Waterborne reflective thermal insulation coating

A reflective thermal insulation coating, water-based technology, applied in reflective/signal coatings, etc., can solve the problems of poor stability, dirt resistance and adhesion, insufficient thermal insulation, etc., to achieve good reflective thermal insulation effect, good adhesion effect, Good storage stability and dirt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

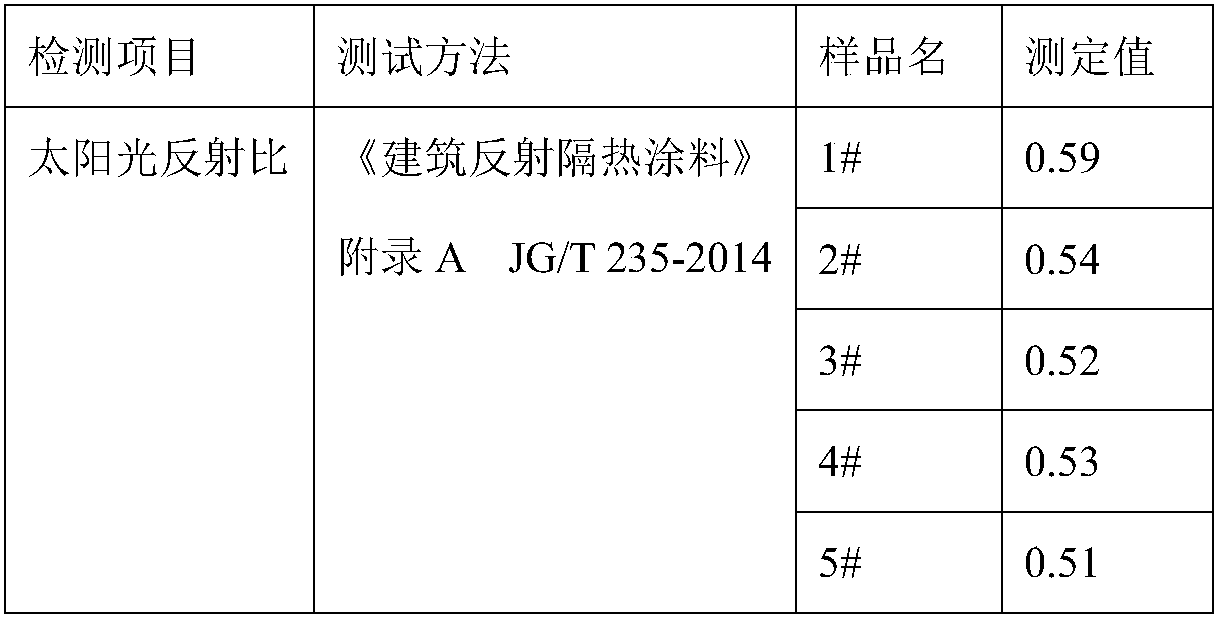

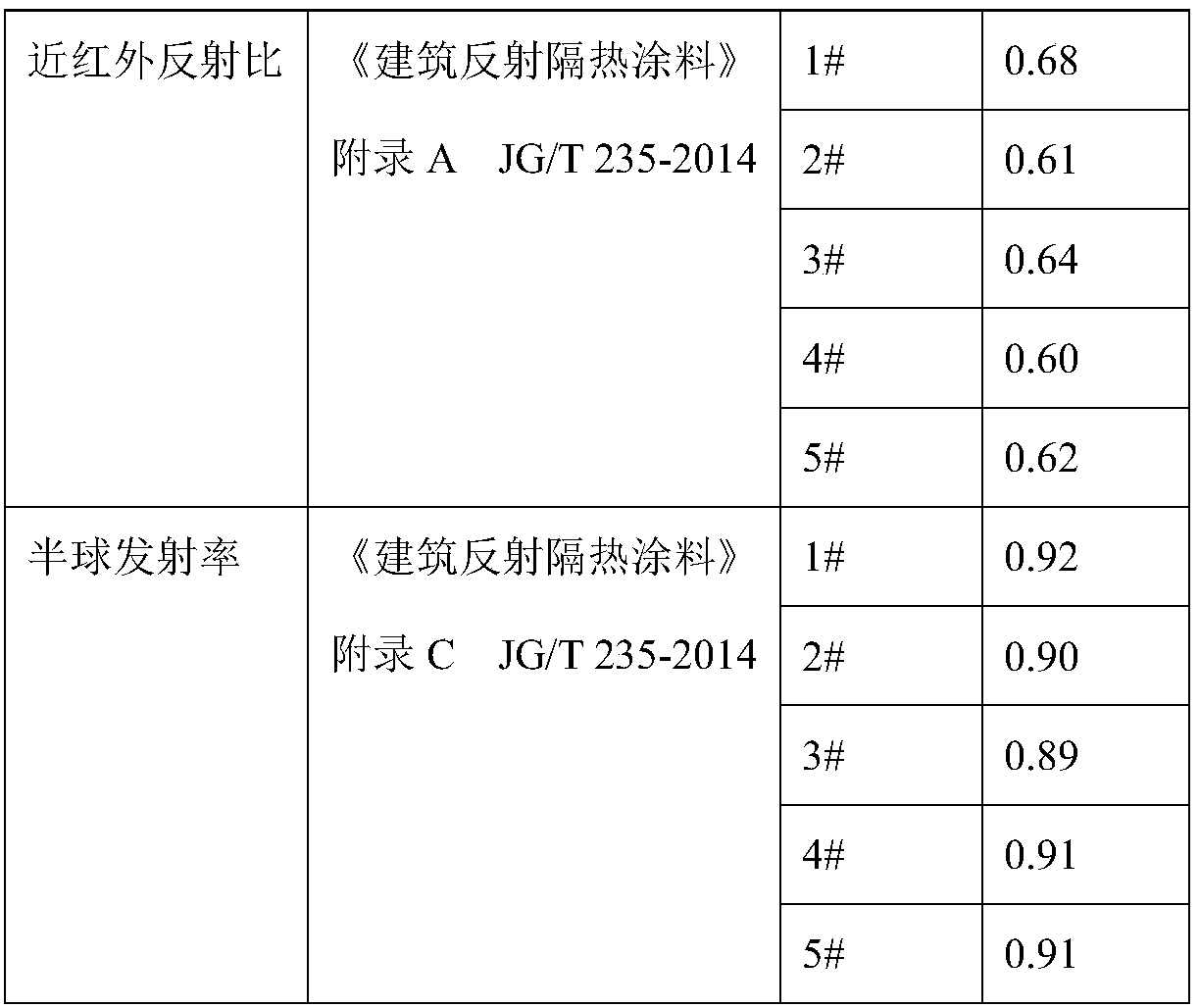

Embodiment 1

[0019] In the present embodiment, the water-based reflective heat-insulating coating includes the following raw materials in parts by weight:

[0020] 25g cellulose, 70g dispersant, 20g defoamer, 25g wetting agent, 20g bactericide, 15g pH regulator, 650g titanium dioxide near-infrared reflective powder, 1500g titanium dioxide, 750g calcined kaolin, 750g heavy calcium, 500g mica powder , Silicone acrylic emulsion 3000g, film-forming aid 240g, ethylene glycol 150g, foam suppressor 20g, leveling agent 40g, thickener 20g, water 2205g.

Embodiment 2

[0022] 20g cellulose, 60g dispersant, 10g defoamer, 20g wetting agent, 10g fungicide, 10g pH adjuster, 600g titanium dioxide near-infrared reflective powder, 1400g titanium dioxide, 700g calcined kaolin, 700g heavy calcium, 400g mica powder , Silicone acrylic emulsion 2800g, film-forming aid 200g, ethylene glycol 120g, foam suppressor 10g, leveling agent 30g, thickener 10g, water 2200g.

Embodiment 3

[0024] 30g cellulose, 80g dispersant, 30g defoamer, 30g wetting agent, 30g bactericide, 20g pH adjuster, 700g titanium dioxide near-infrared reflective powder, 1600g titanium dioxide, 800g calcined kaolin, 800g heavy calcium, 600g mica powder , Silicone acrylic emulsion 3200g, film-forming aid 250g, ethylene glycol 160g, foam suppressor 30g, leveling agent 50g, thickener 30g, water 2500g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com