Pitched roof with large-angle and large moving route of plastic mold

A technology with a moving stroke and a large angle, which is applied in the field of advanced manufacturing and automation. It can solve the problems that the inclined roof structure cannot reach 25° and the moving distance of the inclined roof is large, so as to achieve good adaptability, good return on investment, and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

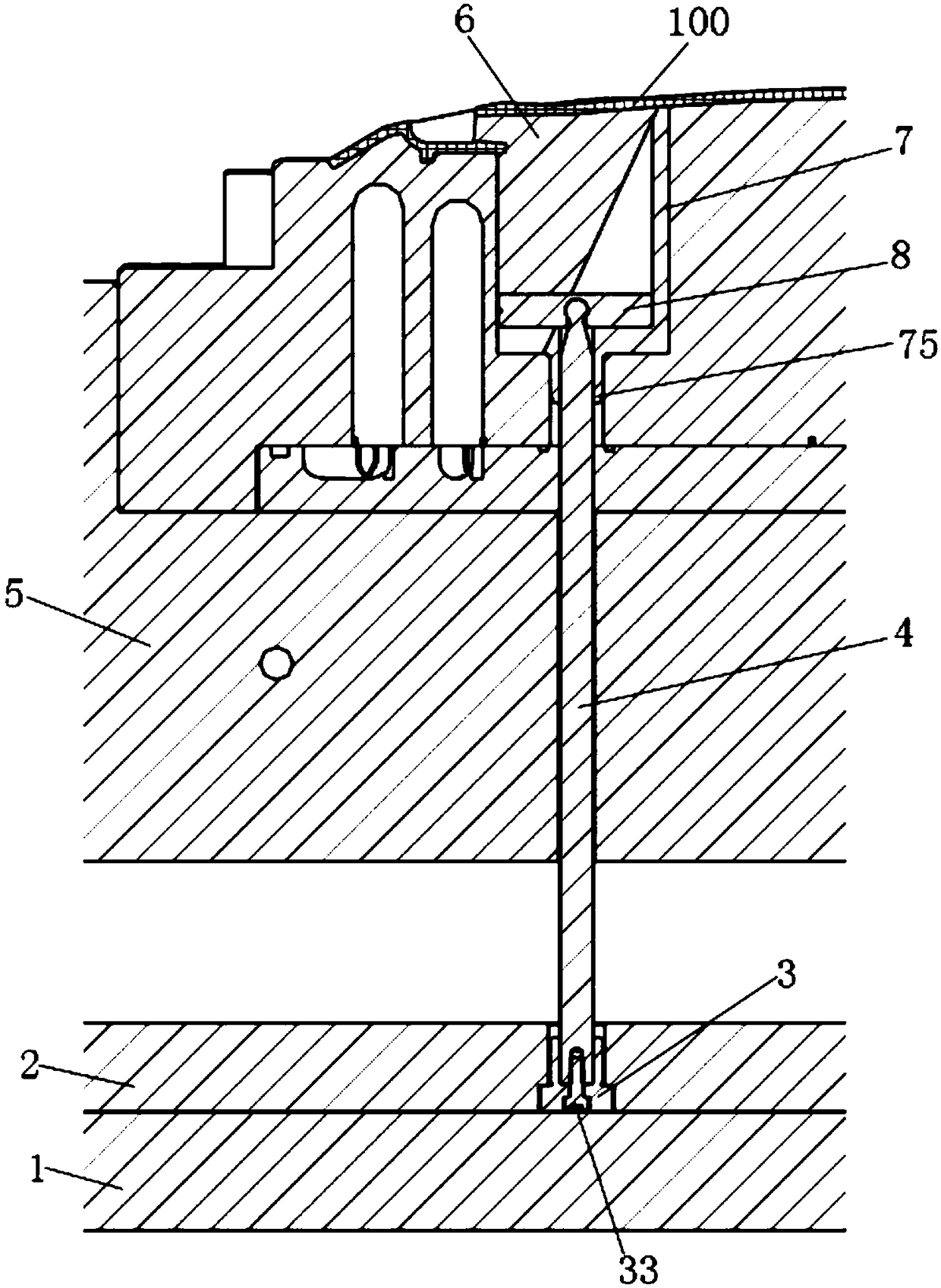

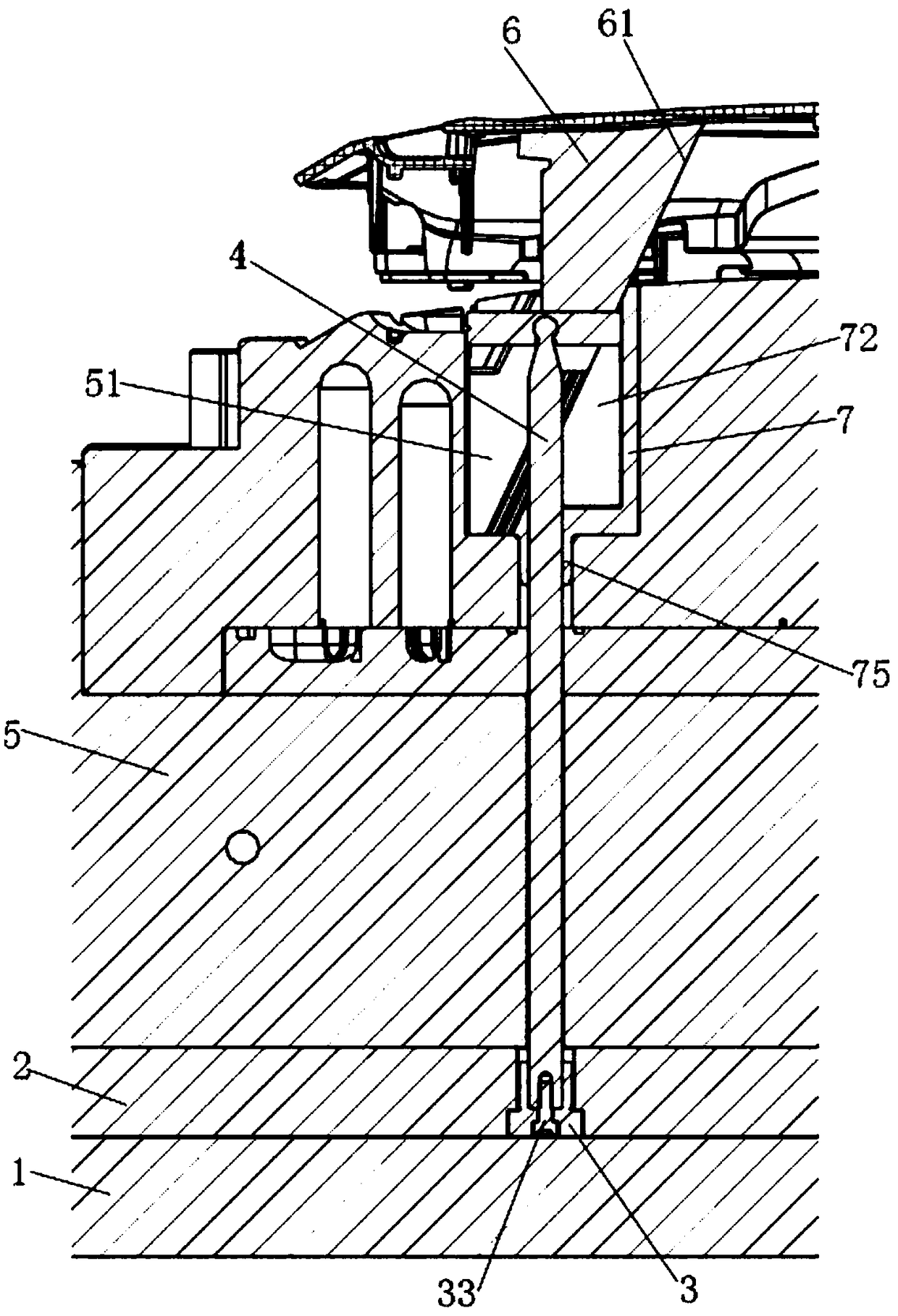

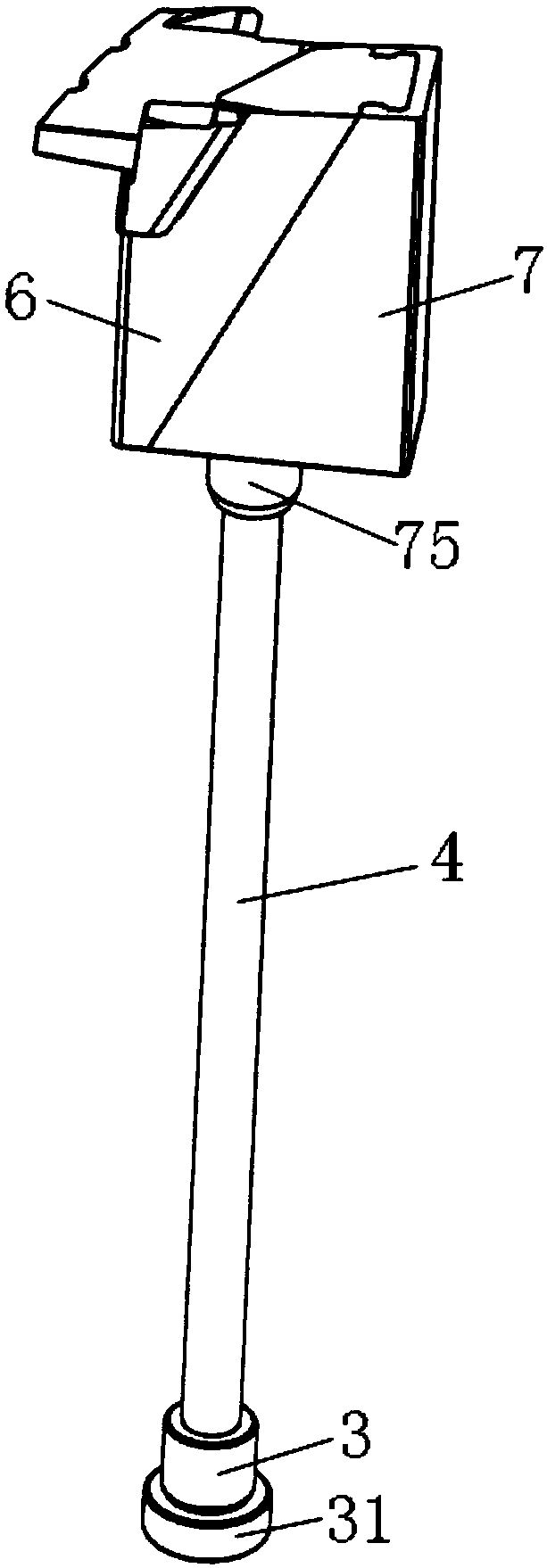

[0028] Such as Figure 1-6The inclined roof with large angle and large movement stroke of the plastic mold shown includes the lower ejector plate 1, the upper ejector plate 2, the first fixing sleeve 3, the ejector rod 4, the lower template 5, the inclined ejector head 6, the inclined ejector angle guide block 7 and Inclined top transverse guide block 8, the upper ejector plate 2 is arranged on the lower ejector plate 1, the first fixed sleeve 3 is arranged in the upper ejector plate 2, and the lower end of the ejector rod 4 is connected with the first fixed sleeve 3 , and the upper end of the ejector rod 4 is arranged in the lower template 5, the upper end of the ejector rod 4 passes through the lower end of the inclined roof angle guide block 7 and is placed in the inclined roof transverse guide block 8, and the inclined roof head 6 is close to the inclined roof One end of the angle guide block 7 is nested in the inclined top angle guide block 7, one end of the inclined top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com