High-speed arrangement production line

A production line, high-speed technology, applied in the field of finishing equipment for small packaging bags, can solve the problems of low packaging efficiency, easy overturning, and inability to stack vertically into a stack, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

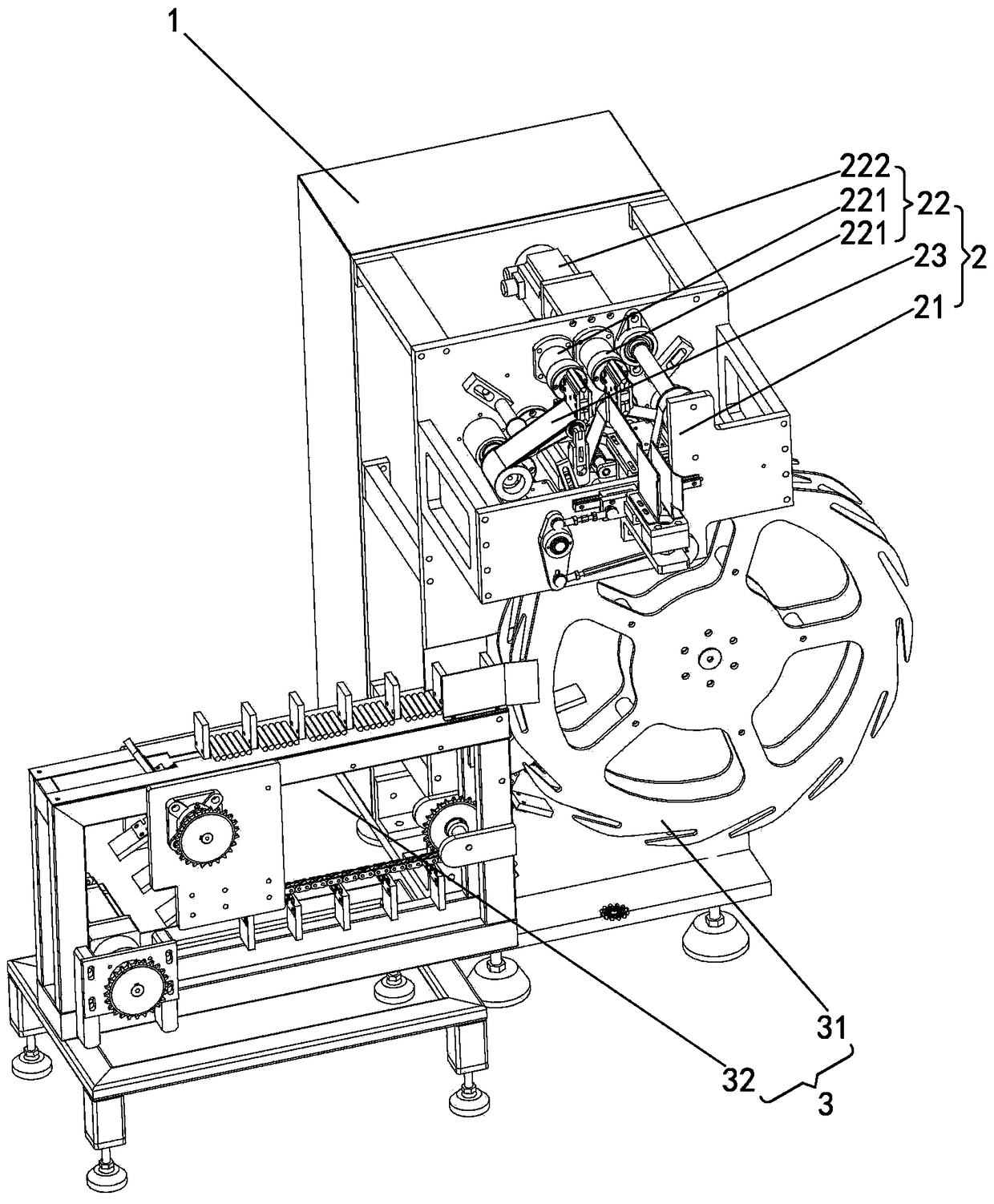

[0025] Such as Figure 1-5 As shown, the high-speed sorting production line in this preferred embodiment includes a frame 1, and the small packaging bag alternate bag dropping mechanism 2, which can separate the small packaging bags alternately and quickly vertically drop the bags, is installed on the frame 1. The bag unscrambling mechanism 3 that can quickly organize and transfer the small packaging bags in sequence, the alternate bag dropping mechanism 2 of the small packaging bags is located above the bag sorting mechanism 3, the outlet of the small packaging bags alternate bag dropping mechanism 2 and the entrance of the bag sorting mechanism 3 connected.

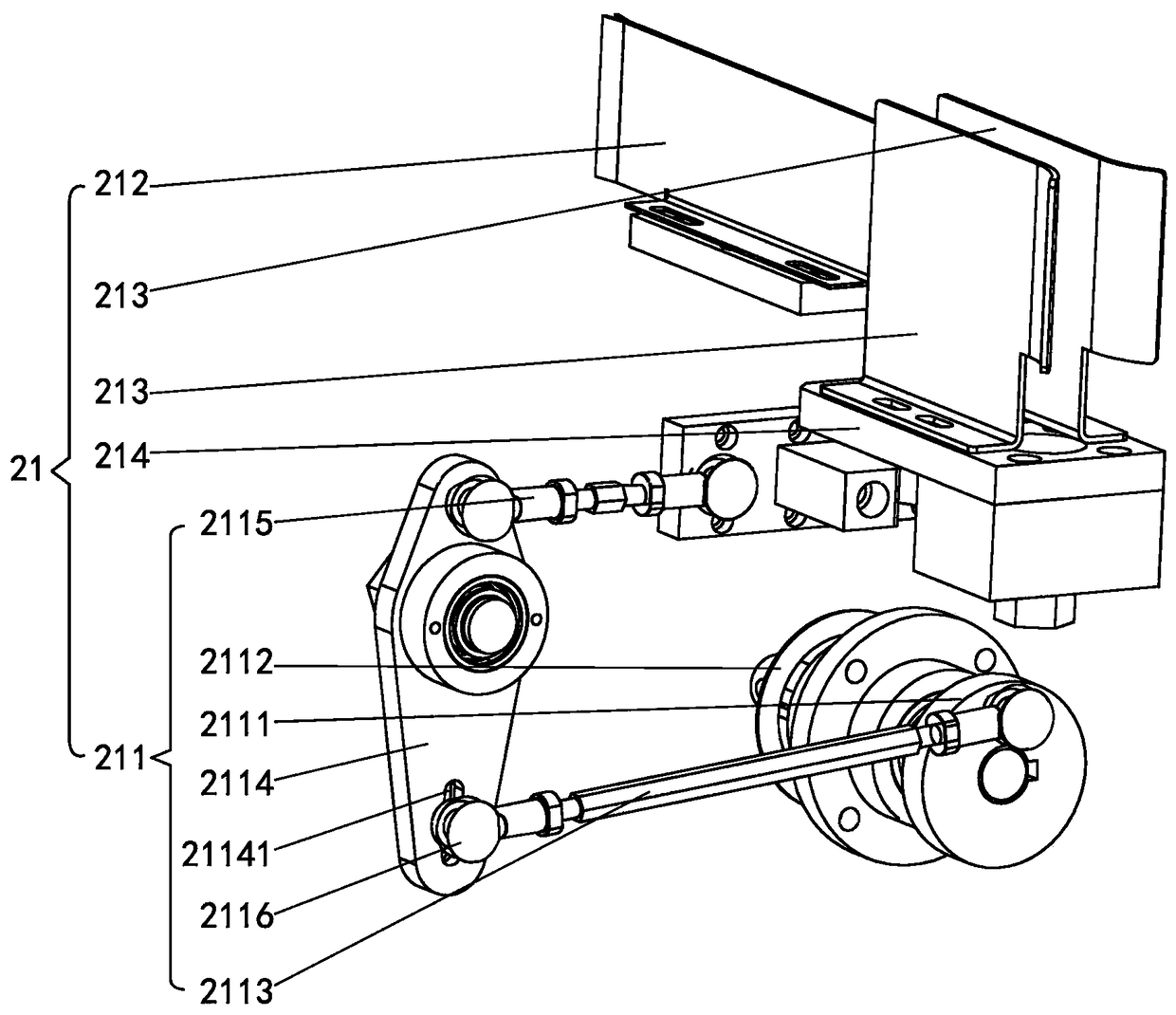

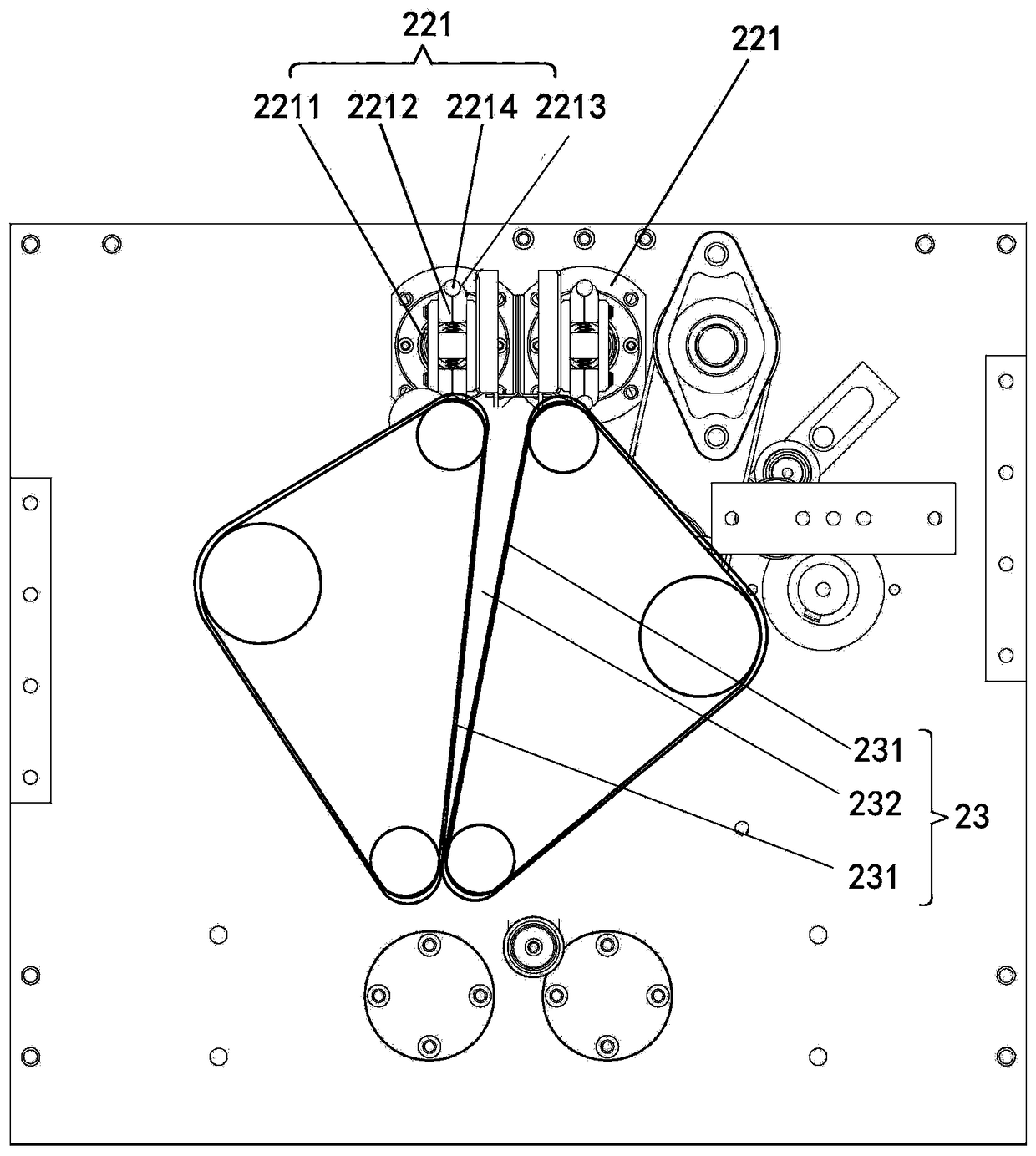

[0026] The small packaging bag alternate bag dropping mechanism 2 includes a fast alternate distribution unit 21, a bag removal unit 22, and a fast bag drop unit 23. The fast alternate distribution unit 21 includes a swing mechanism 211, a partition plate 212, a swing seat 214, two Block distribution piece 213, describ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap