Device for recovering waste metal powder in 3D printing

A waste metal, 3D printing technology, applied in the direction of processing and recycling, manufacturing auxiliary devices, additive processing, etc., can solve the waste of waste powder and other problems, and achieve the effect of saving resources, reducing costs, and high-quality recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

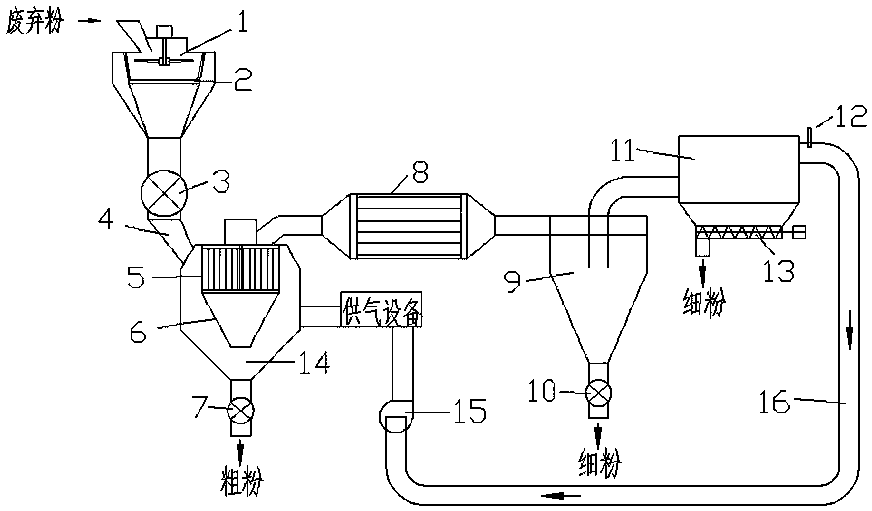

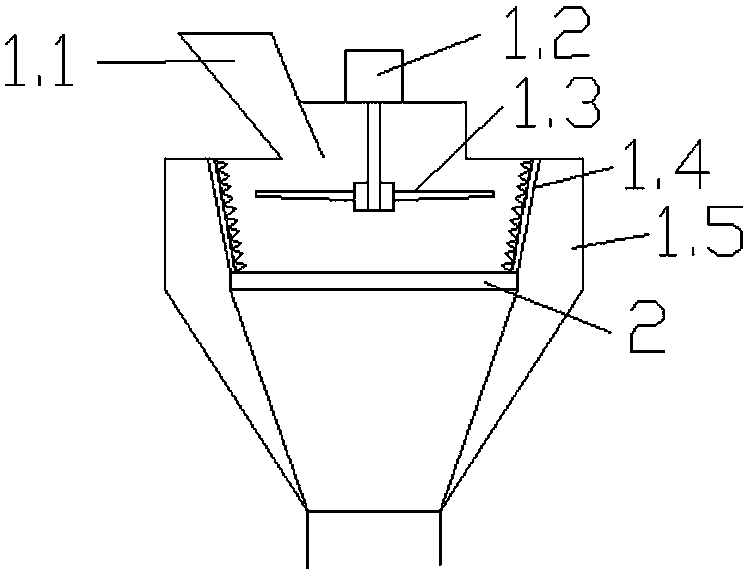

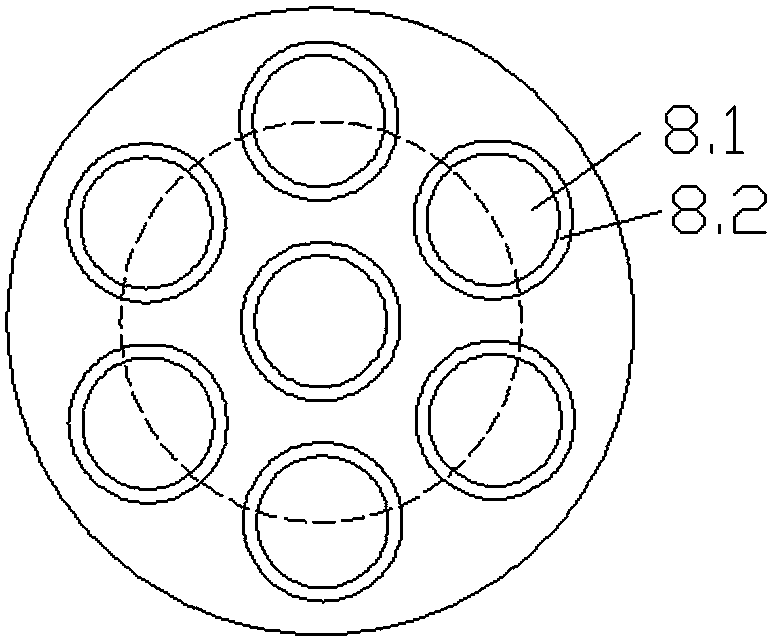

[0016] A device for recycling 3D printing waste metal powder, such as figure 1 As shown, it includes breaking up equipment 1, sorting equipment 14, iron removal equipment 8, collection equipment 9, 11 and gas supply equipment, wherein breaking up equipment such as figure 2 It consists of a breaking disc 1.3 and an inclined counterattack plate 1.4. The breaking disc 1.3 is driven by a motor 1.2. The surface of the inclined counterattack plate 1.4 is processed with triangular rib-shaped protrusions. The triangular rib-shaped protrusions on the inclined counterattack plate 1.4 can increase the The impact on the powder particles is to separate the metal powder bonded together due to the moisture in the air or other factors as much as possible; the vibrating screen 2 is set under the inclined counter-attack plate 1.4 to disperse the periphery of the equipment 1 A sound insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com