Creep damage calculation method and model under variable load history

A calculation method and variable load technology, which can be used in calculation, application of stable tension/pressure to test material strength, special data processing applications, etc., which can solve the problems of acceleration task test spectrum compilation and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

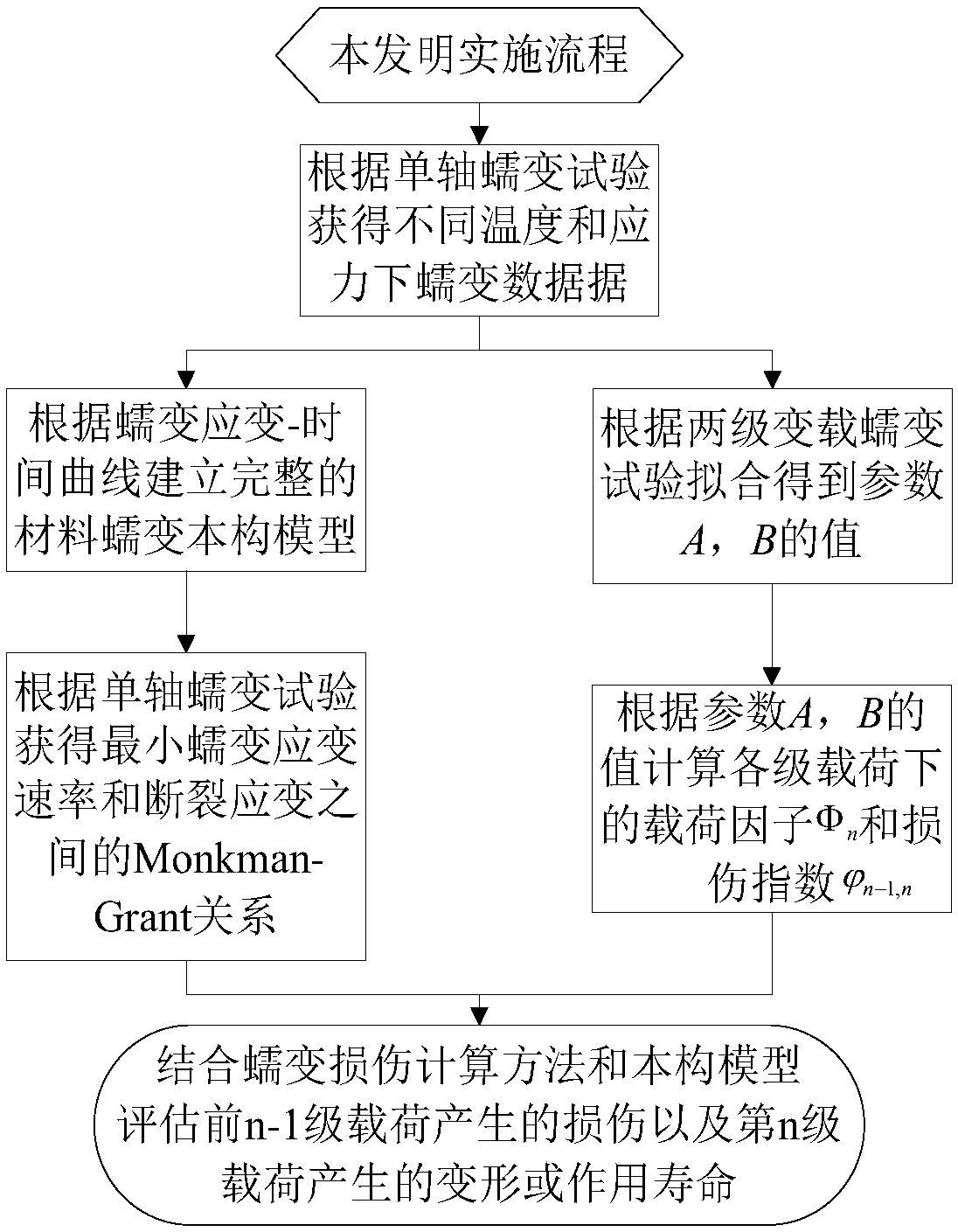

[0048] Below in conjunction with practical application example and accompanying drawing, the present invention will be further described:

[0049] The present invention relates to a creep damage calculation method under variable load history, and its implementation process is as attached figure 1 As shown, its application in the creep damage calculation of TC11 titanium alloy material at 500 °C under variable load includes the following steps:

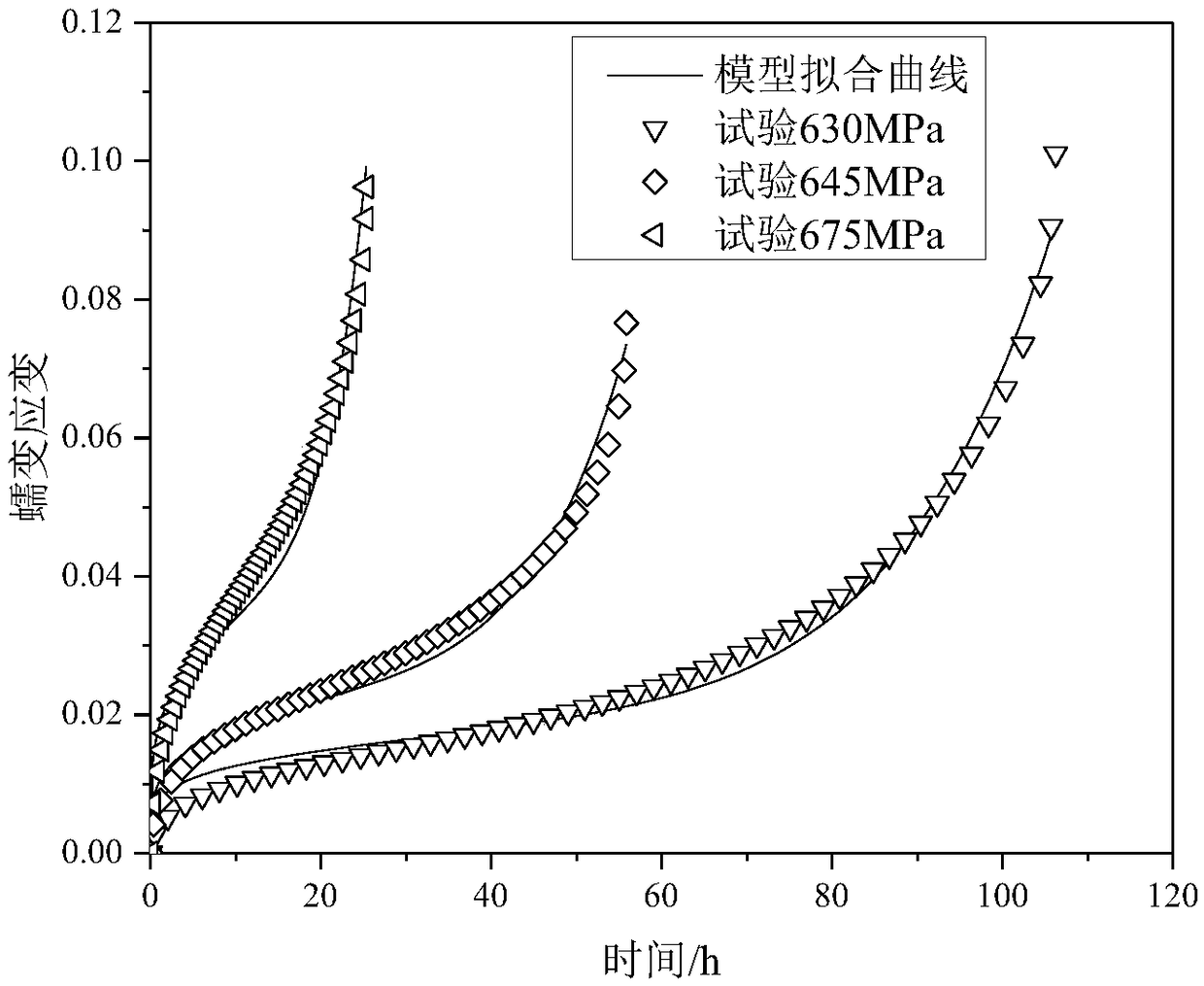

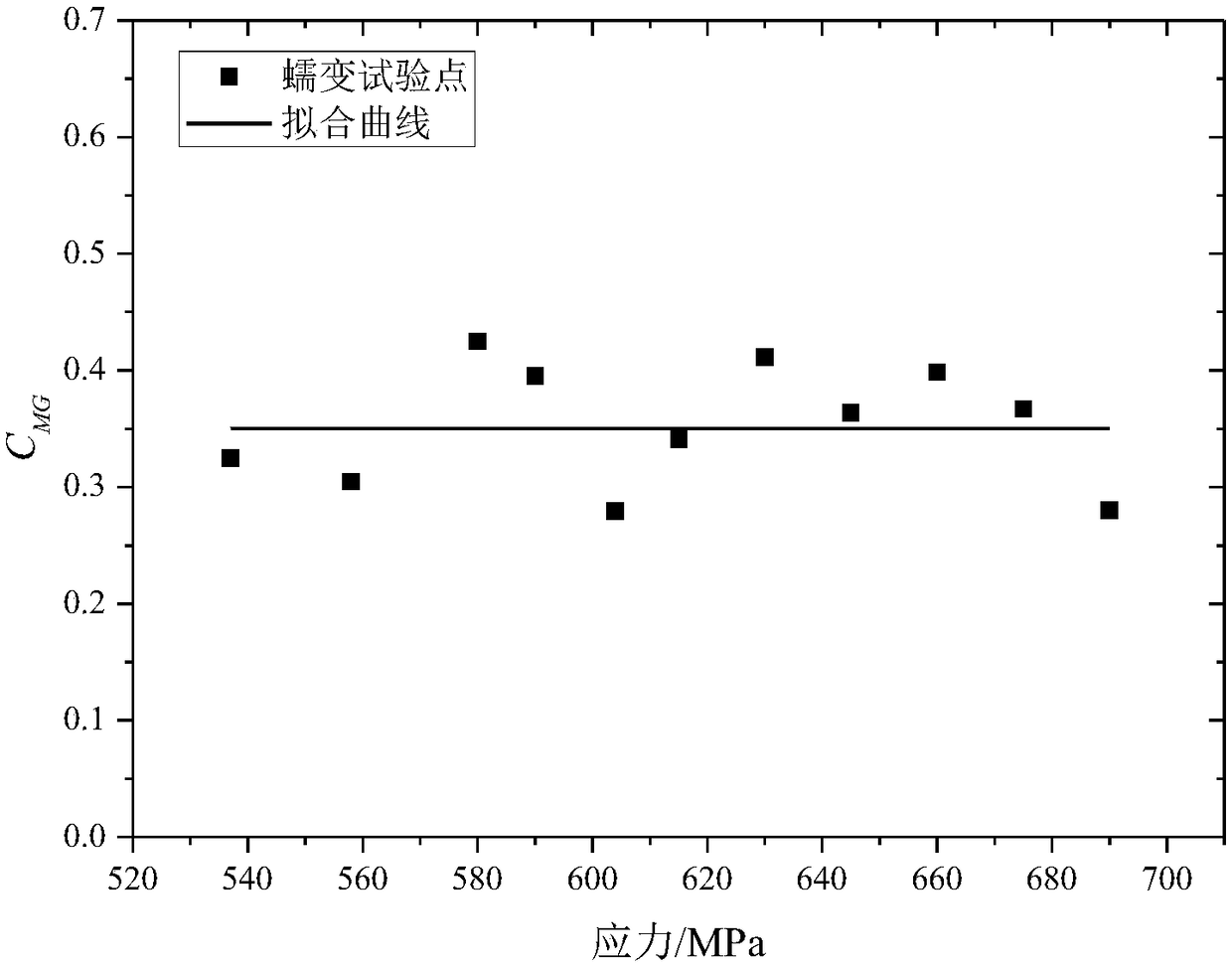

[0050] Step 1. According to the uniaxial creep test, the creep strain-time curve and the minimum creep rate of TC11 material under different stresses at 500°C are obtained creep strain at fracture and fracture life t f , as attached figure 2 , 3 shown; after obtaining the creep curve of the material, the minimum creep rate can be obtained by derivation

[0051] Step 2, select the appropriate creep constitutive equation, and obtain the creep constitutive parameters of TC11 material at 500°C through uniaxial creep test fitting, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com