Batch-wise purification, metering and water and impurity separation method of swill-cooked dirty oil

A technology for waste oil and grease, which is used in the recovery of fat/fatty acids from waste, production of fat, and recovery of fatty substances. It can solve the problems of high-quality oil pollution, inaccurate statistics of oil content in raw materials, and no batching, and reduce transportation. and control procedures, optimize weighing sampling operations, improve the effect of the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

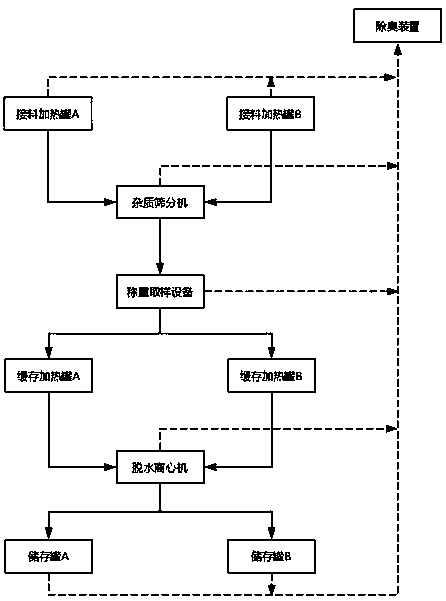

Image

Examples

Embodiment 1

[0020] The gutter oil cleared in the sewer grease trap has an oil content of about 40%, a high content of water and impurities, and a high viscosity; pour the gutter oil into the heating tank for inferior oil, heat it to 50°C with direct steam and stir Homogenize and improve the fluidity of the oil; open the valve at the bottom of the tank, the waste oil enters the large material screening machine, removes the large particle size impurities such as plastics and fibers with a particle size above 2mm in the oil, and the screened oil flows to the scale Re-sampling tank, after the weighing reading is stable, take a sample of the oil in the tank to analyze the water content, and calculate the net oil amount of the batch; after the sampling is completed, pump the oil into the low-quality oil heating buffer tank, directly heat the steam to 80°C, and heat The final waste oil enters the three-phase centrifuge to separate the water and solid residue in the oil. The water quality ratio in...

Embodiment 2

[0022] The waste oil used for repeated frying has an oil content of about 90%, less water and impurities, and a higher viscosity; pour the waste oil into a high-quality oil heating tank, heat it to 40°C with direct steam, and stir it homogeneously. Improves oil mobility. Open the valve at the bottom of the tank, and the gutter oil enters the large material screening machine to remove the large particle size impurities such as plastics and fibers with a particle size of more than 2mm in the oil, and the sieved oil flows to the weighing sampling tank by itself, and waits for the weighing reading After stabilization, the oil in the tank is sampled to analyze the water content, and the net oil volume of the batch is calculated; after the sampling is completed, the oil is pumped into the high-quality oil heating buffer tank, and the steam is indirectly heated to 80°C, and the heated waste oil enters the three-phase centrifuge The machine separates the water and solid residue in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com