A kind of sandwich metal plate and its riveting forming method

A metal sheet and forming method technology, applied in the direction of sheets/boards, building components, etc., can solve the difficulty of increasing the development of high-precision sandwich metal sheets, affect the surface flatness of sandwich structure metal sheets, and protect the panels. Firmly fixed and other issues to achieve the effect of enhancing reliability and practicability, high yield of finished products, and simplifying the difficulty of molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

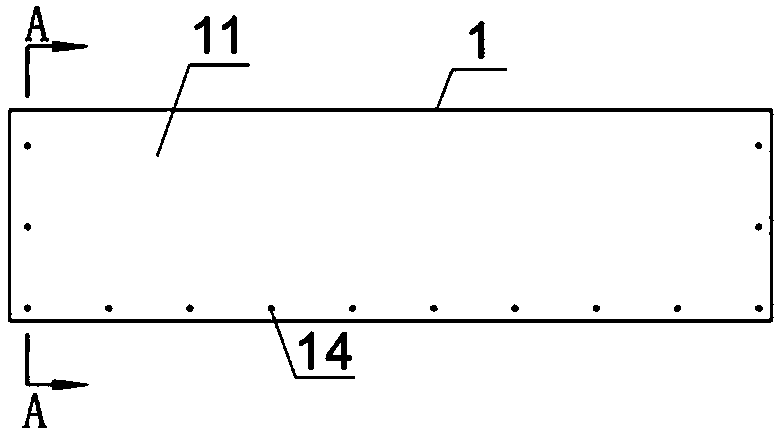

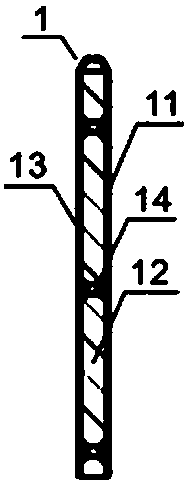

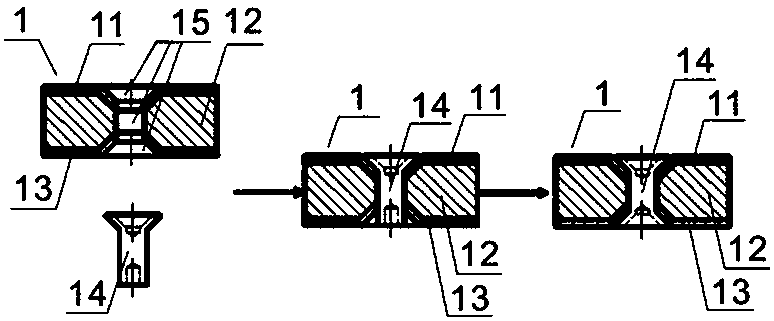

[0041] see figure 1 and figure 2 As shown, the sandwich metal sheet of the present invention has a sheet body 1 . The plate body 1 is a rectangular structure with a length of about 300mm, a width of about 80mm, and a thickness of about 6-7mm. Panel 13 is composed.

[0042] Wherein, the middle plate 12 is a steel plate with a thickness of about 5 mm. The thickness of the middle plate 12 is greater than the thickness of the first panel 11 and the second panel 13 respectively. The two surfaces of the middle plate 12 are required to be flat and smooth respectively.

[0043] The thickness of the first panel 11 and the second panel 13 are equal, and their thicknesses are about 0.6mm respectively. The surface area of the first panel 11 and the second panel 13 substantially matches the surface area of the middle panel 12 . The first panel 11 and the second panel 13 are an integral structure, and they are bent into a U shape on one long side relative to the middle plate 12. ...

Embodiment 2

[0076] The sandwich metal sheet of the invention has a sheet body. The plate body is a rectangular structure with a length of about 300mm, a width of about 80mm, and a thickness of about 6-7mm. It is mainly composed of a first panel, a middle panel and a second panel that are sequentially riveted together by a plurality of rivets.

[0077] Wherein, the middle plate is a steel plate with a thickness of about 5mm. The thickness of the middle plate is respectively greater than the thickness of the first panel and the second panel. The two surfaces of the middle plate are required to be flat and smooth respectively.

[0078] The thickness of the first panel and the second panel are equal, and their thicknesses are about 0.8mm respectively. The panel areas of the first panel and the second panel substantially match the panel area of the middle panel. The two surfaces of the first panel and the second panel are required to be flat and smooth respectively, and the flatness of th...

Embodiment 3

[0096] The sandwich metal sheet of the invention has a sheet body. The plate body is a square structure with a side length of about 200mm and a thickness of about 7-8mm. It is mainly composed of a first panel, a middle panel and a second panel which are sequentially riveted together by a plurality of rivets.

[0097] Wherein, the middle plate is a steel plate with a thickness of about 6mm. The thickness of the middle plate is respectively greater than the thickness of the first panel and the second panel. The two surfaces of the middle plate are required to be flat and smooth respectively.

[0098] The thickness of the first panel and the second panel are equal, and their thicknesses are about 0.7mm respectively. The panel areas of the first panel and the second panel substantially match the panel area of the middle panel. The two surfaces of the first panel and the second panel are required to be flat and smooth, and the flatness of the outer surfaces of the first panel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com