A heat sink with good heat dissipation effect

A heat dissipation effect and heat sink technology, which is applied in the field of radiators and electrical appliances, can solve the problems affecting the use effect and service life of electrical appliances, and the heat dissipation effect of radiators is not ideal, so as to achieve good heat dissipation effect, easy to fix, and firm radiator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

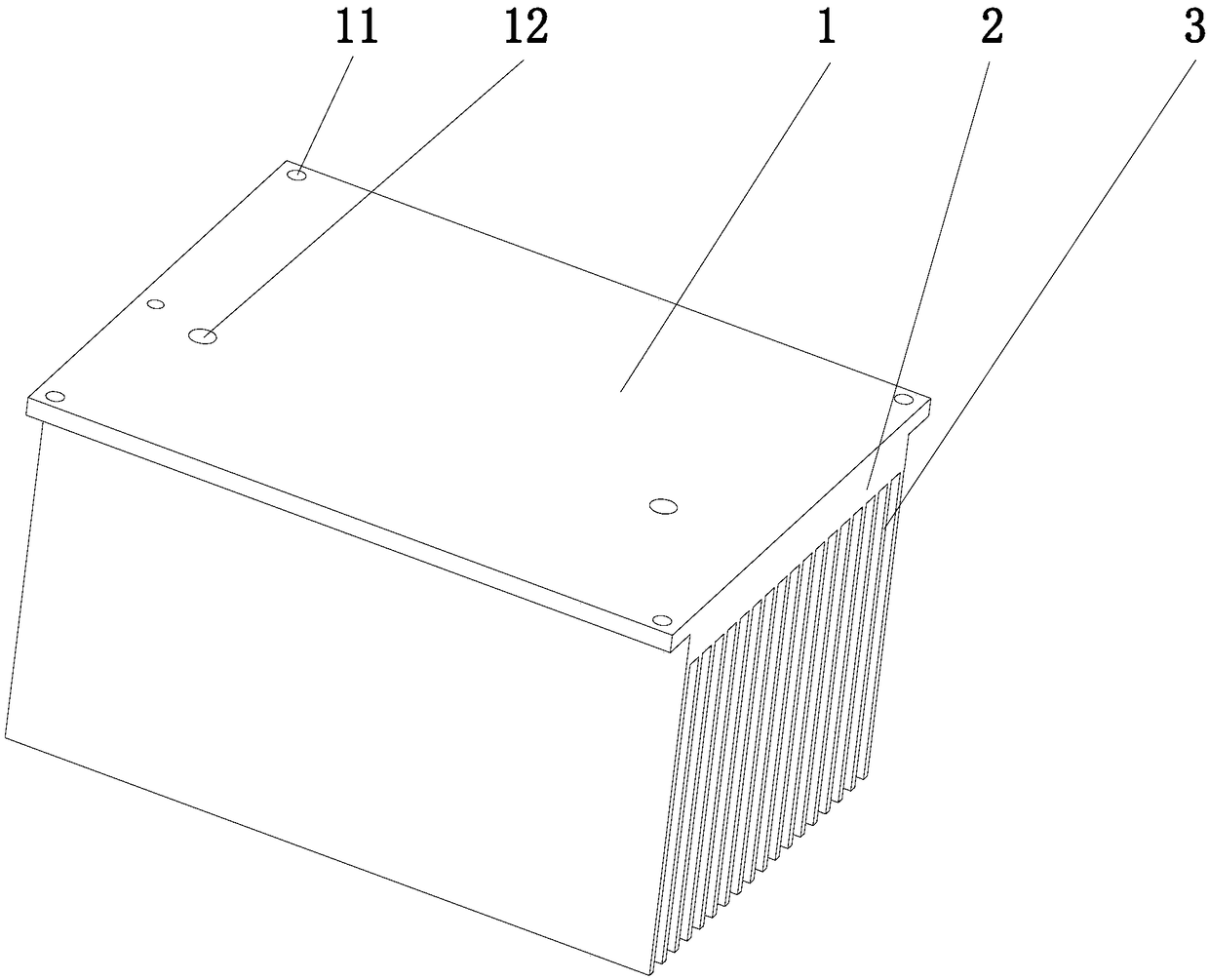

[0016] refer to figure 1 , a heat sink with good heat dissipation effect in the present invention comprises a base plate 1, a reinforcement plate 2, a first fixing hole 11, a second fixing hole 12, and a heat dissipation plate 3. The base plate 1 is arranged horizontally, and the base plate 1 is provided with several first A fixing hole 11 and a second fixing hole 12, a reinforcing plate 2 is fixed on the bottom of the base plate 1, and several cooling plates 3 are fixed on the bottom of the reinforcing plate 2, and the cooling plates 3 are evenly distributed on the bottom of the reinforcing plate 2, The heat dissipation plates 3 are parallel to each other, the heat dissipation plate 3 is perpendicular to the reinforcement plate 2, the base plate 1, the reinforcement plate 2, and the heat dissipation plate 3 are of an integrated structure, and the first fixing hole 11 and the second fixing hole 12 are vertical holes , the first fixing hole 11 and the second fixing hole 12 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com