Head-on protective fence

A kind of technology of protective fence and protective net, applied in the direction of fence, building type, building, etc., can solve the problems of tension of nylon net, weak nylon net, poor protective effect, etc., to ensure personnel safety, simple structure and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

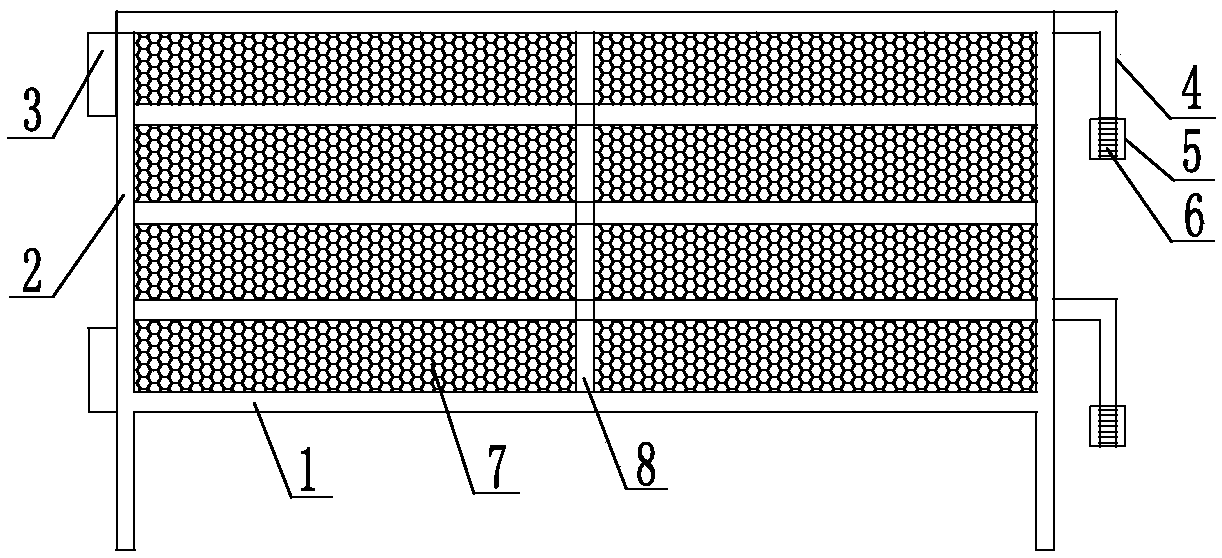

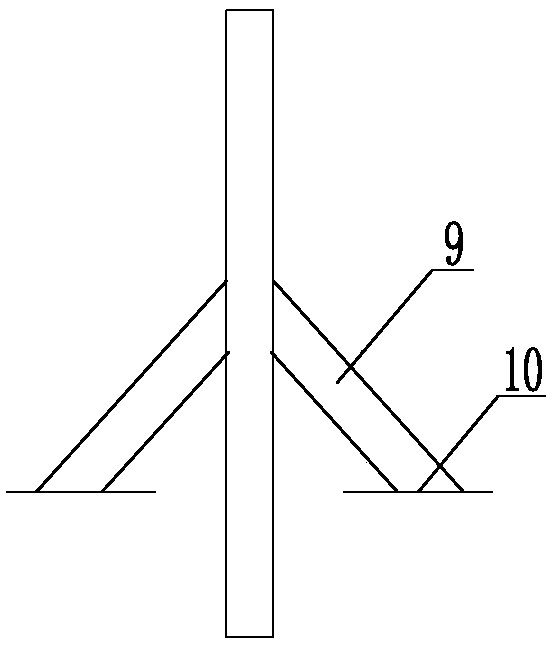

[0019] Such as Figure 1-2 As shown, the head-on guardrail includes a railing body, and the railing body includes a cross bar 1 and vertical bars 2 at both ends. A reinforcement bar 8 is vertically welded on the bar 1, and a protective net 7 is installed on the surface of the railing body. One end of the railing body is provided with a jack 3, and the other end of the railing body is provided with an insertion rod 4, and the insertion rod 4 is connected to the jack. 3 cooperate with each other, the lower end of the insertion rod 4 is provided with a thread 5, and is connected with a safety block 6 through the thread 5, and a leg 9 is installed on the side of the railing body, and the end of the leg 9 is connected to a support plate 10.

[0020] The material of the horizontal bar 1, the vertical bar 2 and the reinforcement bar 8 is galvanized steel pipe, and the diameter of the galvanized steel pipe is 15 cm.

[0021] The length of the vertical bar 2 is 2.2 meters, and the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com