Mobile phone spare and accessory part baking assembly line

A spare parts and assembly line technology, applied in the field of mobile phone spare parts production, can solve the problems of increasing production cost, reducing production efficiency, insufficient baking degree, etc., and achieve the effect of increasing production cost, reducing production efficiency and speeding up baking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

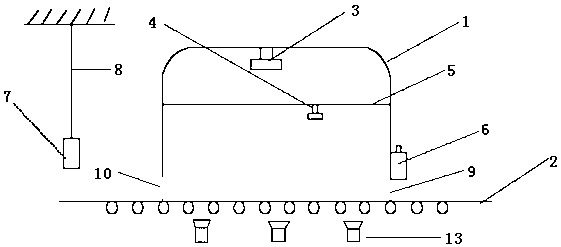

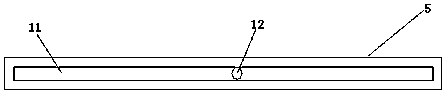

[0013] Example: such as figure 1 and figure 2 As shown, a mobile phone spare parts baking line is composed of a baking oven 1 and a transmission device 2, the transmission device 2 includes a conveyor belt and a transmission wheel, the baking oven 1 is arranged above the conveyor belt, and the oven 1 is provided with an inlet 9 and outlet 10, a heater 3 is arranged on the top of the oven 1, and the heater 3 is connected to the host computer, and the heater 3 is controlled by a program set by the host computer to increase or decrease the temperature, and the middle position of the oven 1 is provided with a cross The guide rail 5 of the baking oven 1, the guide rail 5 is provided with a track 11, a slide block 12 is installed on the track 11, the slide block 12 can slide freely back and forth in the track 11, a fan-4 is fixedly arranged on the slide block 12, and the baking oven 1 The outside of the power switch 6 is also provided with a power switch 6, and the power switch 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com