Backlight module and display device

A backlight module and backplane technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems affecting the appearance of the back of the display device, the reflective sheet is easy to warp, and the production efficiency is low, so as to avoid warping and fit. The effect of compact and leveling, improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

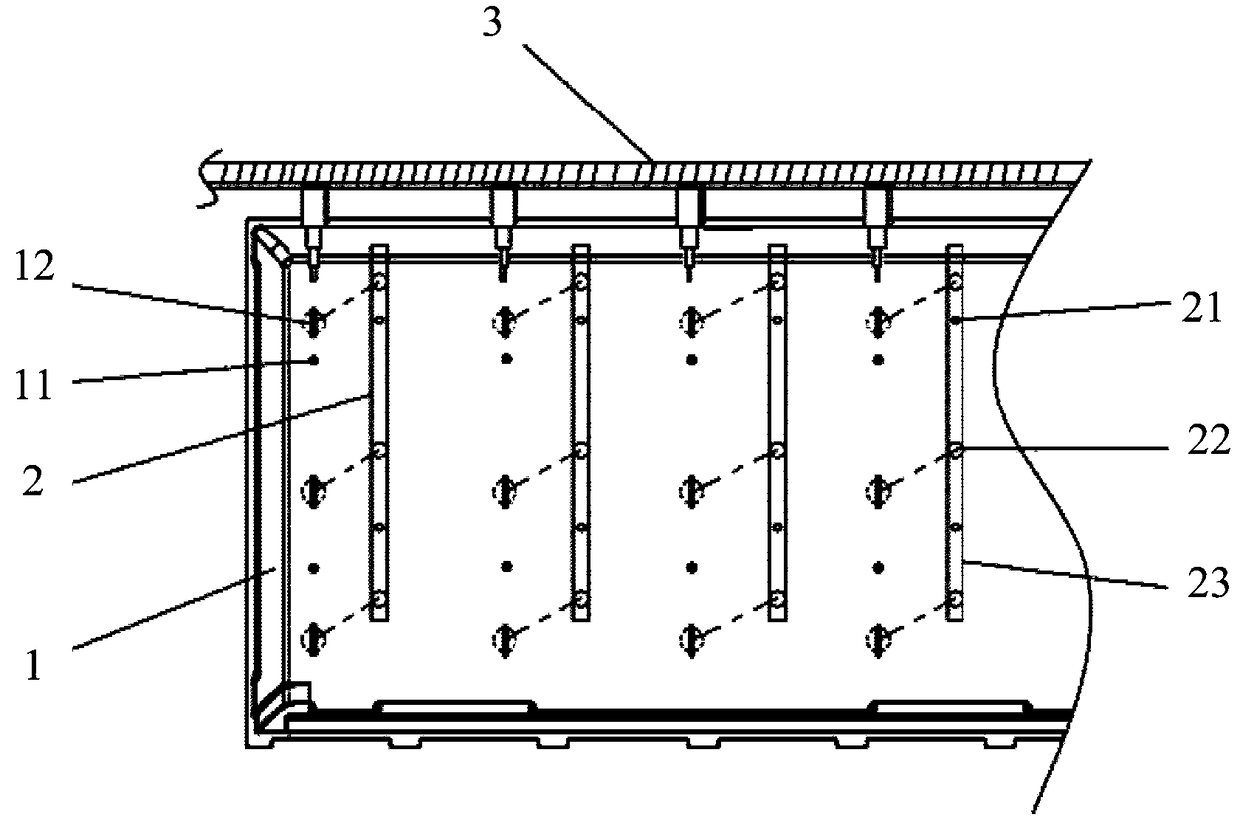

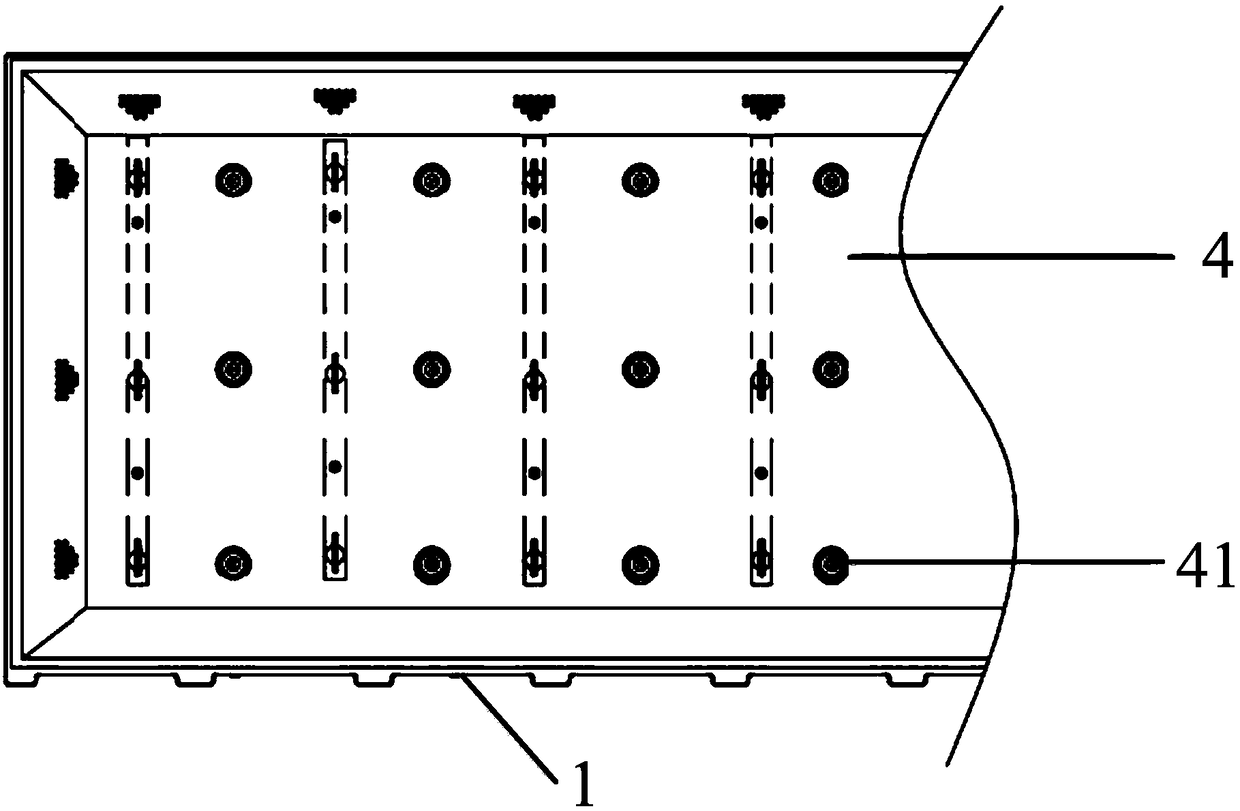

[0037] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

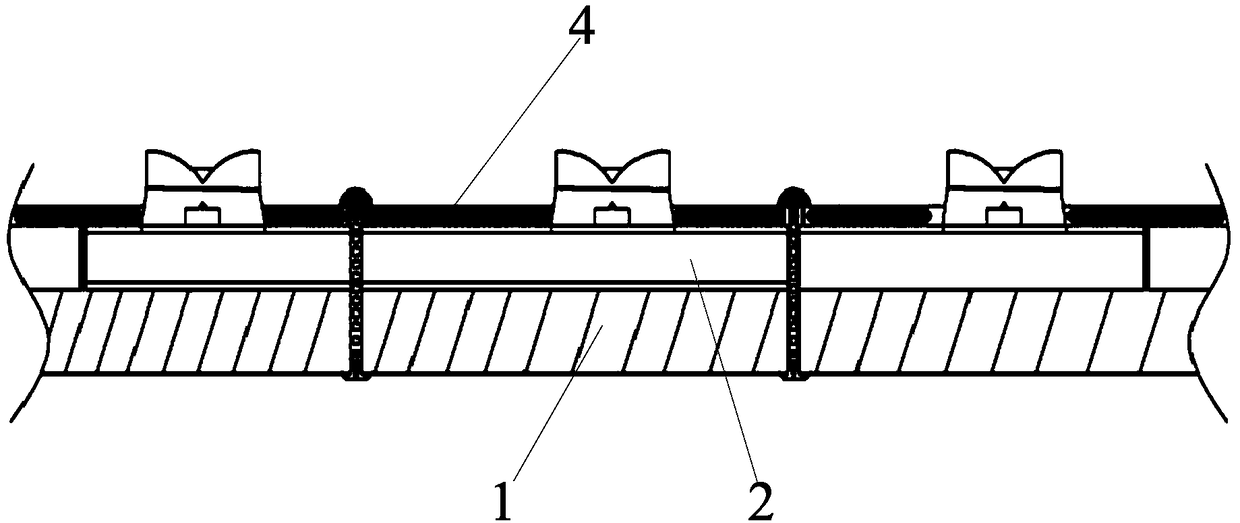

[0038] figure 1 It is a schematic diagram of using screws to lock the LED light bar 2 and the reflector 4 in the prior art, such as figure 1 As shown, since the PCB (printed circuit board) of the LED light bar 2 has a certain thickness, if the screws are not locked properly or are too tight, the LED light bar 2 will be warped, which will affect the display effect of the picture. Moreover, locking the screws will reduce the production efficiency, and the required material and labor costs are high, which is particularly obvious in large-size direct-lit display devices.

[0039] The embodiments of the present invention aim at the above-mentioned problems, and provide a backlight module and a display device, which can solve the problems o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com