Waste gas treatment device

An exhaust gas treatment device and exhaust gas technology, applied in the direction of gas treatment, dispersed particle filtration, membrane technology, etc., can solve problems such as time delay, monotonous structure, troublesome replacement, etc., and achieve no need for replacement and cleaning, high working efficiency, and wide contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

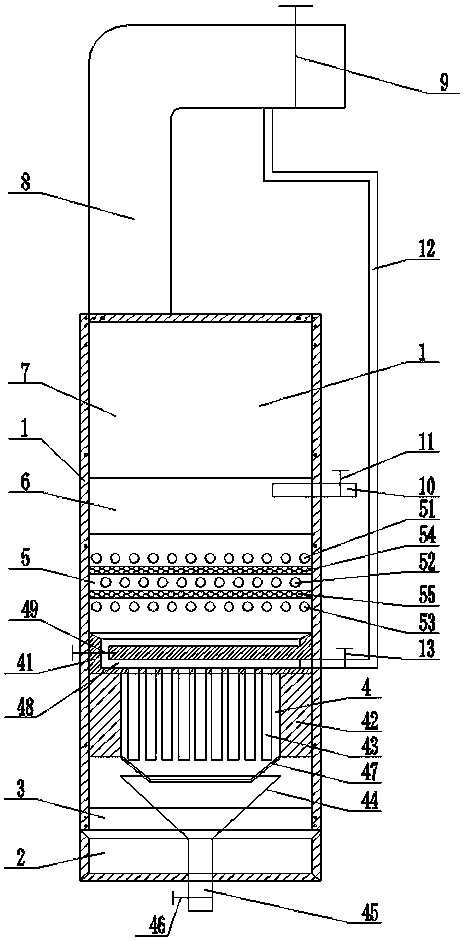

[0009] Such as figure 1 As shown, the exhaust gas treatment device includes: a box body 1, an exhaust gas air inlet 2 is arranged at the lower end of the box body 1, and an ozone filter cotton layer 3 is arranged in the box body 1 at the upper end of the exhaust gas air inlet 2. The box body 1 at the upper end of the ozone filter cotton layer 3 is provided with a dust filter device 4, the structure of the dust filter device 4 includes: a beam 41 arranged on the box body 1, and a box body 1 at the lower end of the beam 41 An annular column 42 is arranged on the inner wall, and a plurality of dust-removing bags 43 are evenly arranged on the beam 41 inside the annular column 42, and an ash hopper 44 is arranged in the box body 1 at the lower end of the dust-removing bag 43. 44 extends into the lower end of the ozone filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com