Mold for blow molding of air filter pipe and insert of mold

A technology for air filter tubes and molds, which is applied in the field of blow molding, can solve the problems of high manufacturing cost of air filter tubes, easy deformation of air filter tubes, and high equipment costs, and achieve the goals of reducing production costs, good stability, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

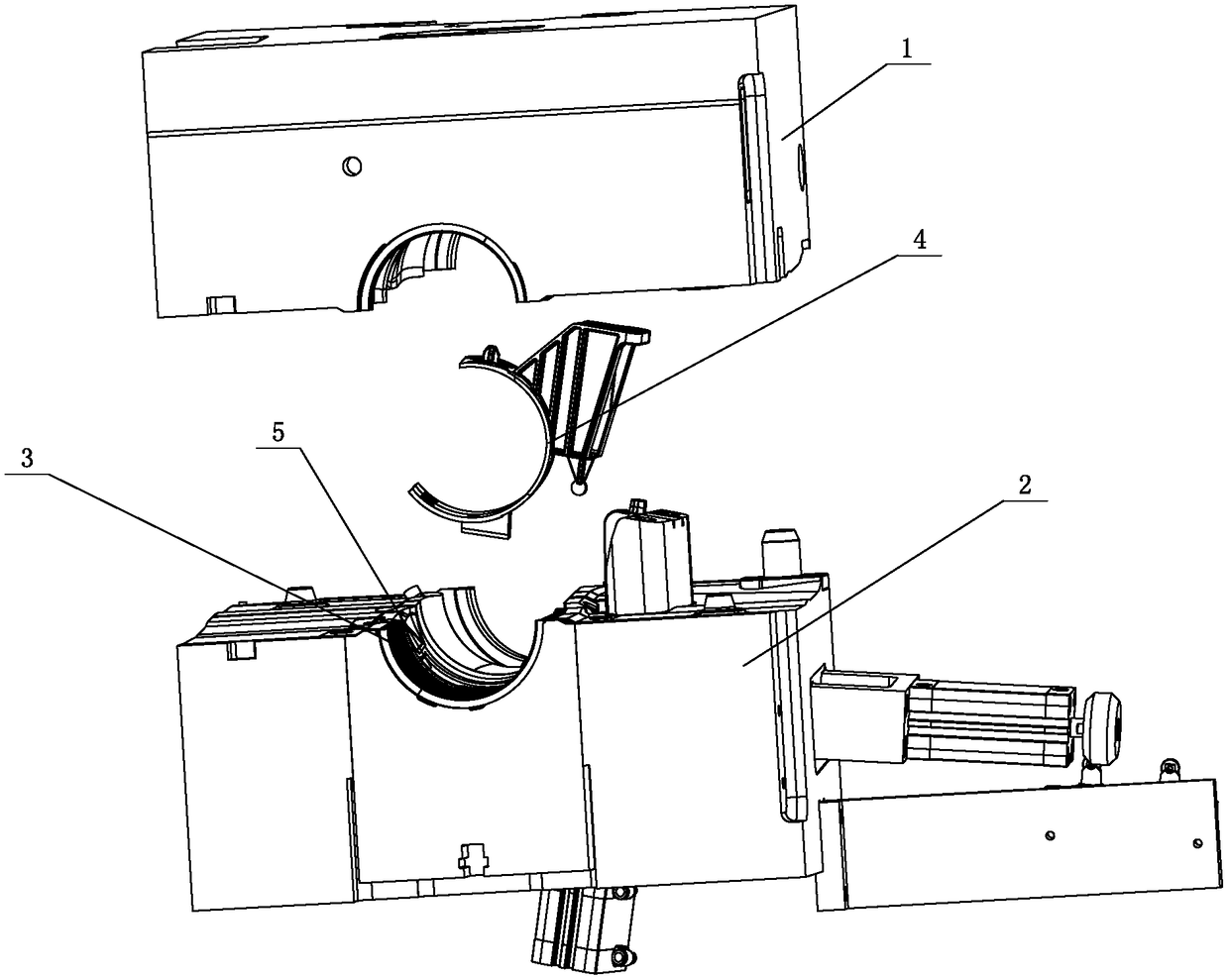

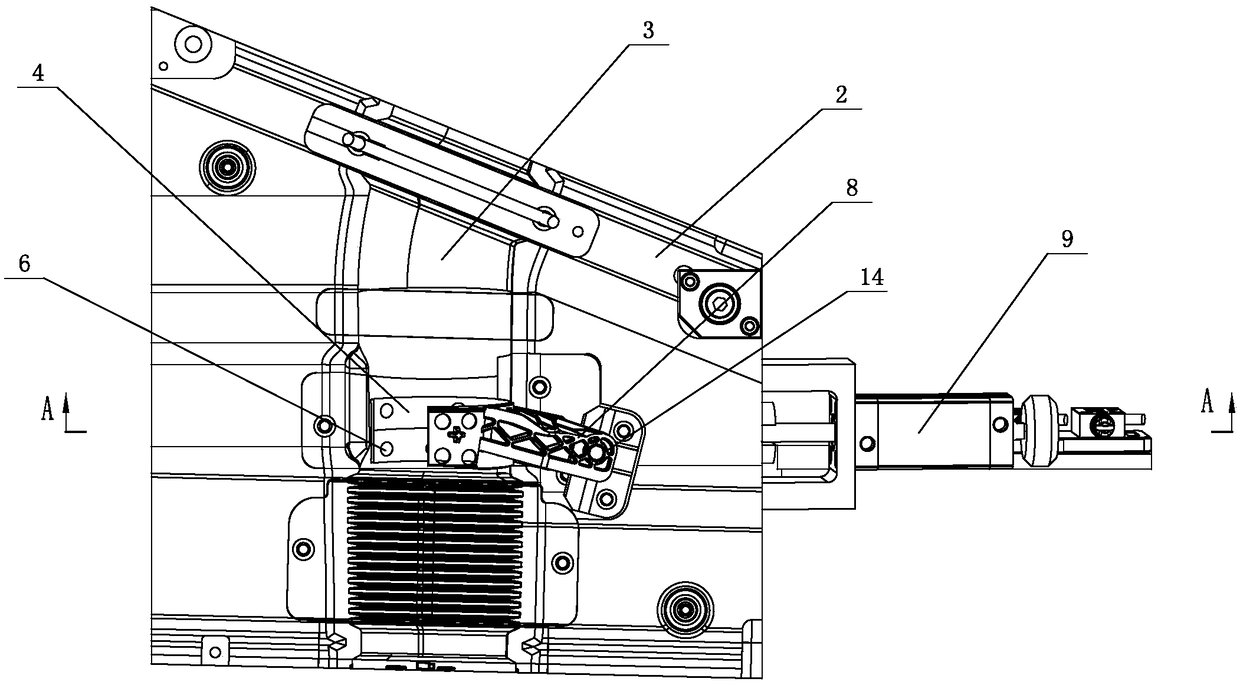

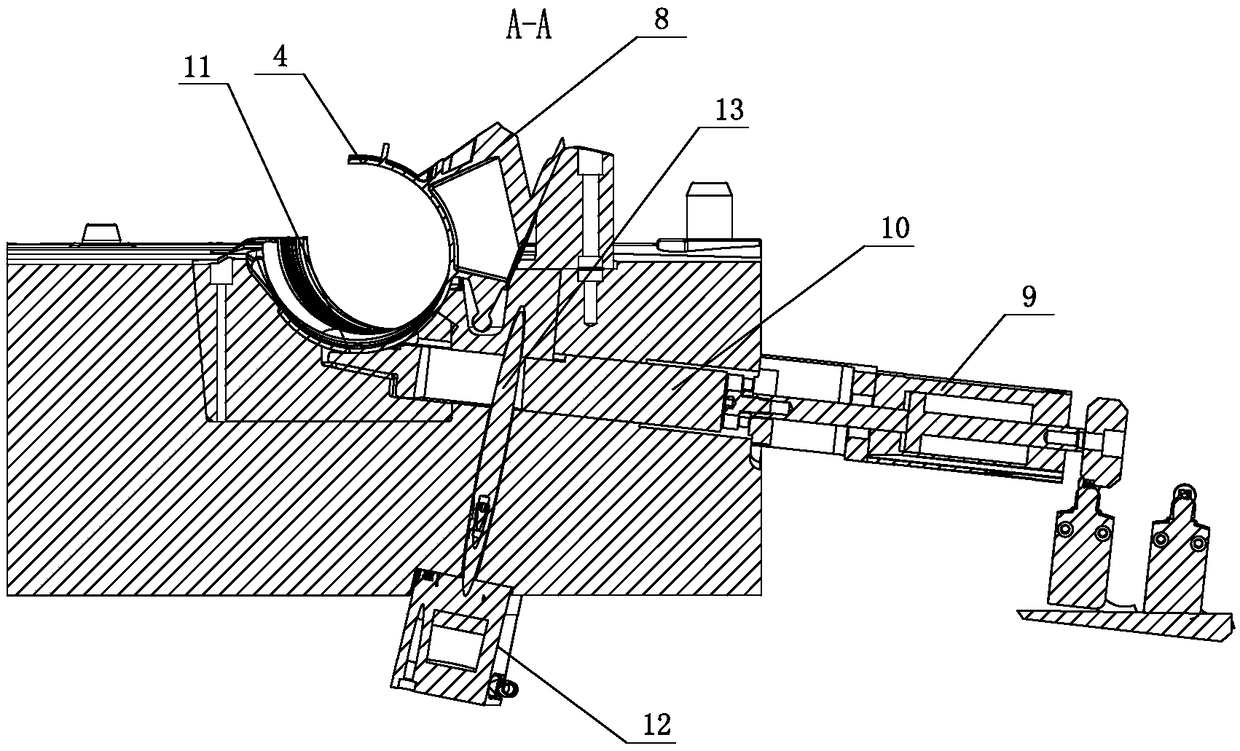

[0027] combine Figure 1~5 , a mold for air filter pipe blow molding, it wraps upper mold 1 and lower mold 2, said upper mold 1 is provided with a first inner concave, lower mold 2 is provided with a second inner concave 3, between upper mold 1 and lower mold When the molds 2 are merged, the first indentation and the second indentation 3 form an empty filter tube cavity, and a connector 4 is embedded in the cavity of the air filter tube, and the first indentation is provided with a first cavity for accommodating the upper part of the connector 4. A groove, the second recess 3 is provided with a second groove 5 for accommodating the lower part of the connector 4, the first groove and the second groove 5 form a space for accommodating the connector 4; the lower mold 2 is provided with A positioning mechanism for positioning the connecting piece 4.

[0028] Connector 4 is provided with at least four connecting holes 6 (eight in this example, also can be four, five, six or ten et...

Embodiment 2

[0037] A mold for air filter pipe blow molding, which includes an upper mold 1 and a lower mold 2, the upper mold 1 is provided with a first concave, the lower mold 2 is provided with a second concave 3, and the upper mold 1 and the lower mold 2 are combined , the first indentation and the second indentation 3 form an air filter tube cavity, and a connector 4 is embedded in the cavity of the air filter tube, and a first groove for accommodating the upper part of the connector 4 is provided on the first indentation , The second concave 3 is provided with a second groove 5 for accommodating the lower part of the connector 4; the lower mold 2 is provided with a positioning mechanism for positioning the connector 4.

[0038] The connecting piece 4 is provided with at least four connecting holes 6 (seven in this example, and can also be four, five, six or ten, etc.), and the connecting holes 6 are distributed at the positions near both ends of the connecting piece 4 .

[0039] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com