Plug-and-pull module and frame type equipment

A technology of body and elastic parts, applied in the field of plug-in modules and frame-type equipment, which can solve the problems of reducing heat dissipation effect, small slot wind resistance, and reduced cooling air volume of frame-type equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

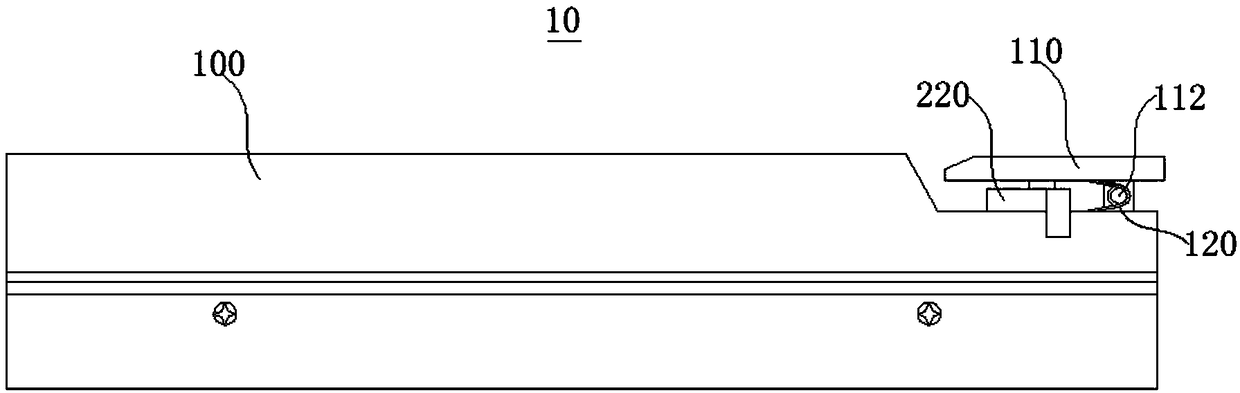

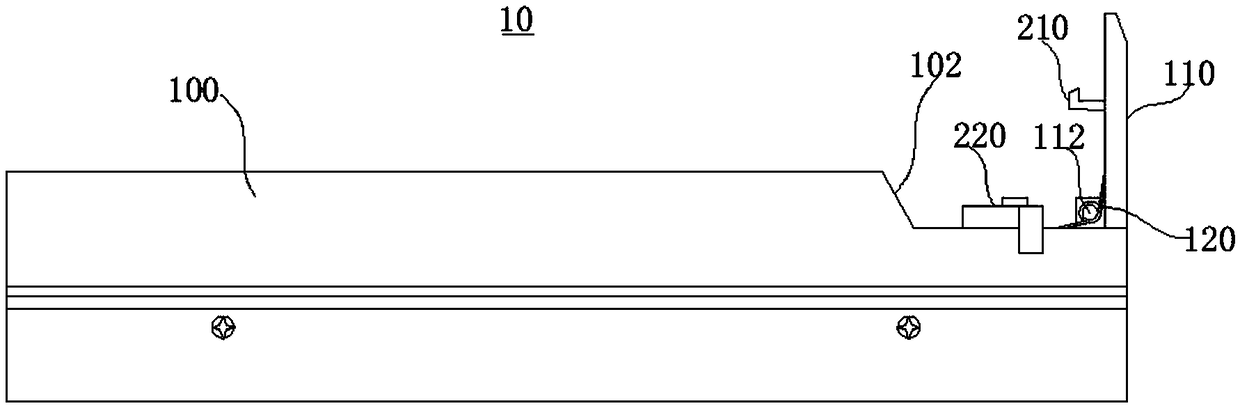

[0031] Please refer to figure 1 and figure 2 , the present embodiment provides a plug-in module 10 for plugging and matching with one of the slots of the chassis. In detail, the plug-in module 10 may be a pluggable module on a frame-type device such as a single-board module, a fan module, and a power supply module.

[0032] The plug-in module 10 includes a module body 100 , a turning member 110 and a first elastic member 120 . The turning member 110 is rotatably mounted on the module body 100 . The first elastic member 120 is disposed between the module body 100 and the turning member 110 . When the flipper 110 is in the first position, the flipper 110 is adjacent to the surface of the module body 100; when the flipper 110 moves from the first position to the second position under the action of the first elastic member 120, the flipper 110 is covered and inserted The slot where the module 10 is located is adjacent to the slot.

[0033] Wherein, the module body 100 is rough...

no. 2 example

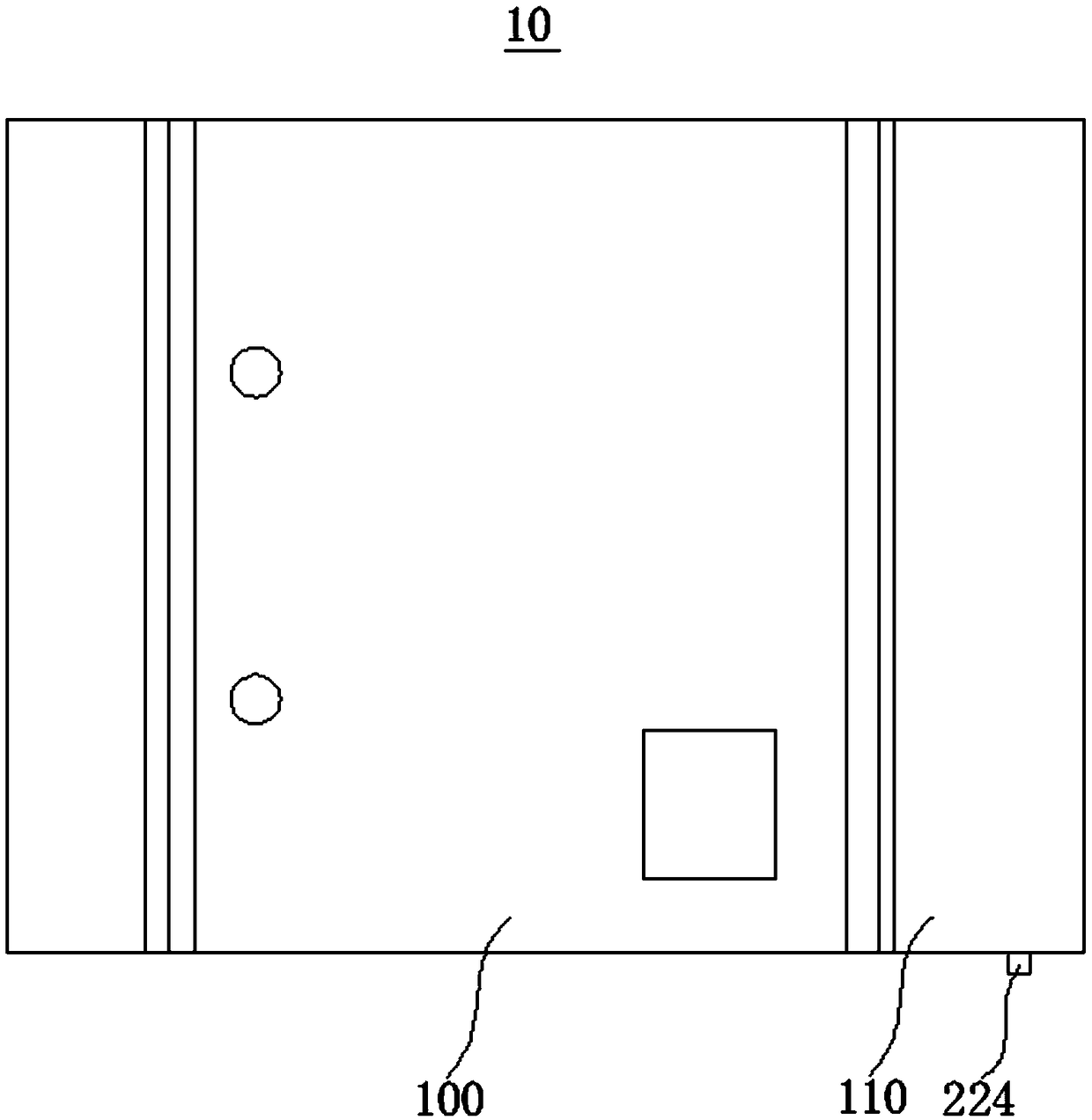

[0049] Please refer to Figure 5 This embodiment provides a plug-in module 10 whose overall structure, working principle and technical effects are basically the same as the plug-in module 10 provided in the first embodiment, except for the specific structure of the locking assembly 200 .

[0050] In this embodiment, the locking assembly 200 includes a second locking hook 212 disposed on the turning member 110 , a sliding member 240 disposed on the module body 100 , and a third elastic member 250 disposed between the module body 100 and the sliding member 240 , the sliding member 240 holds the second locking hook 212 under the action of the third elastic member 250 .

[0051] The slider 240 is roughly elongated and includes a sliding part 242 and a second trigger part 244 connected to each other. When the plug-in module 10 is inserted into the slot and the second trigger part 244 touches a predetermined position of the chassis, the second trigger part 244 The sliding part 242 ...

no. 3 example

[0054] Please refer to Figure 6 , this embodiment provides a frame-type device 20, which includes a chassis 22 and the plug-in module 10 provided in the first embodiment or the second embodiment, the chassis 22 is provided with a plurality of slots 24, and the plug-in module 10 is plugged into in one of the slots 24. The turning part 110 of the plug-in module 10 is in the second position, so as to cover the slot 24 adjacent to the slot 24 where the plug-in module 10 is located. The frame-type device 20 has the characteristics of high heat dissipation efficiency, which effectively makes up for the defects of the existing frame-type devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com