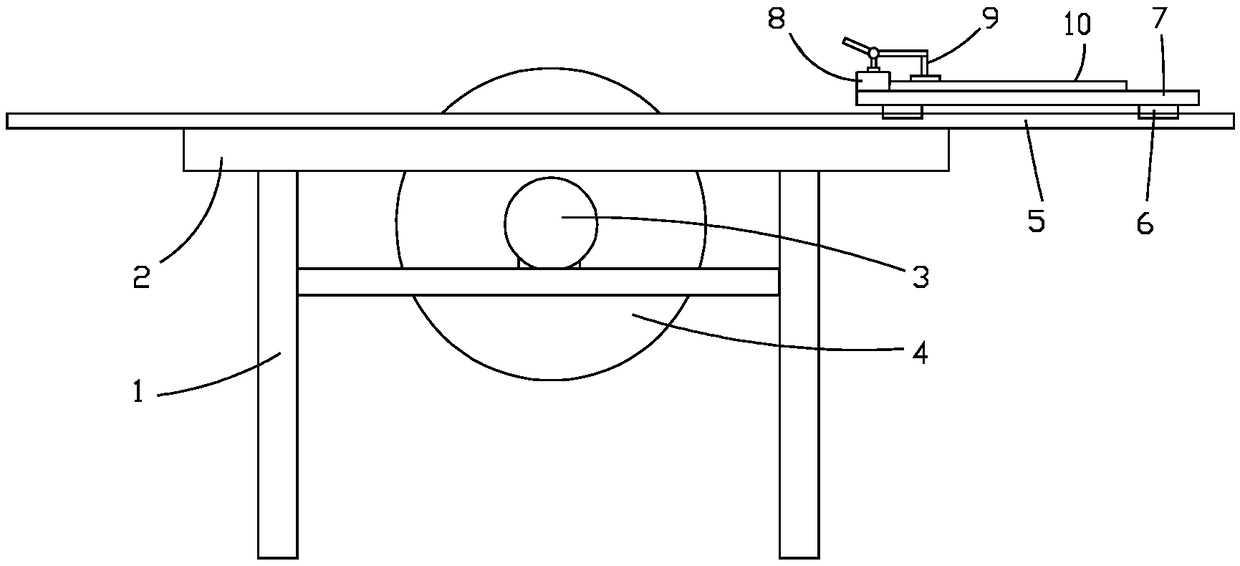

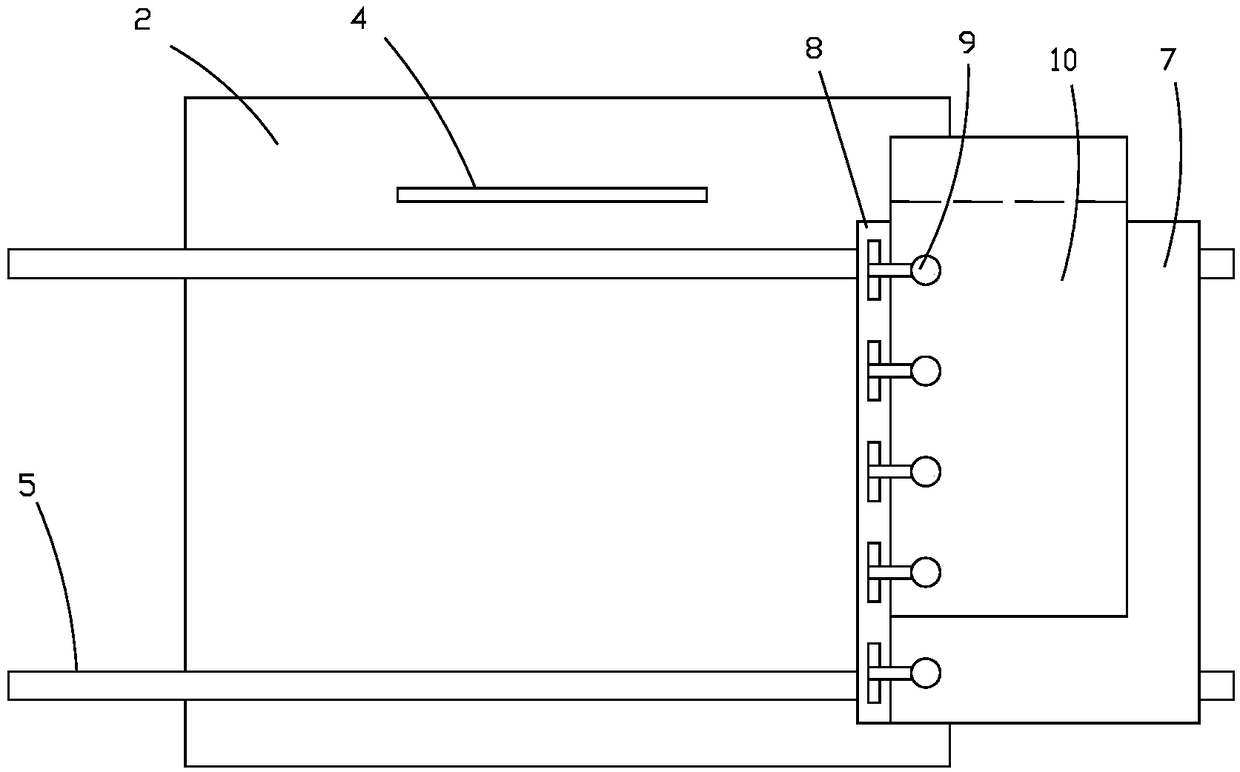

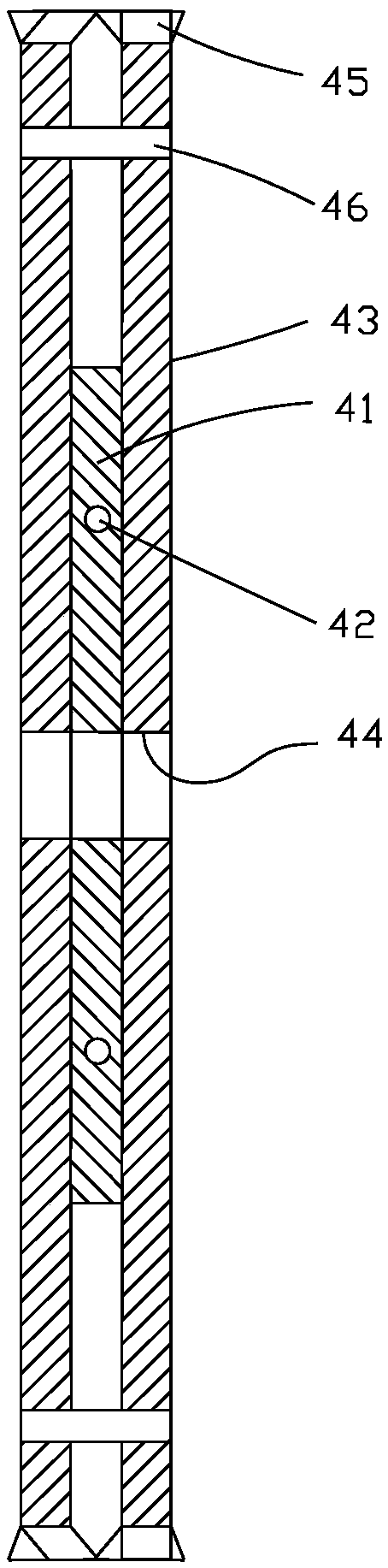

[0014] Examples. Wood cutting device, such as figure 1 As shown, the frame 1 is included. The top of the frame 1 is provided with a platen 2, and the frame 1 is provided with a motor 3 fixed to the frame 1, and the output end of the motor 3 is provided with a saw blade 4 and a saw blade 4 The top passes through the table 2 vertically. Two rails 5 fixed to the table 2 are provided on the same side of the saw blade 4. The rails 5 are connected to the slide plate 7 through the sliding block 6. The slide plate 7 is provided with a backing plate 8 perpendicular to the saw blade 4 , The backing plate 8 is provided with a row of quick clamps 9; the saw blade 4 includes a copper core plate 41, the outer peripheral surface of the copper core plate 41 is provided with a plurality of ventilation holes 42, and both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com