Hammer head special for hammer crusher and preparation method thereof

The technology of hammer crusher and hammer head is applied in the field of preparation of hammer head for hammer crusher and hammer head for hammer crusher, which can solve the problems of time-consuming, labor-intensive, low production efficiency, and wear and tear of hammer head for replacement parts, etc. The effect of saving maintenance costs, extending service life and improving product characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

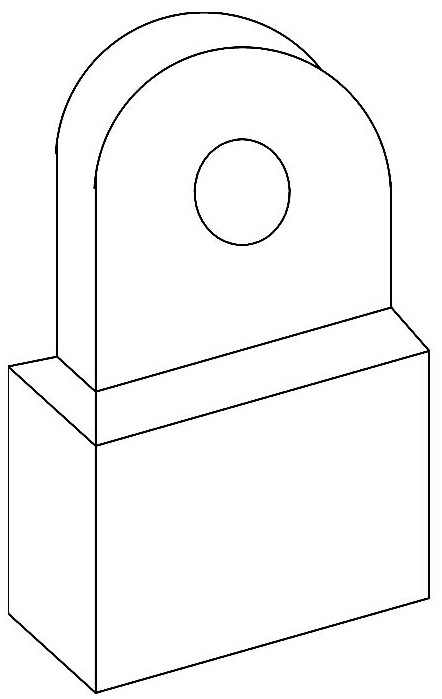

Image

Examples

Embodiment Construction

[0015] The special hammerhead for hammer breaking machine of the present invention has the ratio of raw materials: 91%~93%, carbon black 2~2.5%, binder 2~2.5%, titanium carbide 0.25~0.5%, chromium carbide 0.25~0.5% , pure water 2.5~3.5%.

[0016] In actual preparation, in order to ensure that the quality of the hammer meets the requirements for use, the tungsten carbide content in the tungsten carbide raw material is ≥99%, and its particle size is 8-10 μm; the carbon black is high-purity carbon black, and its ash content is <0.01%; the titanium carbide raw material The titanium content in the medium is ≥99.5%, and its particle size is 5~7μm; the chromium content in the chromium carbide raw material is ≥99.5%, and its particle size is 5~7μm; the conductivity of pure water is less than 10μs / cm. The binder is polyvinylpyrrolidone with a viscosity of 39.5~45.8 mpa.s.

[0017] The preparation method of hammer head special for hammer breaker of the present invention comprises the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com