An Improved Qualitative and Quantitative Analysis Method of Modified Polyacrylonitrile Fiber

A polyacrylonitrile, fiber qualitative technology, applied in the direction of analysis of materials, measuring devices, material weighing, etc., can solve the problems of flammability and toxicity of cyclohexanone, low efficiency, environmental pollution, etc., to improve employee efficiency and company market competition energy, save human resources, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Take the sample of modified polyacrylonitrile fiber and polyacrylonitrile fiber blend as an example:

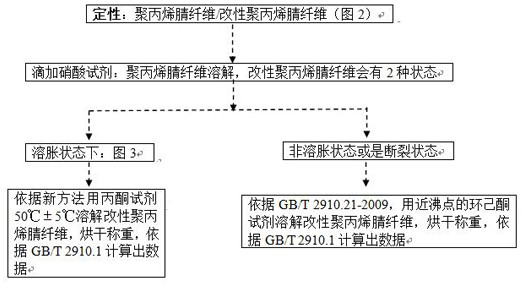

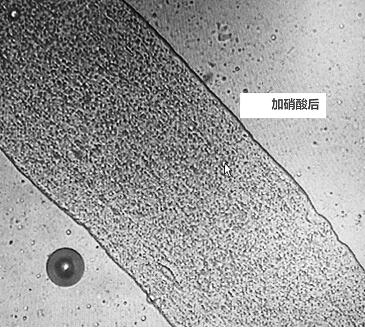

[0028] like figure 1 As shown, an improved qualitative and quantitative analysis method for modified polyacrylonitrile fiber, which includes the following process steps in turn: qualitative→sampling→drying and weighing→dissolving→drying and weighing→calculation, in the qualitative steps, including The process of adding nitric acid to the fiber. In this process, after the addition of nitric acid, if the fiber is judged to be fractured, cyclohexanone is used as a solvent in the subsequent dissolution step to dissolve it. If the fiber is judged to be swollen , then acetone is used as a solvent for dissolution in the subsequent dissolution step.

[0029] According to needs, there is also a pretreatment process between qualitative and sampling.

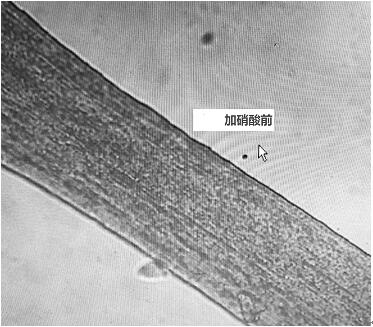

[0030] The specific process of the qualitative step is: the qualitative step is carried out according to FZ / T 01057.3-2007, spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com