Fe/Mo nano multilayer film and preparation method thereof

A nano-multi-layer and preparation process technology, which is applied in coating, metal material coating process, ion implantation plating, etc., can solve the problem that the hard metal nano-multi-layer film is not easy to prepare, not suitable for anti-friction applications of machinery and equipment, and has no Rising tribology application research and other issues, to achieve the effect of reliable performance, excellent mechanical properties, and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

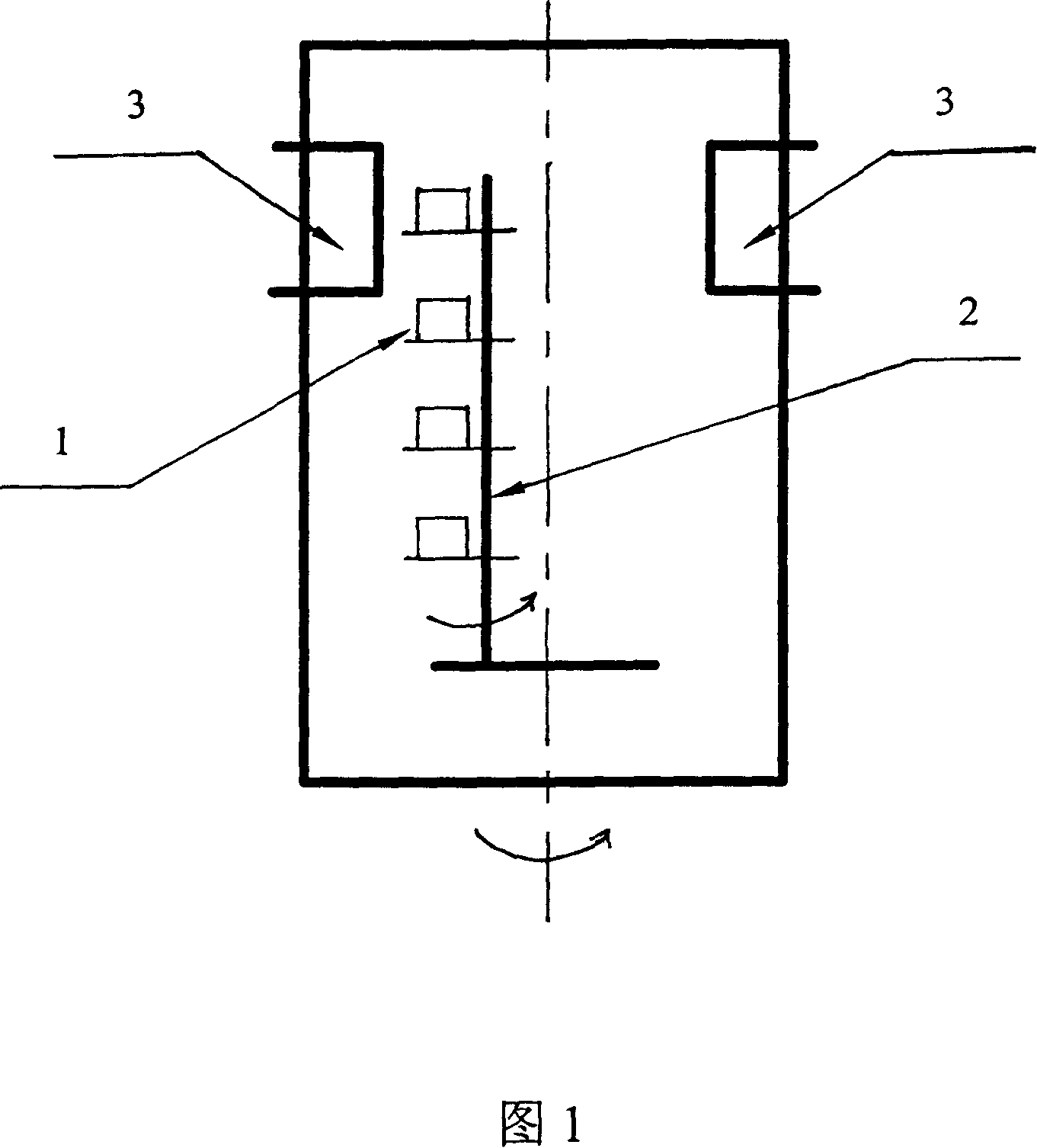

[0032] Mo target and Fe target are respectively placed at the two target source positions;

[0033] The purity of the target material used is: Fe target 90-99.99%; Mo target 90-99.95%;

[0034] The substrate is heated to: 50℃ before coating;

[0035] The working gas is: 99.999% high-purity Ar gas;

[0036] Vacuum degree: 2×10 -4 Pa;

[0037] Working air pressure: 2×10 -2 Pa;

[0038] Negative bias is applied to improve deposition efficiency: 50V;

[0039] Setting voltage: 500V, current 100mA, self-bias 450V, sputtering power 100W;

[0040] When depositing the Mo layer, the residence time of the substrate in front of the Mo target is 9.37 seconds, and the deposition rate is 16 nm / min;

[0041] When depositing the Fe layer, the matrix stays in front of the Fe target for 10 seconds, and the deposition rate is 15 nm / min;

[0042] The thickness of the final Fe / Mo nano-multilayer film bilayer is 5 nm.

Embodiment 2

[0044] Mo target and Fe target are respectively placed at the two target source positions;

[0045] The purity of the target material used is: Fe target 90-99.99%; Mo target 90-99.95%;

[0046] The substrate is heated to: 100℃ before coating;

[0047] The working gas is: 99.999% high-purity Ar gas;

[0048] Vacuum degree: 1×10 -2 Pa;

[0049] Working air pressure: 5×10 -1 Pa;

[0050] Negative bias is applied to improve deposition efficiency: 120V;

[0051] Setting voltage: 800V, current 220mA, self-bias 750V, sputtering power 200W;

[0052] When depositing the Mo layer, the substrate stays in front of the Mo target for 25 seconds, and the deposition rate is 12 nm / min;

[0053] When depositing the Fe layer, the matrix stays in front of the Fe target for 40 seconds, and the deposition rate is 7.5 nm / min;

[0054] The thickness of the final Fe / Mo nano-multilayer film bilayer is 10 nm.

Embodiment 3

[0056] Mo target and Fe target are respectively placed at the two target source positions;

[0057] The purity of the target material used is: Fe target 90-99.99%; Mo target 90-99.95%;

[0058] The substrate is heated to: 150℃ before coating;

[0059] The working gas is: 99.999% high-purity Ar gas;

[0060] Vacuum degree: 2×10 -2 Pa;

[0061] Working air pressure: 2×10 0 Pa;

[0062] Negative bias is applied to improve deposition efficiency: 200V;

[0063] Setting voltage: 1000V, current 400mA, self-bias 950V, sputtering power 300W;

[0064] When depositing the Mo layer, the residence time of the substrate in front of the Mo target is: 100 seconds, and the deposition rate is 6 nm / min;

[0065] When depositing the Fe layer, the matrix stays in front of the Fe target for 100 seconds, and the deposition rate is 6 nm / min;

[0066] The thickness of the final Fe / Mo nano-multilayer film bilayer is 20 nm.

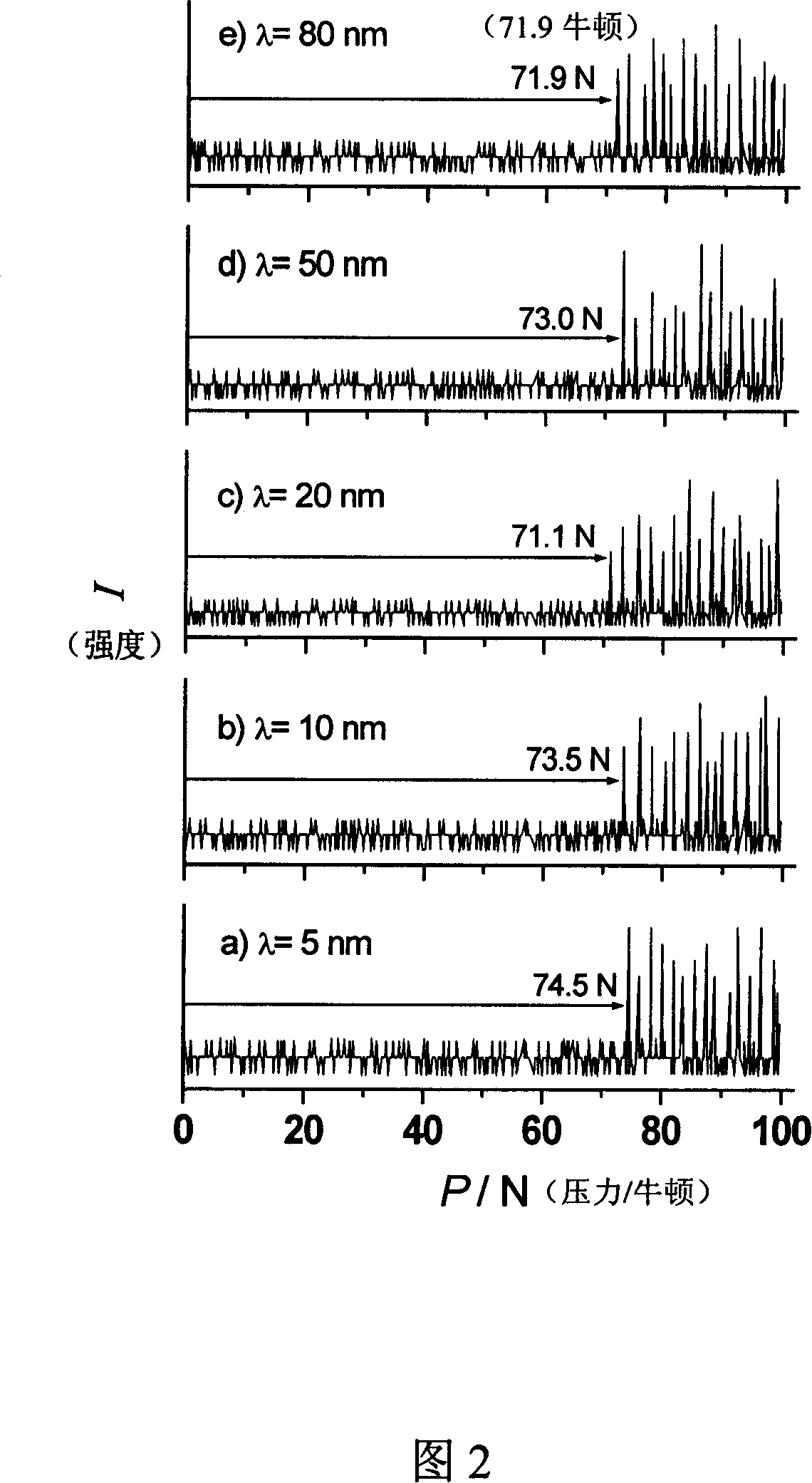

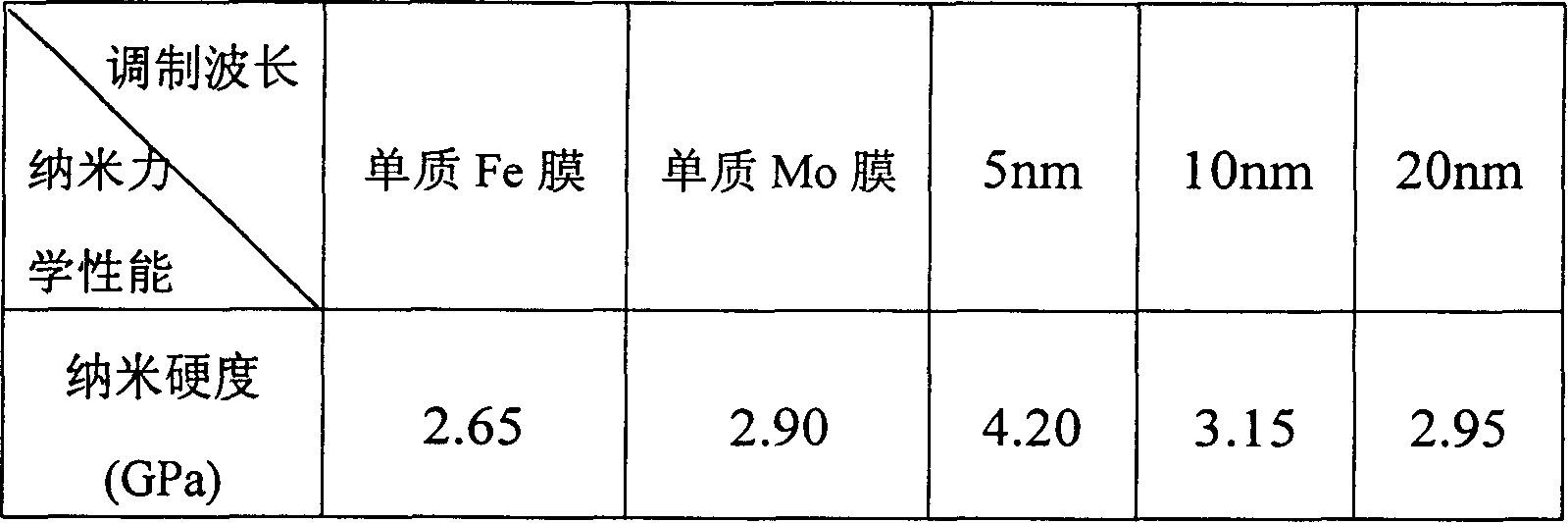

[0067] After testing, the mechanical property parameters of the Fe / Mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com