A lightning-proof wind turbine blade

A technology for wind turbines and blades, which is applied in the field of components of wind turbines. It can solve problems such as structural damage to the blade itself, failure of the grounding structure, and high technical difficulty. It achieves excellent lightning conduction effects, easy manufacturing and molding, and low technical difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

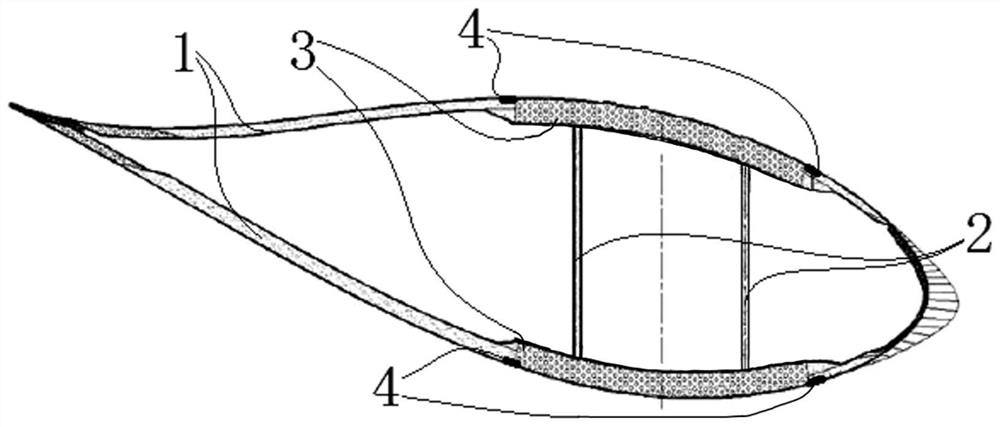

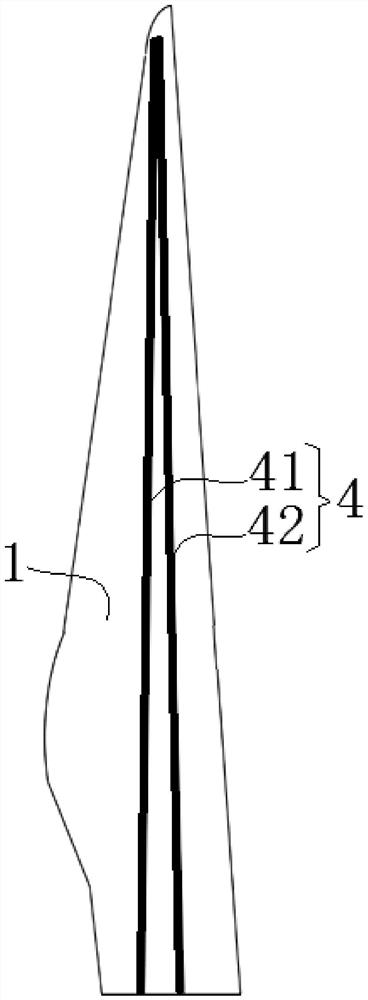

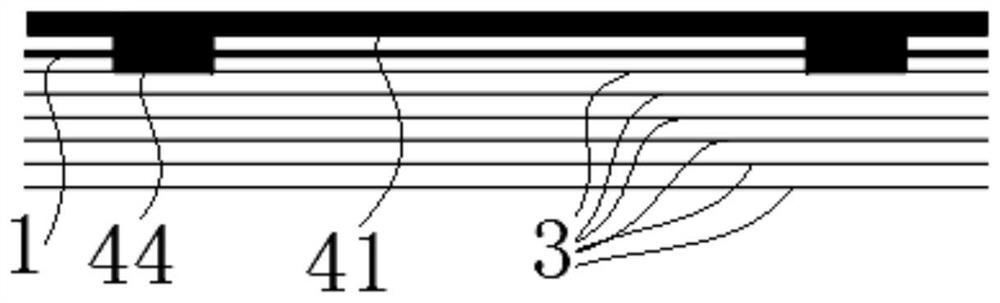

[0038] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes a blade shell 1 and two sets of conduction assemblies 4 .

[0039]Wherein, the blade shell 1 is surrounded by arc-shaped halves on both sides, and has an abdominal cavity. In the abdominal cavity of the blade shell 1, a web 2 supporting the arc-shaped halves on both sides is provided. The two ends of the web 2 are respectively provided with spar caps 3 of carbon fiber structure, that is, the ends of the web 2 are connected by the corresponding spar caps 3. Form a connection with the corresponding arc-shaped half. In this way, there are two sets of spar caps 3 of carbon fiber structure in the abdominal cavity of the blade shell 1, see figure 2 shown.

[0040] The structures of the two groups of conducting assemblies 4 are basically the same, and the arrangement positions of the two groups of conducting assemblies 4 on the blade shell 1 correspond to the position...

Embodiment 2

[0063] see Figure 6 As shown, the present invention includes a blade shell 1 and two sets of conduction assemblies 4 .

[0064] Wherein, the blade shell 1 is surrounded by arc-shaped halves on both sides, and has an abdominal cavity. In the abdominal cavity of the blade shell 1, there are webs supporting the arc-shaped halves on both sides. The two ends of the webs are respectively provided with carbon fiber structure spar caps, that is, the ends of the webs are connected to the corresponding arc-shaped fins through the corresponding spar caps. The halves form the connection. In this way, there are two sets of spar caps of carbon fiber structure in the abdominal cavity of the blade shell 1 .

[0065] The structures of the two groups of conduction assemblies 4 are basically the same, and the arrangement positions of the two groups of conduction assemblies 4 on the blade shell 1 correspond to the positions of the two sets of spar caps in the abdominal cavity. A one-to-one ma...

Embodiment 3

[0088] The invention includes a blade shell and two sets of conduction assemblies.

[0089] Wherein, the blade shell is surrounded by arc-shaped halves on both sides, and has an abdominal cavity. In the abdominal cavity of the blade shell, there are webs supporting the arc-shaped halves on both sides. The two ends of the webs are respectively provided with carbon fiber structure spar caps, that is, the ends of the webs are connected to the corresponding arc-shaped halves through the corresponding spar caps. The body forms a connection. In this way, there are two sets of spar caps of carbon fiber structure in the abdominal cavity of the blade shell.

[0090] The structures of the two groups of conduction components are basically the same. The arrangement positions of the two groups of conduction components on the blade shell correspond to the positions of the two sets of spar caps in the abdominal cavity. Form a one-to-one correspondence relationship.

[0091] Now take the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com