Syringe printing positioning mechanism

A positioning mechanism and syringe technology, applied in printing presses, rotary printing presses, printing and other directions, can solve the problems of inability to make individual adjustments, inconsistent product zero lines, etc., to ensure printing accuracy, improve smoothness and non-stickiness, Guarantee the effect of printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

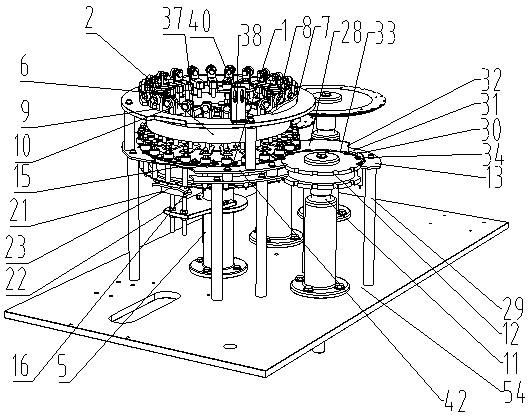

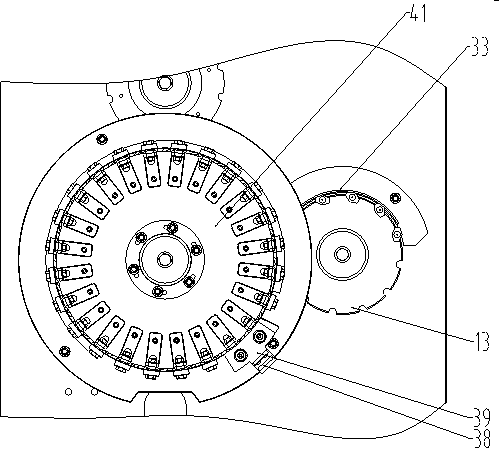

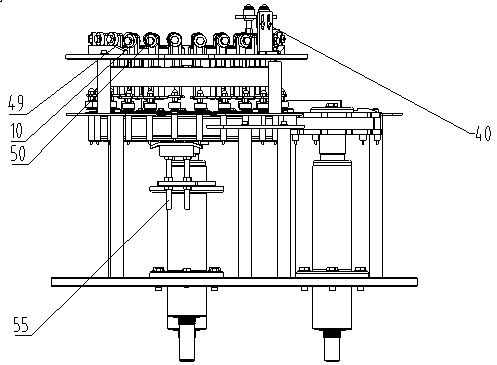

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, a syringe printing positioning mechanism provided by the present invention includes: a positioning assembly 1, a pressing and fixing device 2 and a feeding device 3; the pressing and fixing device includes a fixing assembly 4, a printing shaft 5 and a Printing assembly 6, the top of the fixed assembly has an arc-shaped guide plate 7 arranged along the circumferential direction of the printing shaft, and the two ends of the guide plate have slopes 8 inclined from the top of the guide plate to the top plate and bottom plate; the printing assembly includes connecting 9, the top of the connecting piece is equipped with a roller 10, the roller moves along the top surface of the guide plate, and is used to drive the printing assembly to move up and down.

[0036] The feeding device comprises a feed shaft 11 and a feed tray 12 installed on the top of the feed shaft, and a feed fixed disc 13 is install...

Embodiment 2

[0046] A positioning assembly, the positioning assembly includes an upper chuck; a plurality of circumferentially arranged positioning blocks are installed on the upper end surface of the upper chuck, and the positioning blocks are fixed on the upper chuck by detachable positioning fasteners; The side surface of the outer end of the positioning block has an inward depression to form a positioning groove, and the positioning groove is adapted to the outer surface of the handle of the syringe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com