A rubber cartridge assembly for a packer

A technology of packer and rubber cartridge, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc. It can solve the problem of shoulder structure damage, packer setting failure, and downhole annulus loss of sealing effect and other issues, to achieve good structural strength and ductility, enhance long-term performance and sealing performance, and enhance the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

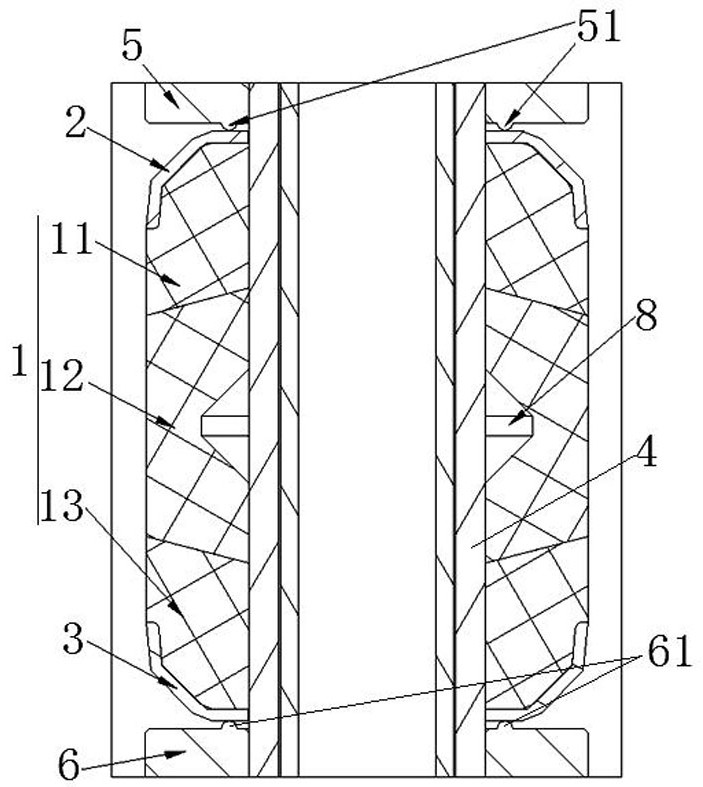

[0025] see figure 1 As shown, the present invention includes a rubber cylinder body 1, an upper protection bowl 2 and a lower protection bowl 3.

[0026] Among them, the rubber cylinder body 1 is composed of the upper section 11 of the rubber cylinder body, the middle section 12 of the rubber cylinder body and the lower section 13 of the rubber cylinder body formed by axial segmentation, the upper section 11 of the rubber cylinder body, the middle section 12 of the rubber cylinder body and the The lower section 13 of the rubber body is made of rubber material resistant to high temperature and high pressure difference. Of course, the upper section 11 of the rubber cylinder body, the middle section 12 of the rubber cylinder body and the lower section 13 of the rubber cylinder body are made of rubber materials with the same performance. The upper section 11 of the rubber cylinder body, the middle section 12 of the rubber cylinder body and the lower section 13 of the rubber cylind...

Embodiment 2

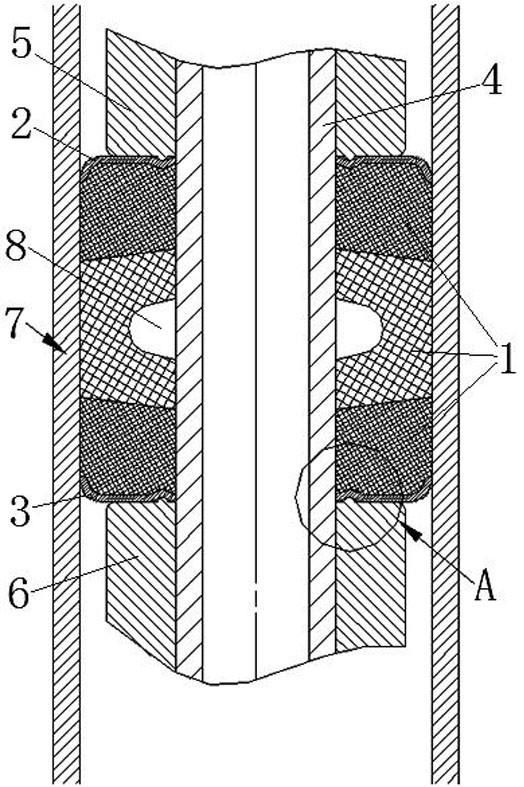

[0032] The invention comprises a rubber cylinder body, an upper protection bowl and a lower protection bowl.

[0033] Among them, the rubber cylinder body is composed of the upper section of the rubber cylinder body, the middle section of the rubber cylinder body and the lower section of the rubber cylinder body which are axially segmented. 1. Made of rubber material resistant to high pressure difference. Of course, usually the upper section of the rubber cylinder body, the middle section of the rubber cylinder body and the lower section of the rubber cylinder body adopt the rubber material with the same performance. The upper section of the rubber cylinder body, the middle section of the rubber cylinder body and the lower section of the rubber cylinder body are combined together in direct contact with each other according to the axial sequence. Low slope structure, the direct contact between the middle section of the rubber cylinder body and the lower section of the rubber cy...

Embodiment 3

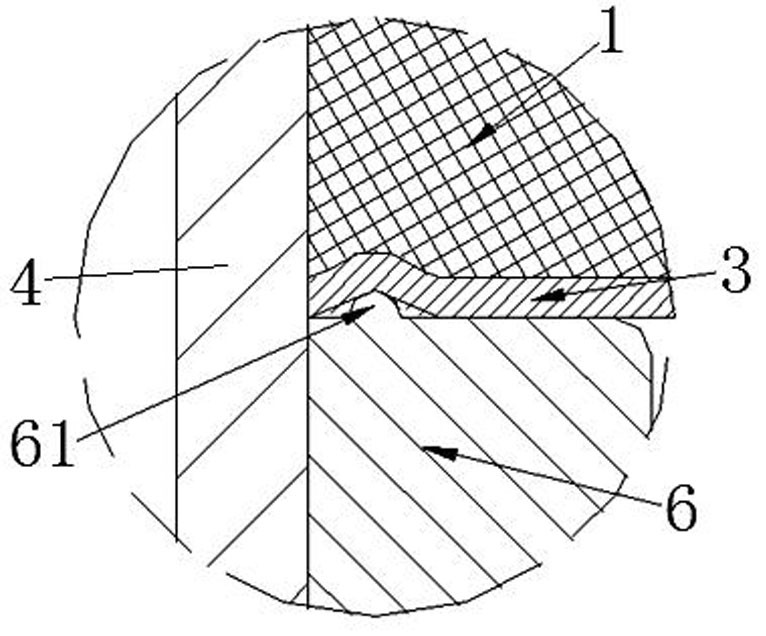

[0039] The invention comprises a rubber cylinder body, an upper protection bowl and a lower protection bowl.

[0040] Among them, the rubber cylinder body is composed of the upper section of the rubber cylinder body, the middle section of the rubber cylinder body and the lower section of the rubber cylinder body which are axially segmented. 1. Made of rubber material resistant to high pressure difference. Of course, usually the upper section of the rubber cylinder body, the middle section of the rubber cylinder body and the lower section of the rubber cylinder body adopt the rubber material with the same performance. The upper section of the rubber cylinder body, the middle section of the rubber cylinder body and the lower section of the rubber cylinder body are combined together in direct contact with each other according to the axial sequence. Low slope structure, the direct contact between the middle section of the rubber cylinder body and the lower section of the rubber cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com