Design method for reinforcing railway karst roadbed with high-strength geotextiles

A design method and technology of geotextiles, applied in calculation, instrumentation, geometric CAD, etc., can solve problems such as lack of theoretical basis and design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

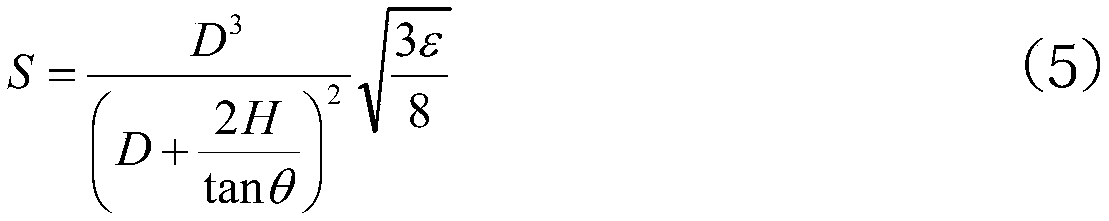

Method used

Image

Examples

Embodiment

[0041] 1. Design parameters

[0042] The outcropping strata of the XLK4+540~XLK4+660 section of a certain line are karst rocks of the Lower Triassic Anshun Formation (T1a), and surface surveys show karst phenomena such as karst ditches, troughs, karst depressions, and karst caves. Geophysical prospecting shows that the karst in this section is strongly developed, and it is mainly dissolved and broken zones, filled caves, and dissolved crevices. Drilling revealed the existence of karst caves with a maximum diameter of 1.6m. The left side of the line is the existing ballastless track passenger transport line, and the new project is a low-speed ballasted line, the filling height is 4-6m, and the filling weight is taken as kN / m 3 . If the grouting reinforcement has a great impact on the existing line, the track slab of the ballastless track may be lifted by the grouting pressure. Therefore, it is considered to use high-strength geotextile combined with surface water anti-seepage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com