One-hole multi-purpose construction method for controlling impact and gas disaster of deeply buried coal seam.

A construction method and technology for coal seams, which are applied in gas discharge, earth-moving drilling, safety devices, etc., can solve problems such as unreasonable spacing, low utilization rate of drilling holes, and inefficient disaster management, and achieve the effect of high-efficiency pressure relief and anti-scouring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

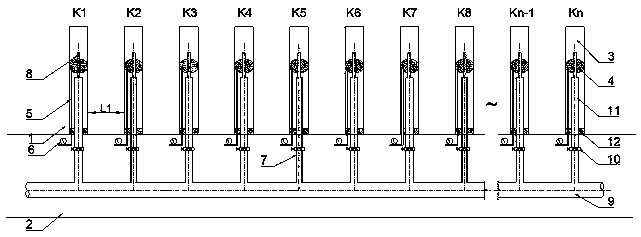

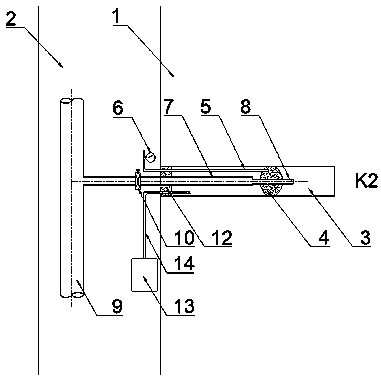

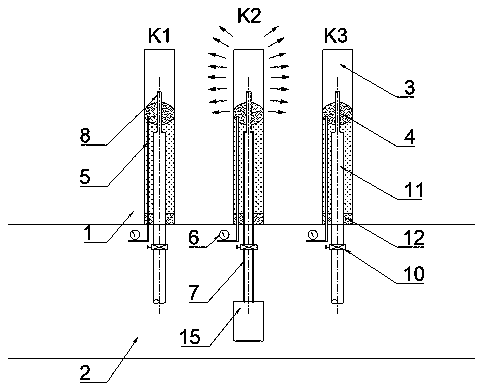

[0035] This embodiment provides a multi-purpose construction method for controlling the impact and gas disasters of deep-buried coal seams, including implementing the following steps in deep-buried coal seams with a buried depth greater than 600m and simultaneous rockburst and gas disasters:

[0036] (1) Use conventional methods to test the effective radius R1 of coal seam gas drainage at mining face 1, such as the existing mature methods for testing the radius of gas drainage such as gas pressure reduction method and gas flow test method. Use conventional methods to test the effective pressure relief radius R2 of the anti-scouring borehole in the mining face 1, such as stress reduction method, electromagnetic radiation method and other mature methods for testing the effective pressure relief radius of the borehole. Analyze and compare the values of R1 and R2, and select twice the smaller value as the distance L1 between two adjacent boreholes in mining face 1.

[0037] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com