Electrical machine rotor and commutator assembly tooling, assembly method and storage medium

A technology for motor rotors and assembly tooling, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as difficult control, press fit rate and low work efficiency, so as to reduce manufacturing costs and improve pressure. Assembly qualification rate and assembly efficiency, and the effect of ensuring installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

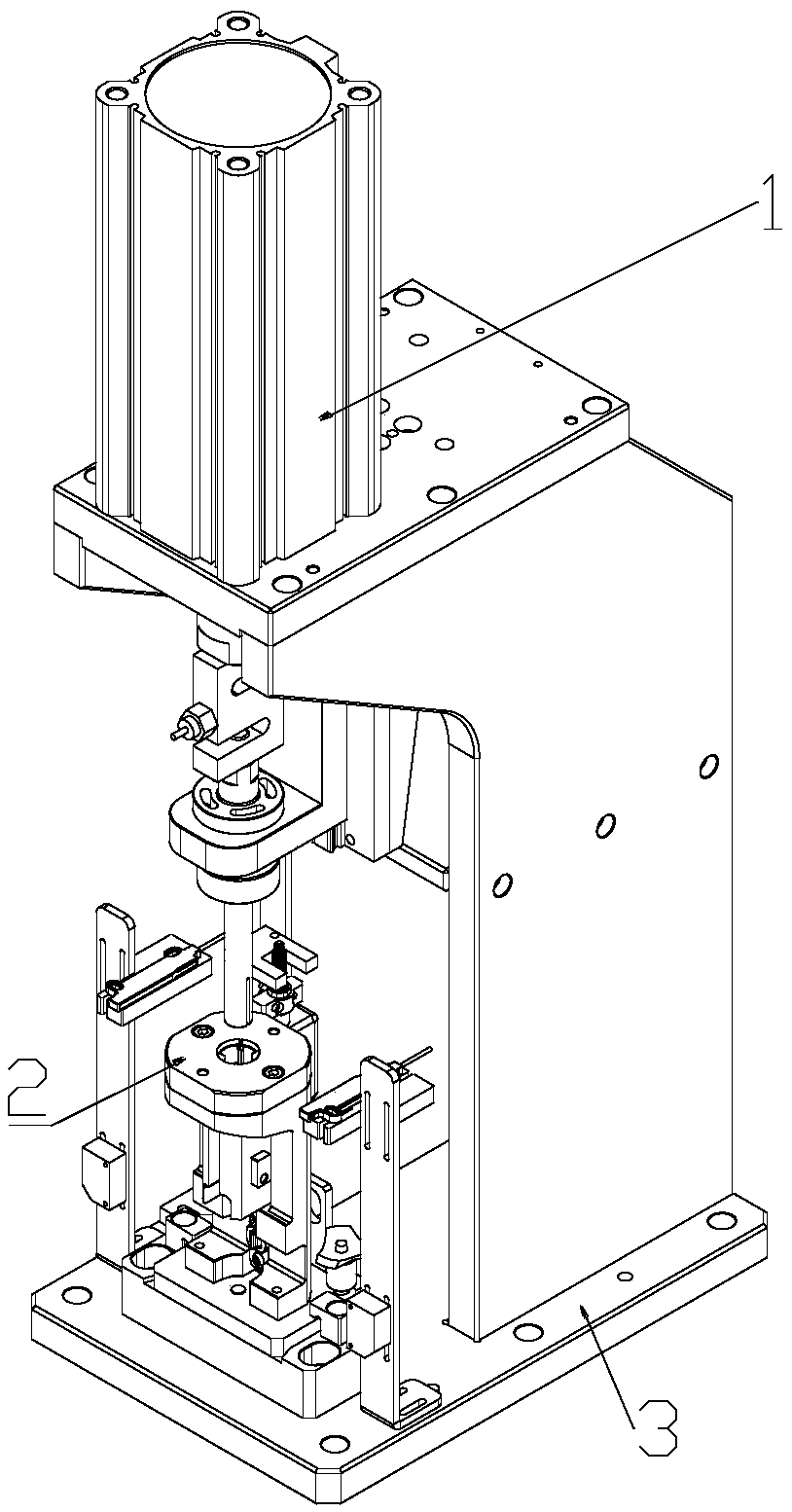

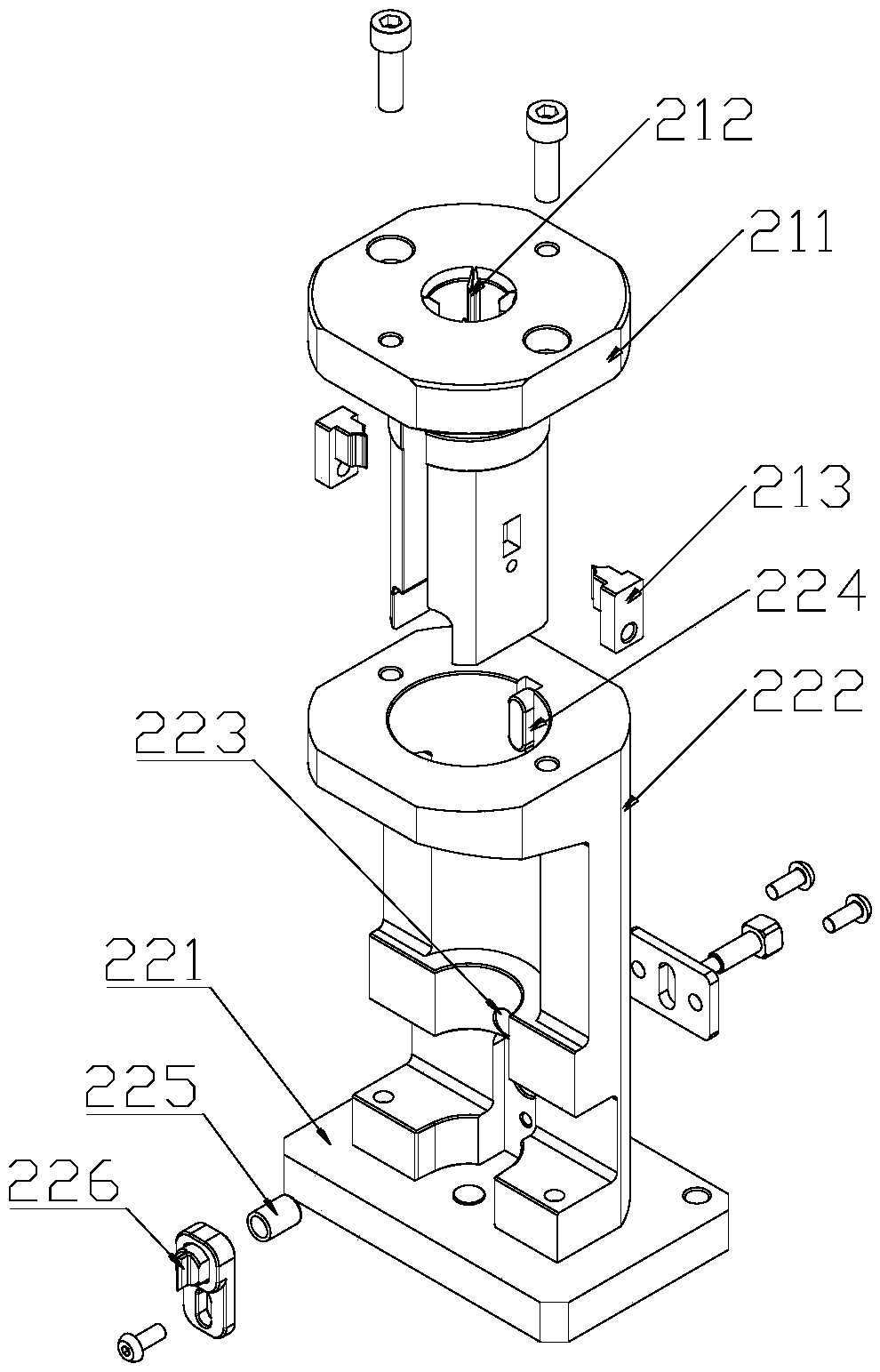

[0039] This embodiment provides a motor rotor and commutator assembly tooling, see figure 1 , the tooling includes a control system, a commutator press-in mechanism 1, a limit mechanism 2 and a support mechanism 3; where:

[0040] The control system includes a main controller and a plurality of detection devices connected to it, and the plurality of detection devices are respectively arranged in the commutator press-in mechanism 1, the limit mechanism 2 and the support mechanism 3, and are used to control the commutator The magnitude of the force, the installation position of the rotor and the commutator, and the press-fit operation of the motor rotor and the commutator are detected; the main controller controls the commutator press-in mechanism 1 according to each detection result;

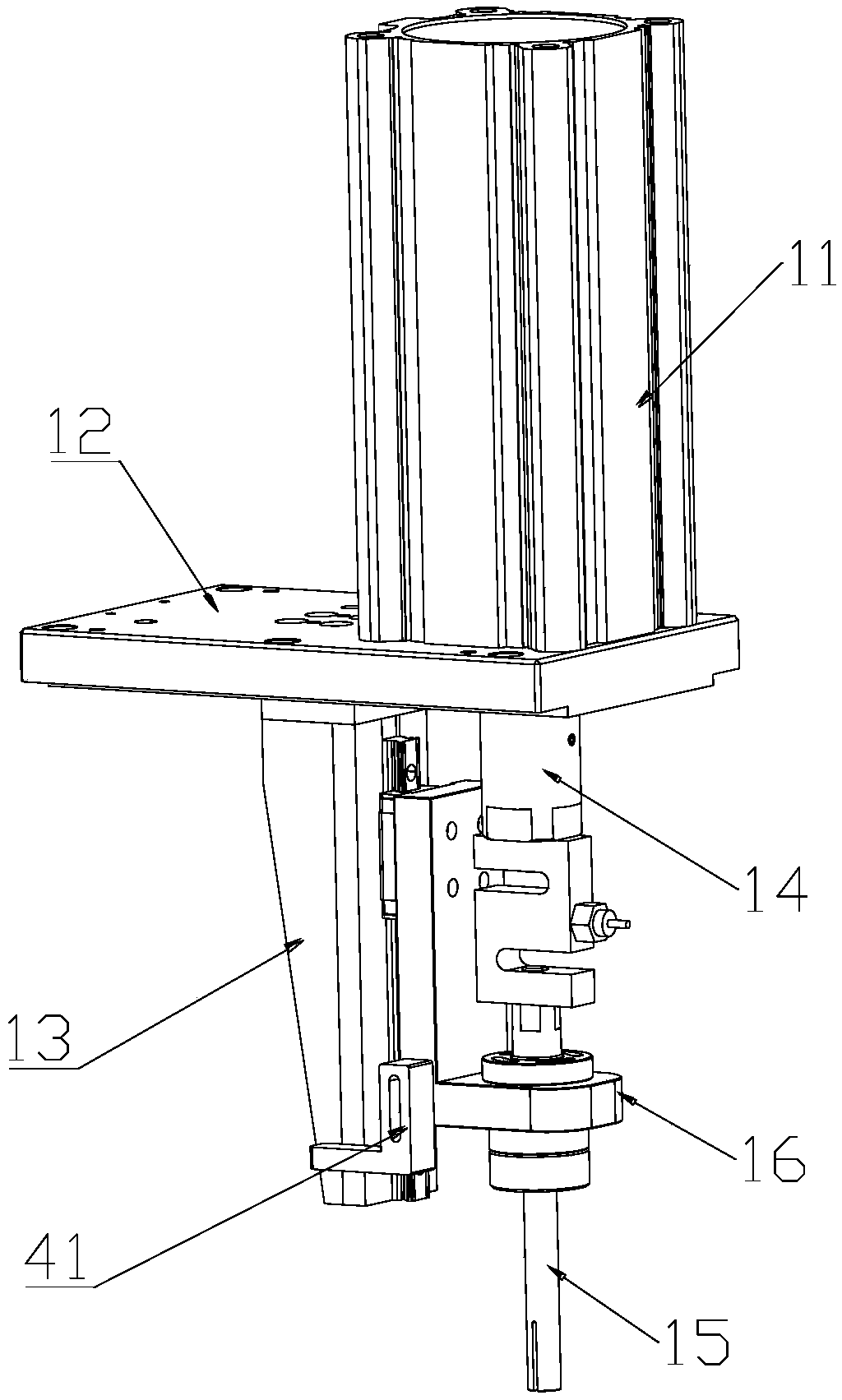

[0041] The commutator press-in mechanism 1 is arranged opposite to the limit mechanism 2, and includes a driving device and a commutator press-in device. device for press-fitting operation;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com