Energy-storing type automobile in-situ turning machine

A U-turn machine and energy storage technology, which is applied in vehicle maintenance, shunting equipment, vehicle control devices, etc., can solve the problems of limited expansion space and high cost, and achieve the effect of alleviating parking difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

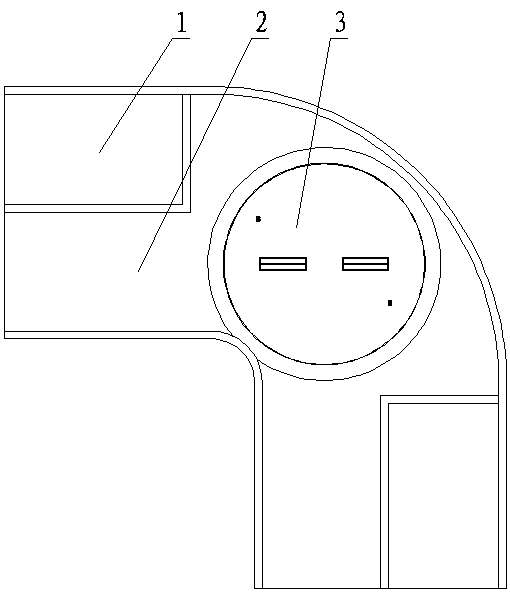

[0023] As shown in the figure, the vehicle turn-around machine 3 is located at the turning of the ground road 2, and is generally arranged on the inner side of the turning of the ground road 2.

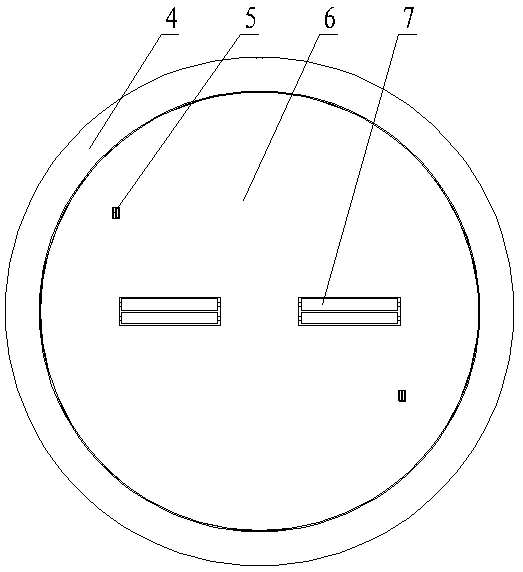

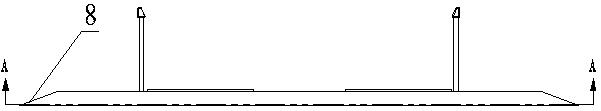

[0024] The edge of the chassis 4 of the automobile in-situ U-turn machine 3 is provided with a slope 8, which is convenient for the vehicle to enter and exit; rotate.

[0025] Controller 5 is located at the left front end, the right rear end of turntable assembly 6 respectively, and is used for the vehicle that two-way enters, and people just needn't get off to make arrangements for.

[0026] A positioner 9 is set on the back of the turntable of the turntable assembly 6, and the positioner 9 will stop the brake when the turntable assembly 6 rotates to the set angle according to the setting of the controller 5.

[0027] The energy storage drum 7 in the accumulator 13 is located at both sides in the middle of the turntable assembly 6 , the energy storage drum 7 is connected with the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com