Pump Can Kits for Beverage Cans

A technology of beverage cans and pump cans, which is applied in the field of pump can sets, and can solve the problems that functional correlation cannot be simply converted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

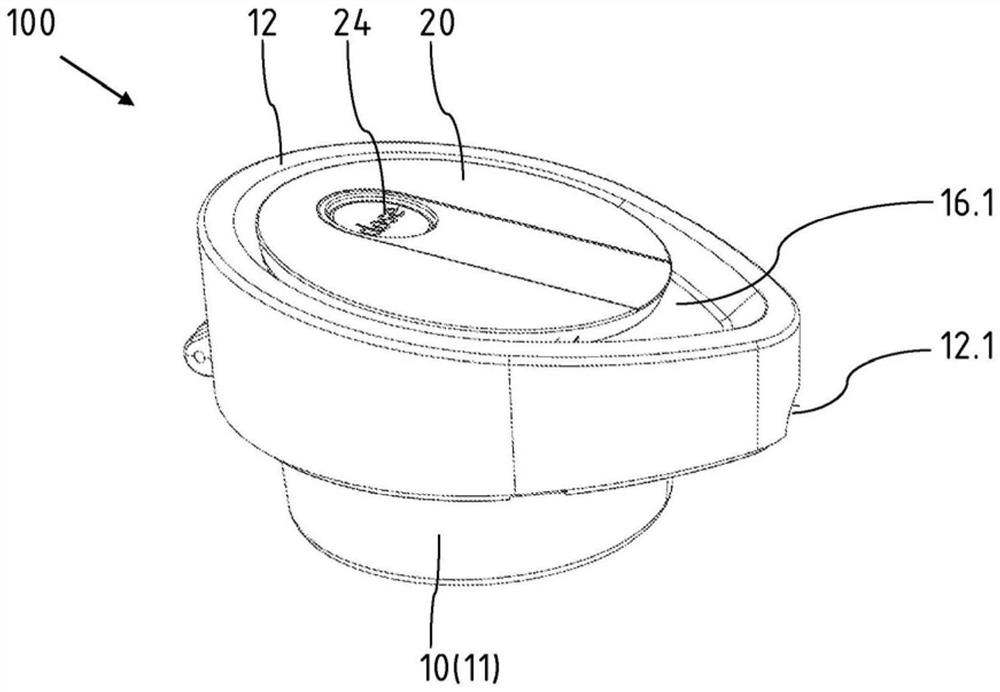

[0022] figure 1 The pump canister set 100 is shown from the outside in a perspective view. The housing 10 has, in addition to the housing upper part 12 , a lower part 11 which is slightly reduced in diameter. The housing upper part 12 is designed to be slightly lowered to the right—thus where the discharge pipe of the riser unit (not shown) cooperating with the pump tank set 100 is arranged. Overall, a flat and aesthetically appealing configuration of the pump canister set 100 is achieved.

[0023] exist figure 1 In the region on the right in , at the bottom, a cutout 12 . 1 can be seen on the overhang of the housing upper part 12 , which accommodates the outlet pipe. A recess 16 . Finished evenly. The button 24 can be actuated via a cutout in the pump lever 20 .

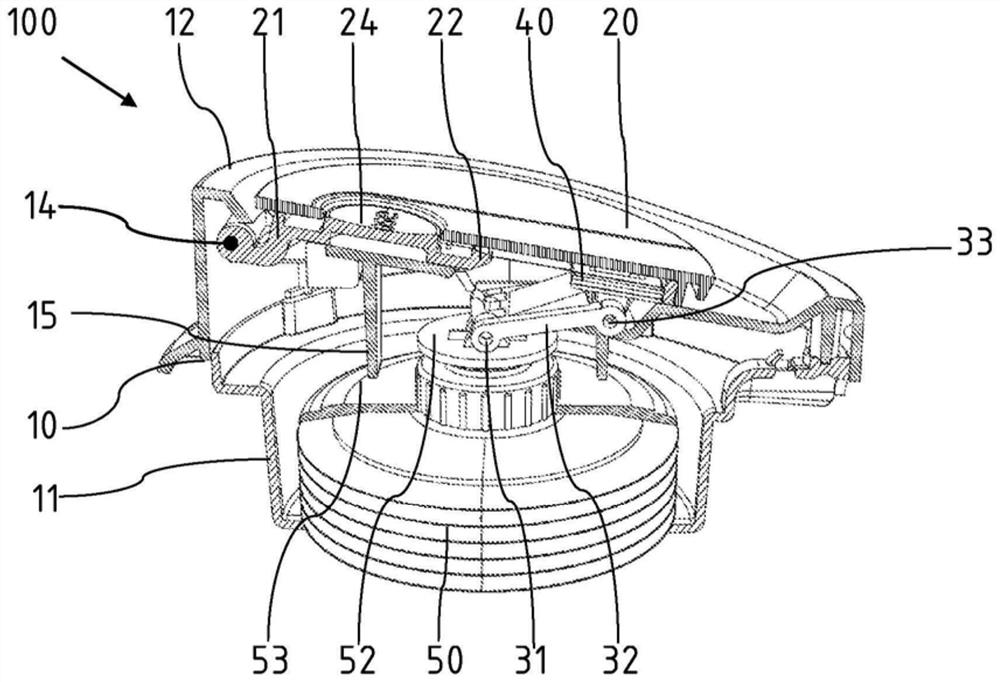

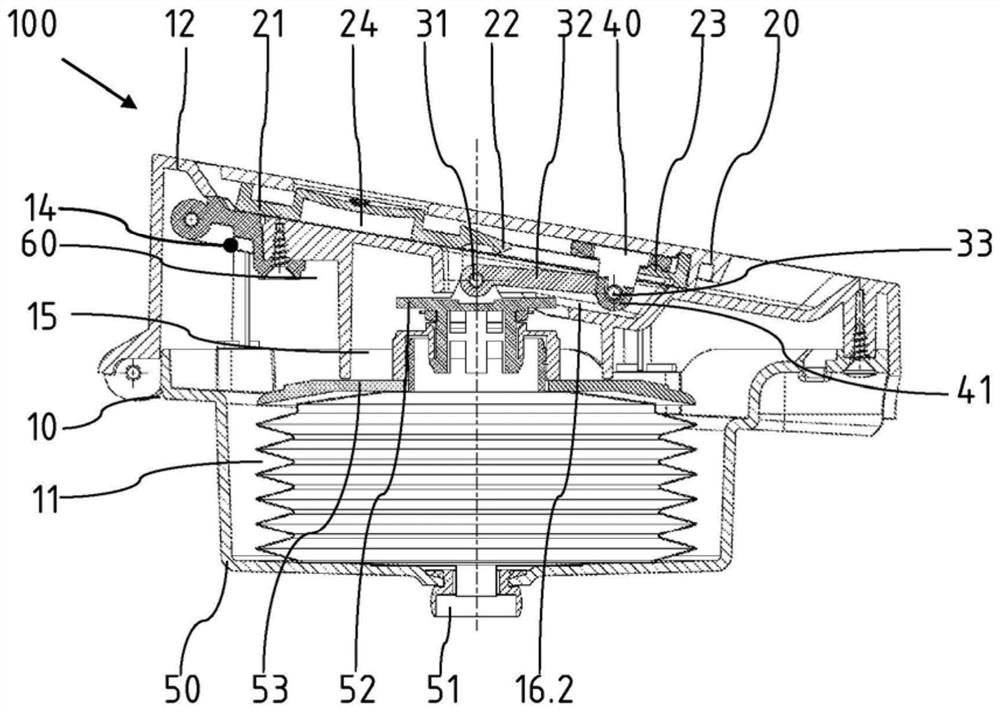

[0024] figure 2 The pump tank set 100 is likewise shown in perspective and in the transport position, wherein all components are shown in cross-section except for the pump assembly including the pump bellows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com