Template positioning tool and method for external wall concrete cornice pouring

A technology of concrete and pouring concrete, which is applied in the preparation of formwork/formwork/work frame, building components on site, construction, etc. It can solve the problems of unsatisfactory surface appearance quality, difficulty in controlling the level of concrete eaves, and easily damaged concrete eaves Problems such as edges and corners, to achieve good promotion and application value, solve reinforcement difficulties, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

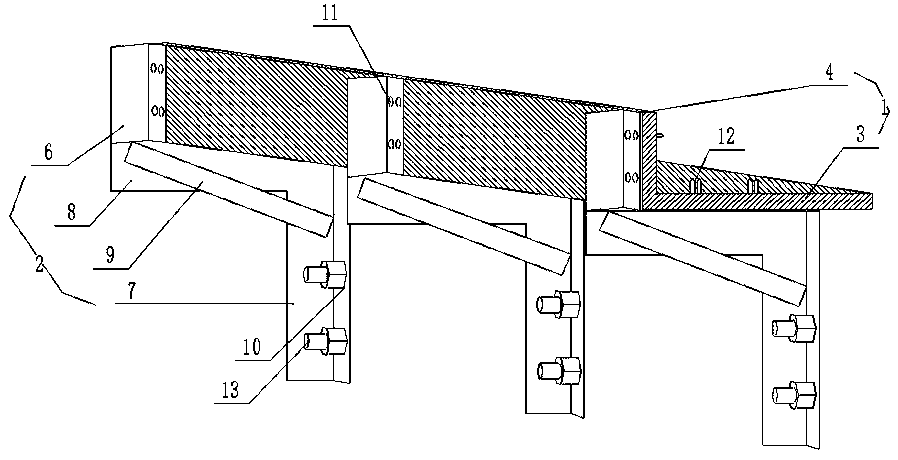

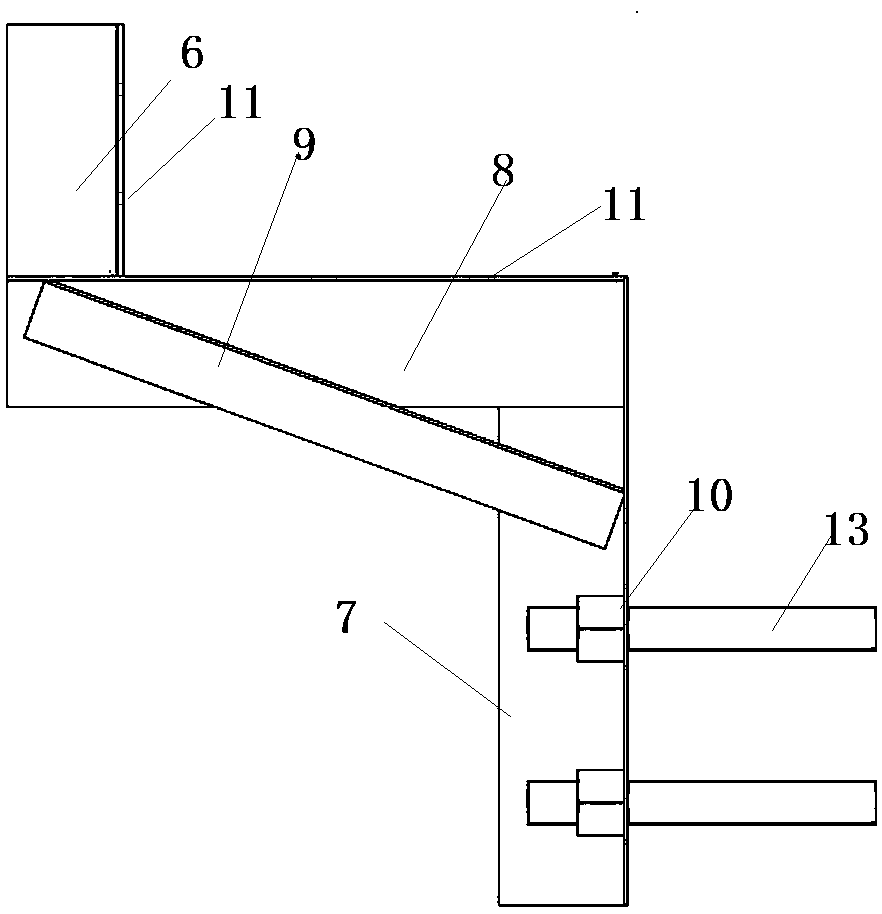

[0043] A positioning tool for pouring concrete overhangs on exterior walls, comprising an overhang formwork 1 for pouring concrete and a support frame 2 arranged at the lower part of the overhang formwork;

[0044] The eaves formwork 1 is a long formwork with an L-shaped cross section, which is divided into a flat plate 3 and a vertical plate 4, and the edges of the flat plate 3 and the vertical plate 4 are provided with a plurality of first installation holes;

[0045] The support frame includes an upper vertical section 6, a lower vertical section 7, a horizontal section 8 and a corner brace 9 between the upper vertical section and the lower vertical section, and the horizontal section and the lower vertical section are arranged between Angle brace 9, described lower vertical section is provided with fixing hole 10, and described upper vertical section and horizontal section are provided with second installation hole 11, and described second installation hole 11 and first ins...

Embodiment 2

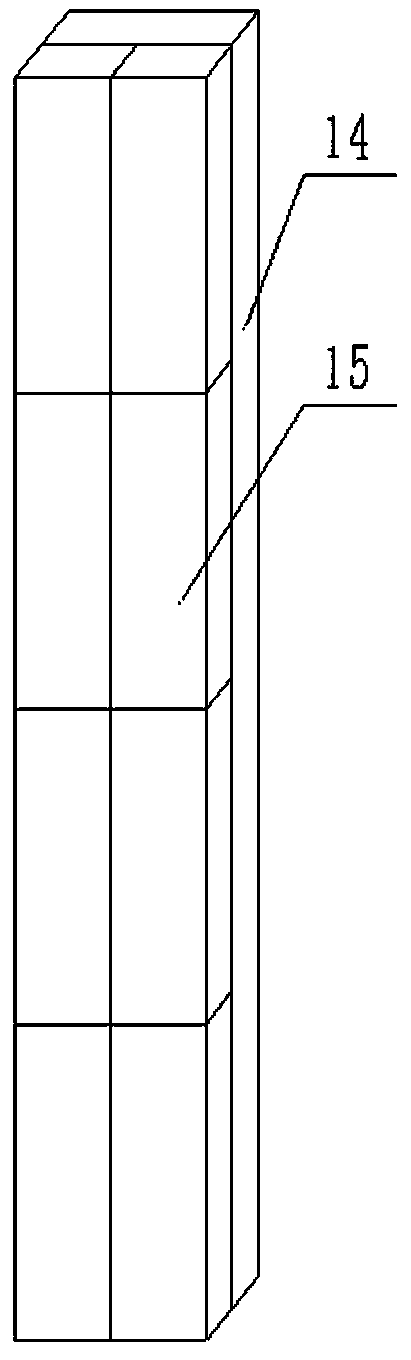

[0055] Such as image 3 as shown,

[0056]In the positioning tool described in Example 1, the overhanging formwork does not use the plug-in structure of bumps and grooves, but adopts an integrated structure. The integrated overhanging formwork structure is divided into upper and lower layers, and the upper layer is a flexible plate 14. The lower layer is spliced by a plurality of rigid boards 15. The lower rigid board and the upper flexible board are fixedly bonded. The length of the rigid board is greater than the distance between two adjacent support frames. In actual use, the overhanging eaves The formwork is unfolded, erected on the support frame, and fixed by installing dovetail screws in the first mounting hole on the edge; the upper flexible board is an integrated board, which can fold the cornice formwork when not in use, and the flexible board can be used when in use. The surface of the finished overhanging eaves is smooth and consistent, and there will be no lap j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com