Double base close type triangular hoisting device for energy-saving prefabricated member and application method

A lifting device and triangular lifting technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of severe wear at the junction of nylon lifting belts, easy falling of extra-heavy energy-saving prefabricated parts, and violent vibration of energy-saving prefabricated parts. , to achieve the effect of avoiding frequent sliding, improving service life and increasing contact length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

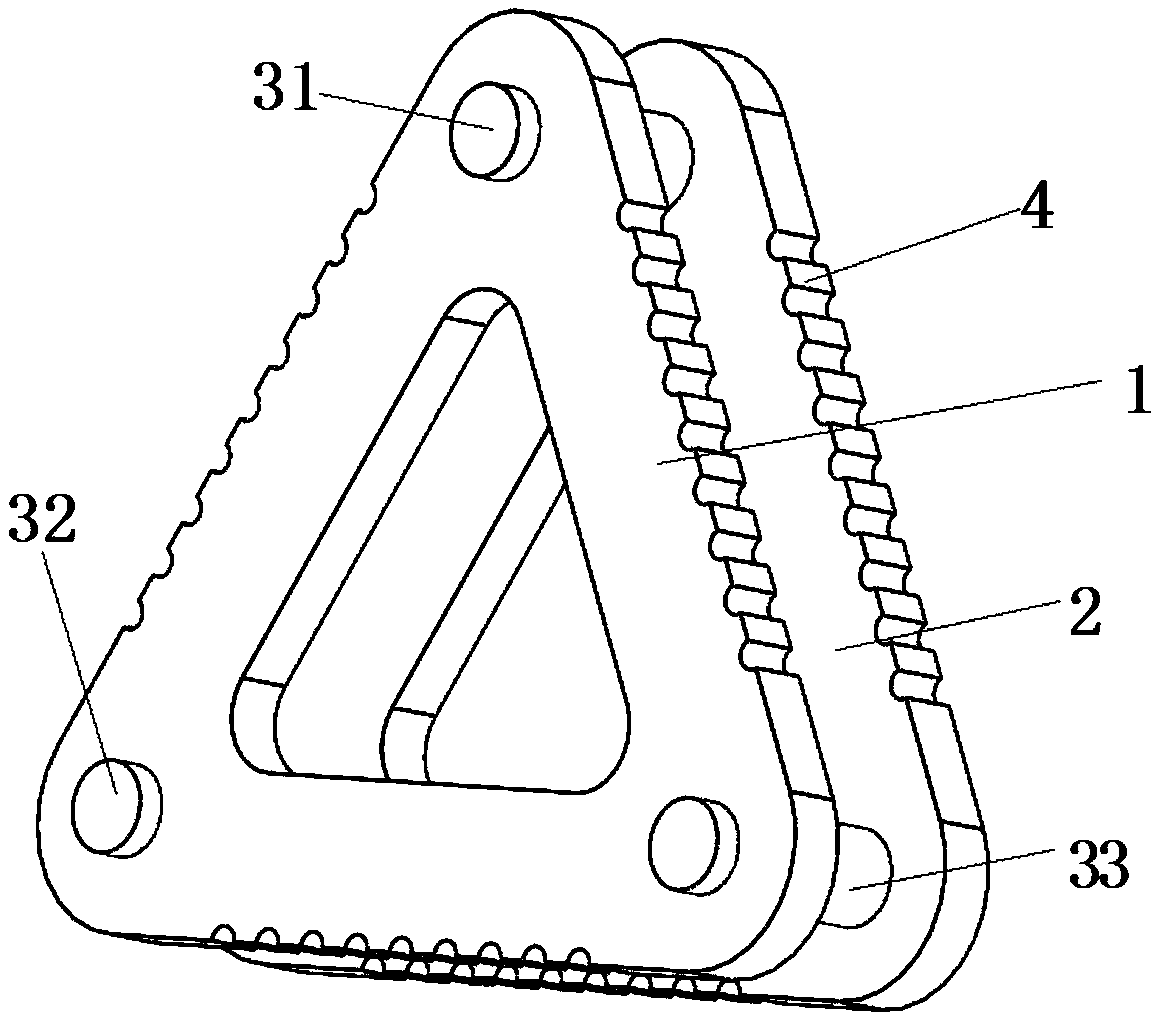

[0050] According to specific embodiments of the present invention, such as Figure 1-Figure 7 Shown is the double-base enclosed triangular lifting device for energy-saving preforms of the present invention, including:

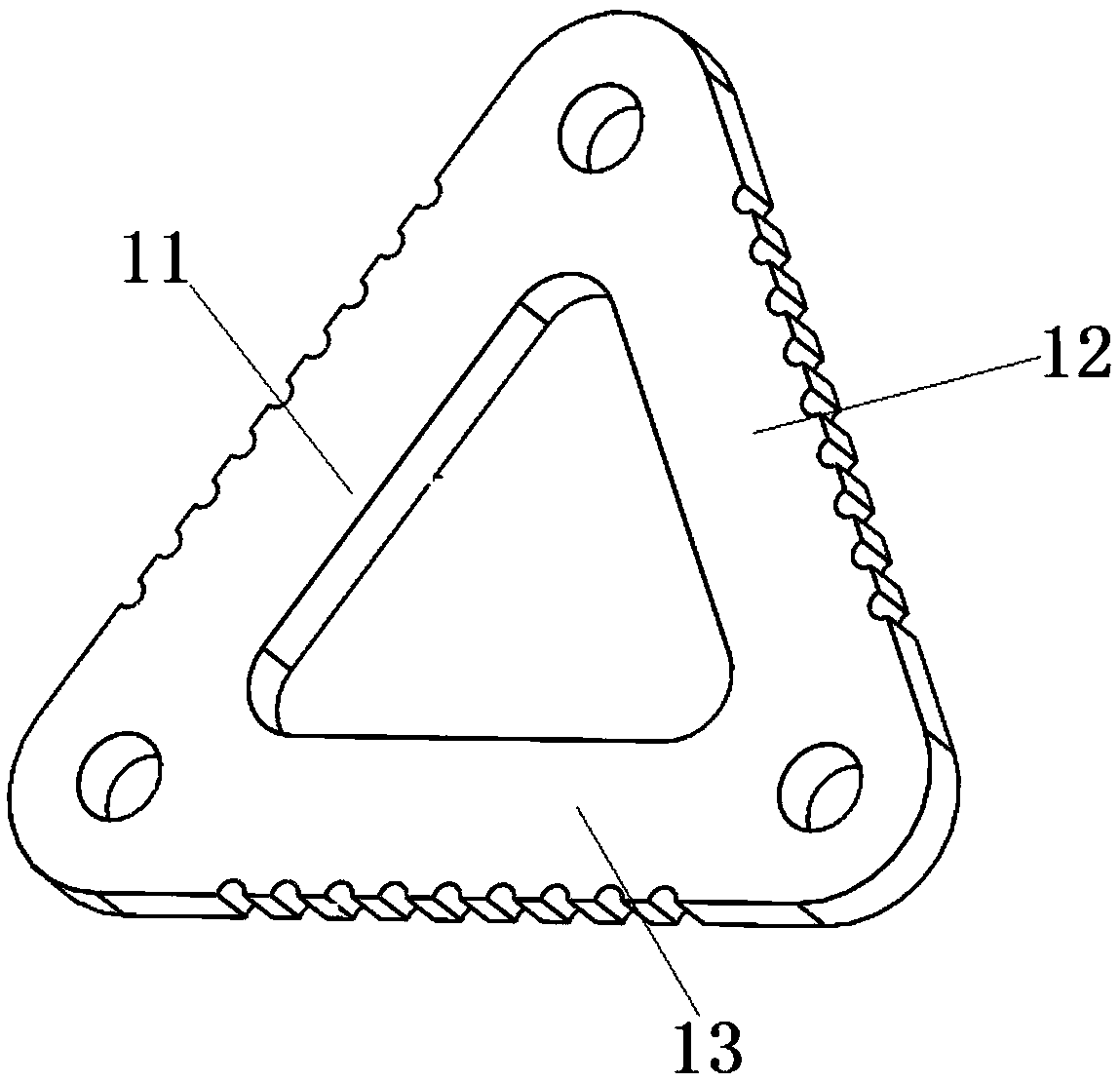

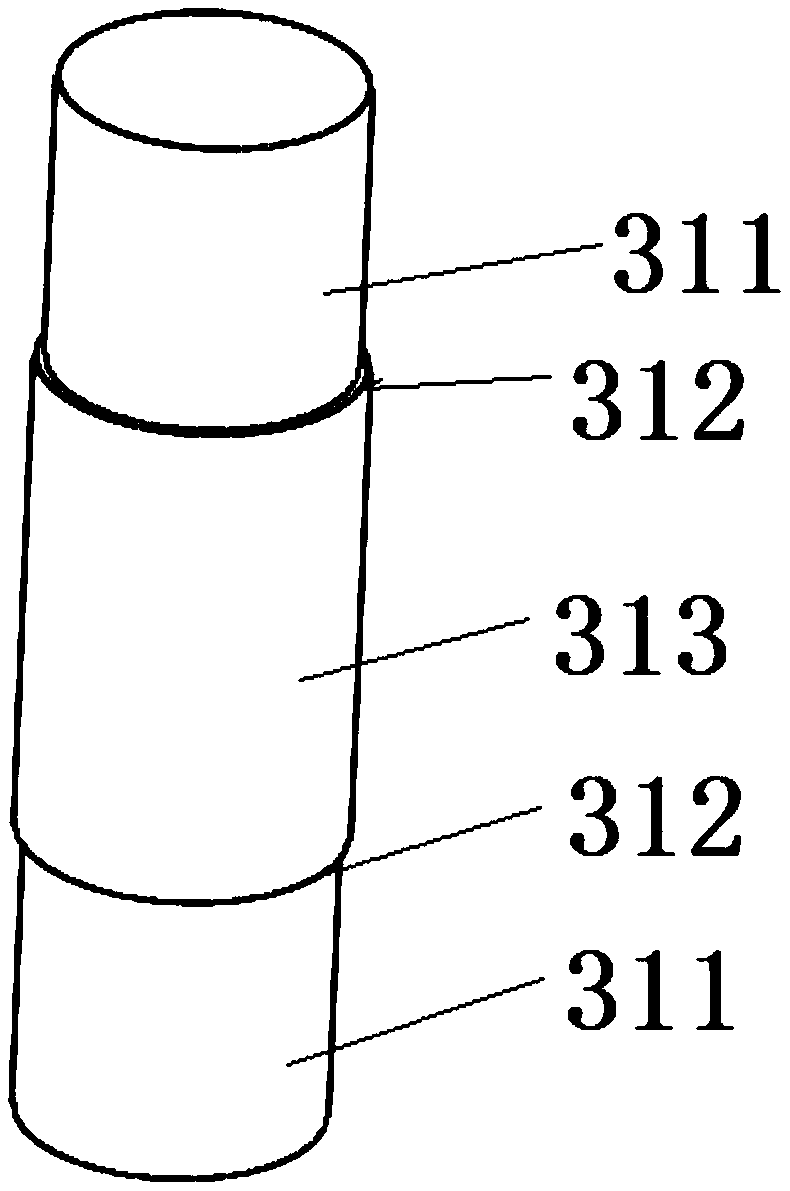

[0051] The hoisting base is cut into triangles from thick steel plates to carry the hoisting shaft. The hoisting base includes hoisting base A1 and hoisting base B2. Hoisting base A1 and hoisting base B2 are exactly the same. Here, hoisting base A1 is taken as an example to describe its structure; Such as figure 2 As shown, the lifting base A1 includes connecting edges, mounting holes, and weight-reducing triangular holes. In order to avoid stress concentration, round chamfers are provided at the corners of the weight-reducing triangular holes and lifting base A1; the connecting edges of the lifting base A1 include the first The connecting side 11, the second connecting side 12 and the bottom connecting side 13, the first connecting side 11 and the second connect...

Embodiment 2

[0066] Such as Figure 8 As shown, in this embodiment, in order to simplify the winding of the sling 8 during the use of the triangular hoisting device and improve efficiency, one of the hoisting shafts is changed to a bolt 5 or a pin shaft. When hoisting, the bolt 5 is removed and the One end of the sling 8 is connected with the lifting device, and the other end bypasses the bottom of the energy-saving preform 9 from the left to the right side of the energy-saving preform 9, and passes the left sling 8 through the open ends of the two lifting bases without lifting shafts Sleeve into the triangular lifting device, place the 8-shaped loop on the head of the sling 8 in the mounting hole between the two lifting bases, pass the bolt 5 or pin through the mounting hole, and then fix one end of the sling 8; After the hoisting operation is completed, the bolt 5 or pin shaft can be removed to easily loosen the sling 8.

[0067] By setting one of the hoisting shafts as a movable bolt 5 or ...

Embodiment 3

[0070] Such as Picture 9 As shown, in this embodiment, in order to further reduce the wear of the sling 8, a U-groove pulley 7 structure is provided on the outer diameter of the working part 313 of the two fixed lifting shafts of the triangular lifting device. During the lifting process, the lifting The cable 8 is located in the U-shaped groove of the pulley 7, which minimizes the friction between the hoisting shaft and the sling 8 and further reduces the wear of the sling 8; Picture 10 As shown, by adding the pulley 7 structure, the triangle hoisting device can be used as a pulley, greatly expanding the scope of application of the triangle hoisting device. The hoisting shaft of the two pulley 7 structure is matched with the fixed pulley set above to form a pulley block. The heavier energy-saving preform 9 can be lifted with a smaller driving force.

[0071] By setting the V-groove or U-groove pulley 7 structure on the outer diameter of the working part 313 of the hoisting shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com