Armature assembly structure of horizontal magnetic circuit relay

An assembly structure and relay technology, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems such as affecting the service life, unfavorable service stability of horizontal magnetic circuit relays, and reducing the magnetic area of the armature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

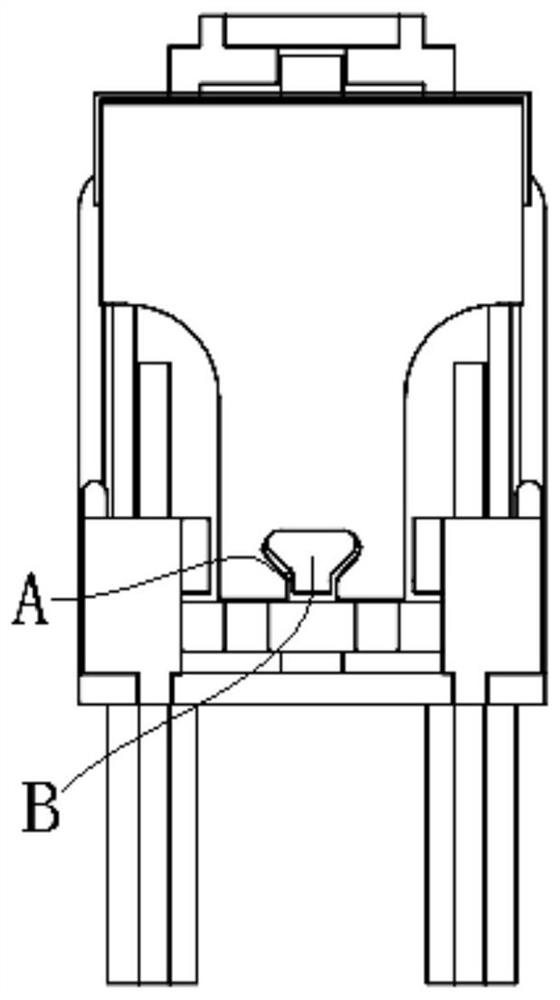

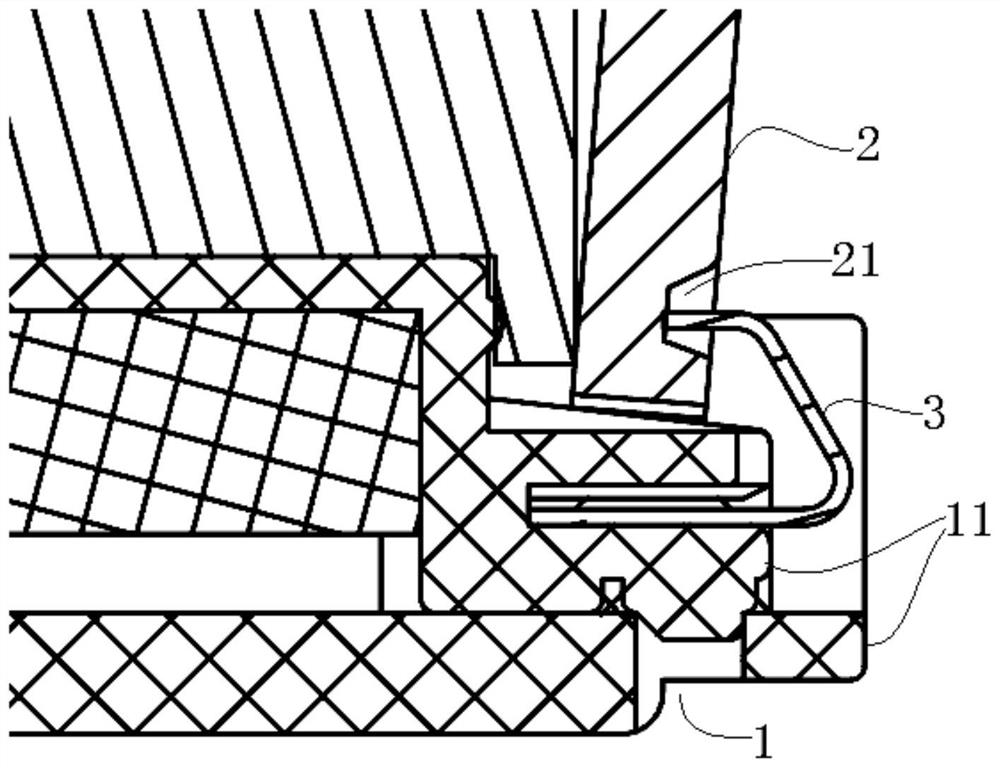

[0033] see image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 with Figure 11 As shown, the present invention is an armature assembly structure of a horizontal magnetic circuit relay, including an armature 2, a compression spring 3, and a base 11 for assembling the armature 2 and the compression spring 3.

[0034] Specifically, based on the structural particularity of the horizontal magnetic circuit relay, the base 11 is formed at the bottom of one end of the coil frame 1 , and the base 11 may be integrally formed with the coil frame 1 or may be a separate assembly structure.

[0035] The inside of the base 11 is provided with a compression spring insertion groove 12 for assembling the compression spring 3 , and the notch of the compression spring insertion groove 12 is formed at the outer end surface of the base 11 . The top of the base 11 has a recessed space for assembling the armature 2 (that is, the armature assembly space...

Embodiment 2

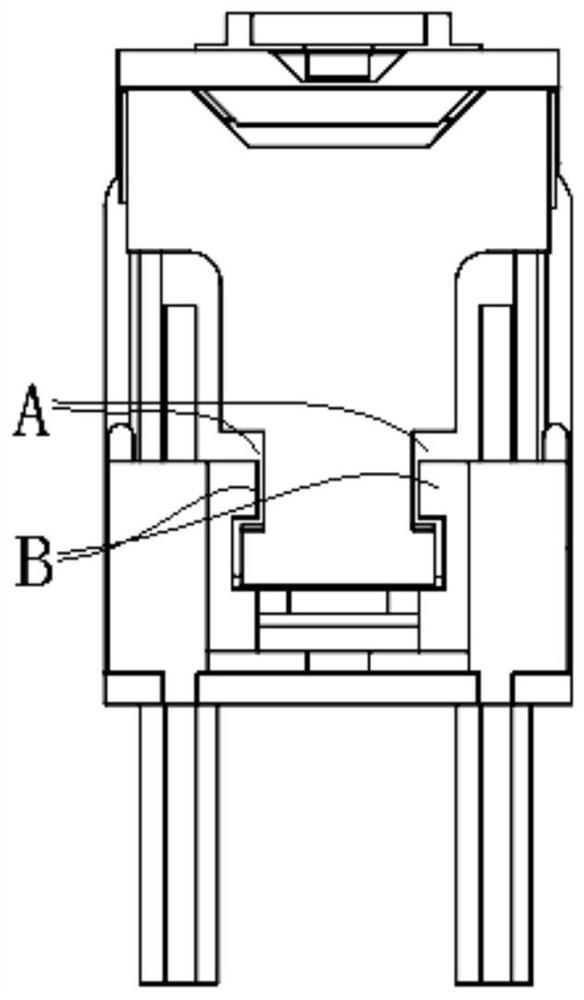

[0049] The invention relates to an armature assembly structure of a horizontal magnetic circuit relay, comprising an armature, a compression spring, and a base for assembling the armature and the compression spring.

[0050] Specifically, based on the structural particularity of the horizontal magnetic circuit relay, the base is formed at the bottom of one end of the coil frame, and the base can be an integrally formed structure with the coil frame or a separate assembly structure.

[0051] The inside of the base is provided with a compression spring insertion groove for assembling the compression spring, and the notch of the compression spring insertion groove is formed at the outer end surface of the base. The top of the base has a recessed space for assembling the armature (that is, the armature assembly space), and the two sides of the armature assembly space have other necessary structures that protrude upwards, but there is no armature assembly space on both sides of the ...

Embodiment 3

[0064] The other content of this embodiment is the same as that of Embodiment 1 or 2, the difference is that: the bottom surface of the armature assembly space of the base is a plane structure, the bottom edge of the armature is a plane straight edge structure, and the armature is in the armature assembly space of the base in a straight line. Edge contact mate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com