Well wall crack printing device

A technology for printing devices and fissures, which is used in wellbore/well components, earth-moving drilling, etc., can solve the problems of low resolution, inability to obtain the number and distribution of fissures, and difficulty in determining the development status of fissures and holes, and achieves convenient operation. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

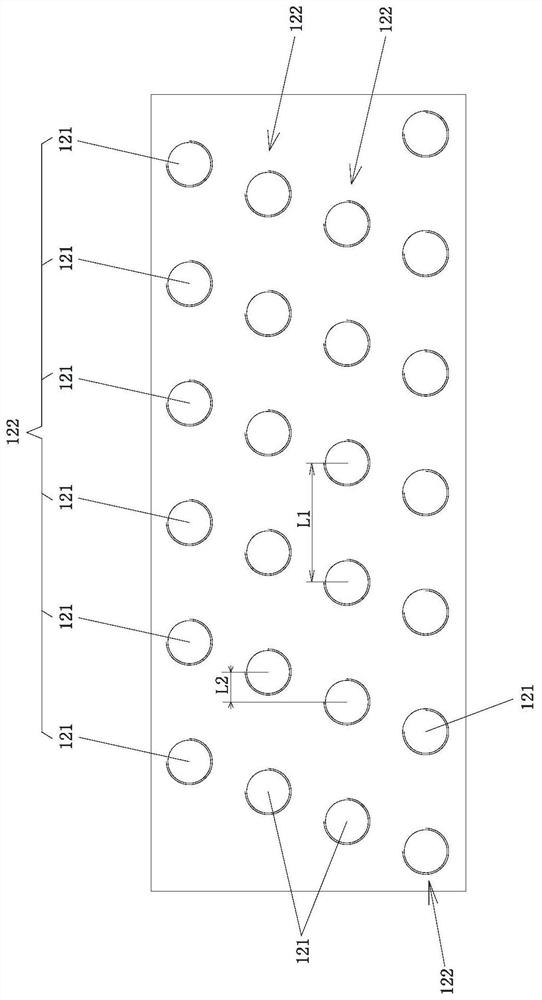

[0059] In a specific example of the present invention, a specific example of a wellbore fracture printing device designed for a wellbore with a diameter of 215.9mm is as follows:

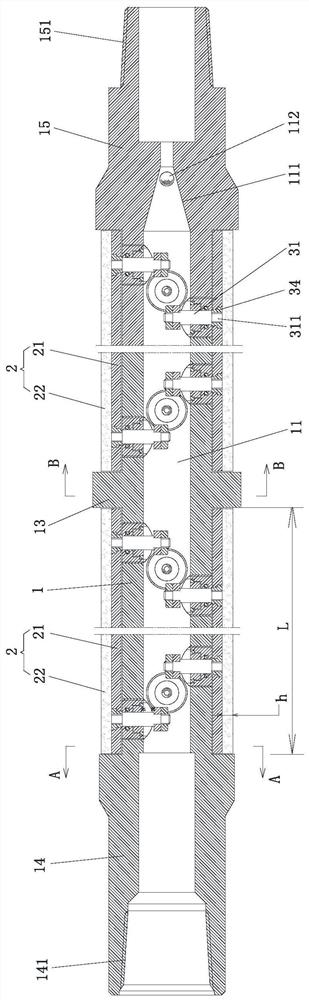

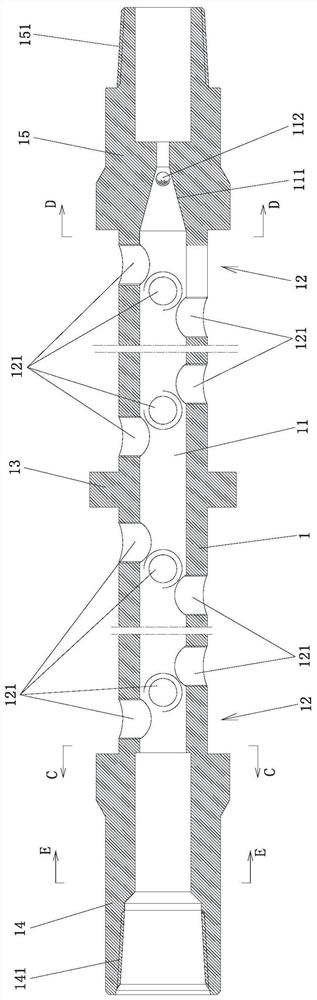

[0060] The inner frame structure 1 is a stainless steel pipe with a length of 2709 mm, such as figure 1 As shown, from left to right are the upper joint 14, the printing mechanism 2, the centralizing ring 13, the printing mechanism 2 and the lower joint 15. in:

[0061] The outer diameter of the left end of the upper joint 14 is 165mm, which is processed with a 5" drill pipe box. The outer diameter of the right end of the upper joint 14 is 210mm, and there are four angles respectively -30°~30°, 60°~120°, 150° ° ~ 210 °, 240 ° ~ 300 ° upper liquid flow tank 143, such as Figure 8As shown, the outer diameter D1 of the upper liquid flow tank 143 is 210 mm, and the inner diameter D2 is 192 mm.

[0062] Such as figure 1 with Figure 8 As shown, the inner diameter d1 of the installation ring groove 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com