A heat dissipation strip of a PTC thermosensitive material heating device, a heating device and a special electric appliance

A technology for heating devices and heat-sensitive materials, applied in heating element materials, ohmic resistance heating parts, etc., can solve the problems of high manufacturing cost, easy de-soldering, poor welding, etc., to improve comfort and environmental protection functions, improve heat dissipation area, the effect of improving the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

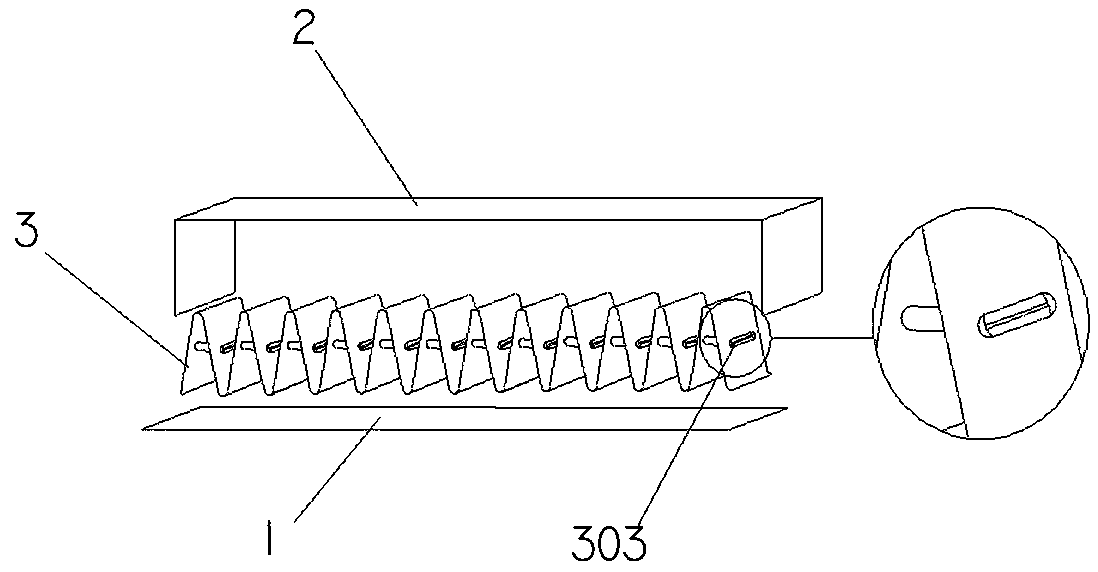

[0026] Such as figure 1 The heat dissipation strip of the PTC heat-sensitive material heating device shown includes a heat dissipation corrugation 3 clamped by a heat conduction flat sheet 1 and a folded edge positioning heat conduction sheet 2, and the heat dissipation corrugation has no less than one in the width direction of the heat dissipation surface. The concave arc surface 303 is parallel to the width direction of the heat radiation corrugations.

Embodiment 2

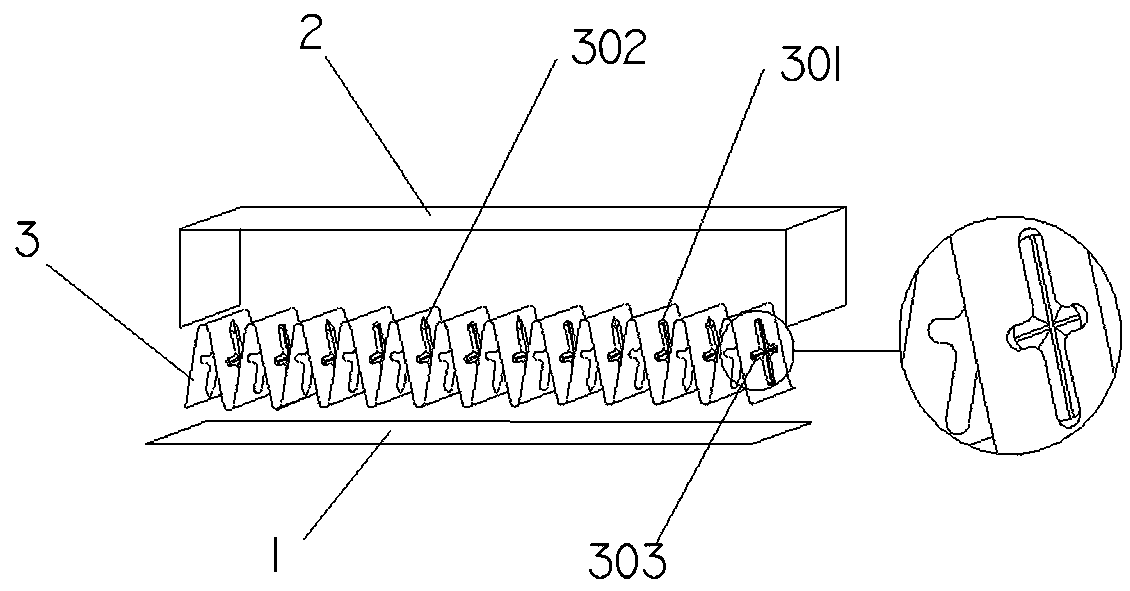

[0028] Such as figure 2 As shown, with reference to Embodiment 1, the height direction of the heat dissipation corrugation also has a concave surface 301, a folding fan surface 302 or a concave surface 301 and a folding fan surface 302, and the concave surface 301, an angled surface 302 or a concave surface 301 and a folding fan surface 302 is perpendicular to the width direction of the heat dissipation corrugations.

Embodiment 3

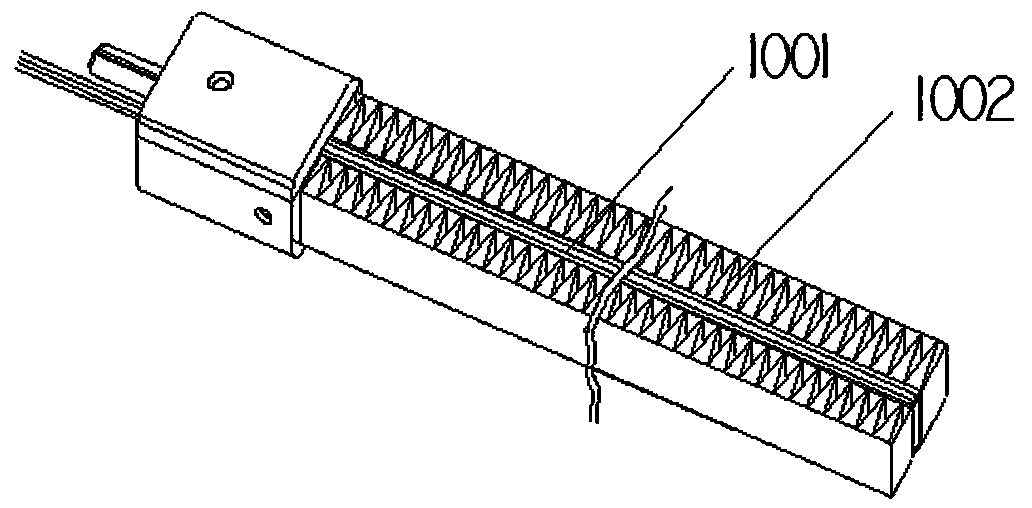

[0030] Such as image 3 The heating device of the PTC heat-sensitive material shown contains the heat dissipation strip described in the above-mentioned embodiment, including a PTC heating element, and the main component of the PTC heating element is Ba (1-x) PbxTiO3, the Ti is extracted from rutile TiO2 raw ore, and the molar ratio of Ti in the main component is greater than 1.00%; it also includes a PTC heating element, which is penetrated into a hollow heat-conducting aluminum tube by insulating After the heating core 1001 of the film-coated PTC thermal heating element is pasted in parallel between the two electrode sheets, the heat-conducting surface of the aluminum tube is pressed to eliminate the gap between the heating core in the heating body and the inner wall of the aluminum tube. A surface-insulated PTC heating element is formed, and the PTC heat-sensitive material heating element is formed after the heat-conducting surface of the aluminum tube of the heating elemen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap