Herbage chopping machine for animal husbandry feeding

A shredder and animal husbandry technology, applied in agricultural machinery and tools, application, agriculture, etc., can solve the problems of not being able to save manpower, not being able to collect grass to control feeding, not being able to chop grass in multiple stages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

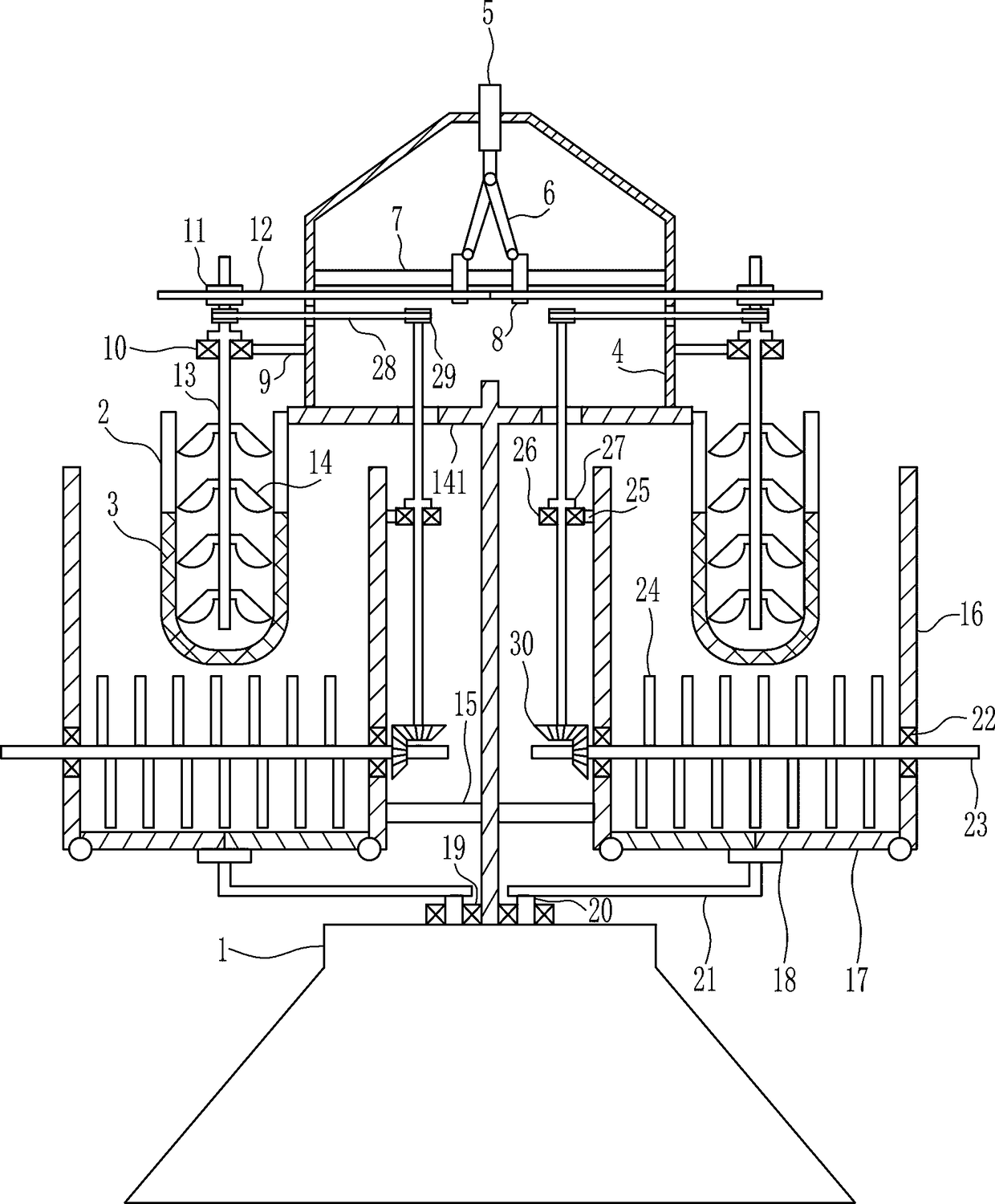

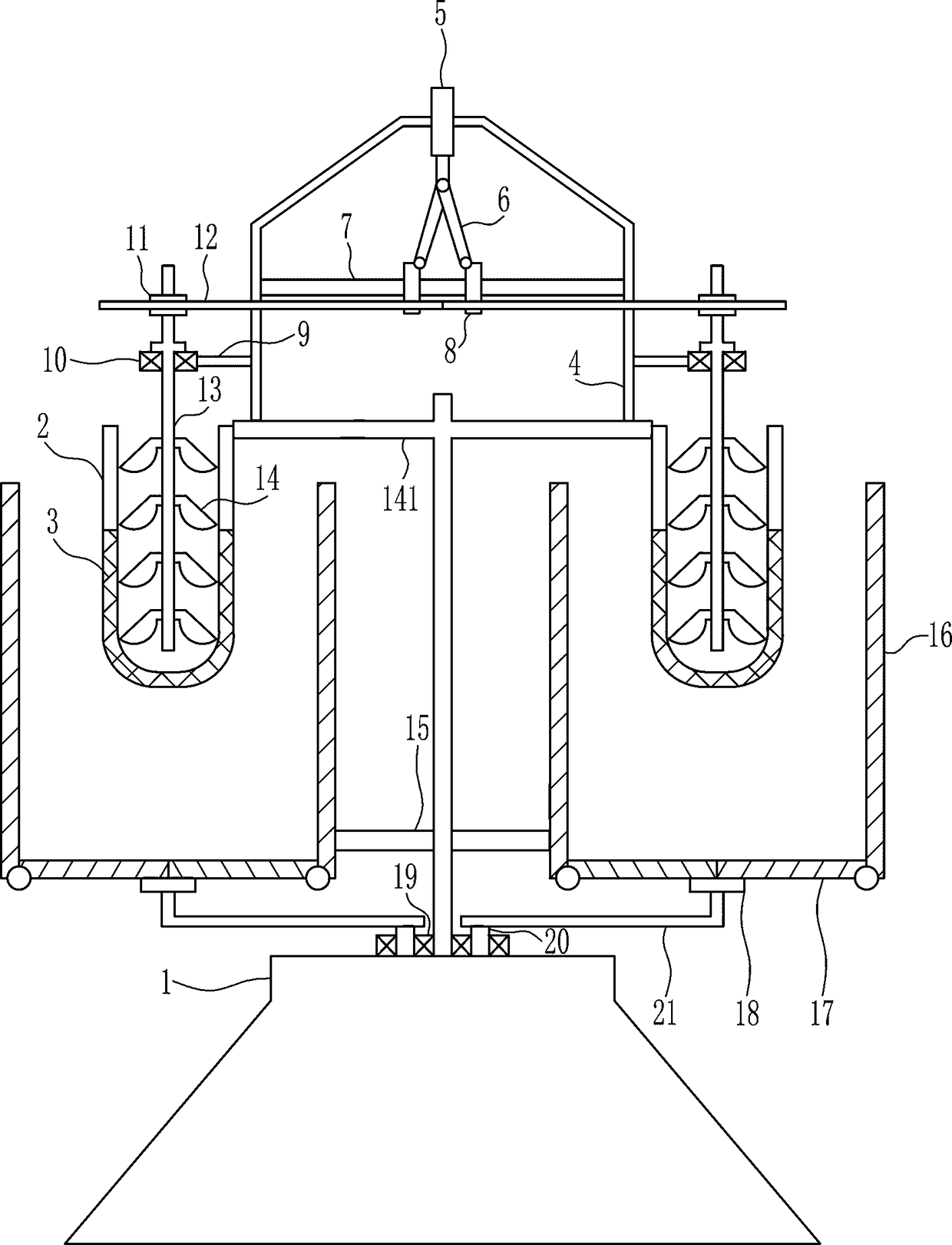

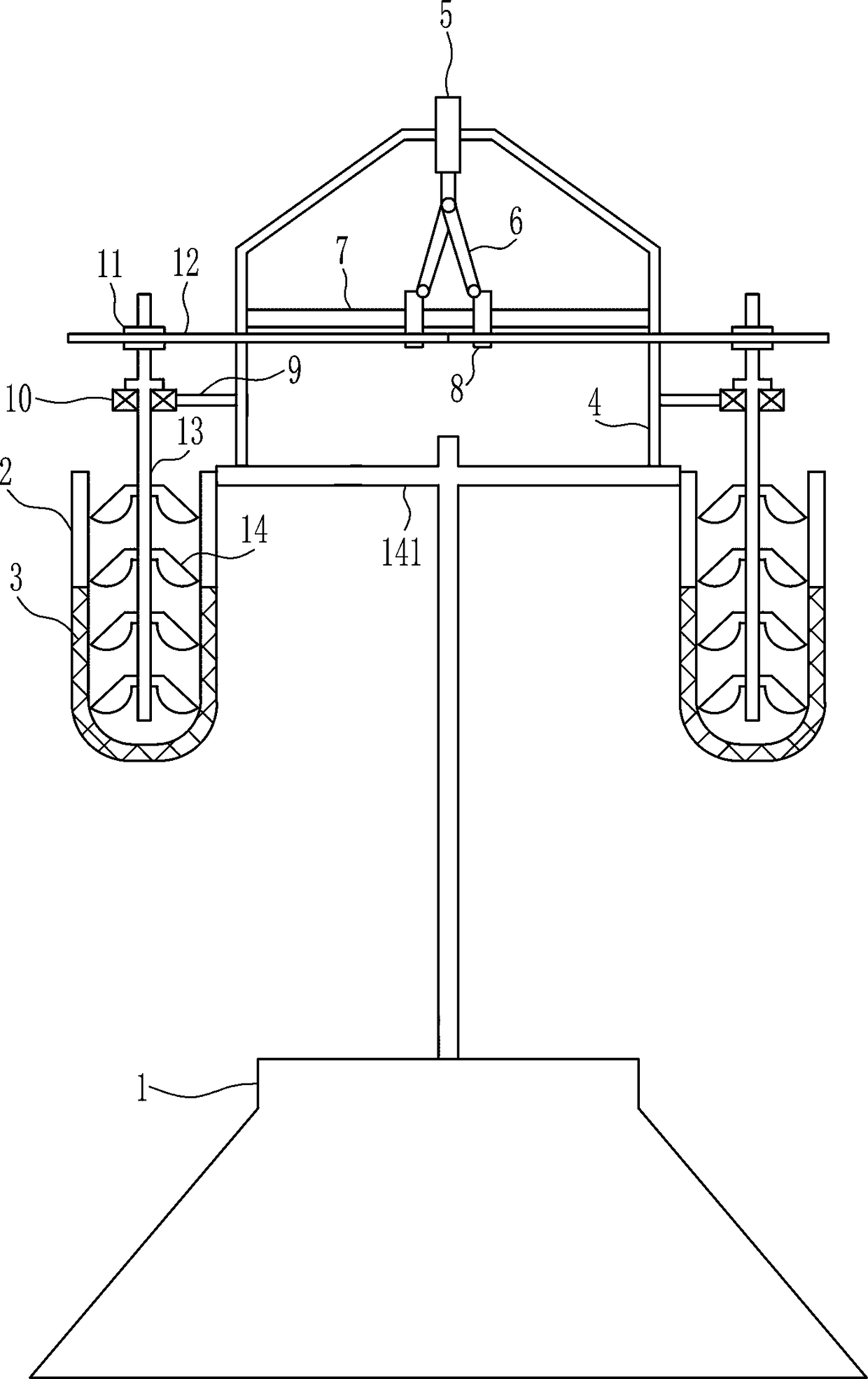

[0024]A pasture chopper for animal husbandry feeding, such as Figure 1-5 As shown, it includes a mounting seat 1, a chopping frame 2, a filter screen 3, a mounting frame 4, a cylinder 5, a connecting rod 6, a guide rail 7, a sliding sleeve 8, a mounting rod 9, a first bearing seat 10, and a first gear 11 , rack 12, the first rotating rod 13, the first blade 14 and the connecting frame 141, the connecting frame 141 is connected in the middle of the top of the mounting seat 1, the left and right ends of the connecting frame 141 are connected with the chopping frame 2, two chopping frames 2 bottoms are all connected with filter screen 3, connecting frame 141 top is connected with mounting frame 4, is provided with cylinder 5 in the middle of mounting frame 4 top wall, is connected with two connecting rods 6 on the telescoping rod of cylinder 5, and mounting frame 4 left and right sides A guide rail 7 is connected between the inner middle of the two walls, and two sliding sleeves...

Embodiment 2

[0026] A pasture chopper for animal husbandry feeding, such as Figure 1-5 As shown, it includes a mounting seat 1, a chopping frame 2, a filter screen 3, a mounting frame 4, a cylinder 5, a connecting rod 6, a guide rail 7, a sliding sleeve 8, a mounting rod 9, a first bearing seat 10, and a first gear 11 , rack 12, the first rotating rod 13, the first blade 14 and the connecting frame 141, the connecting frame 141 is connected in the middle of the top of the mounting seat 1, the left and right ends of the connecting frame 141 are connected with the chopping frame 2, two chopping frame 2 bottoms are all connected with filter screen 3, connecting frame 141 top is connected with mounting frame 4, is provided with cylinder 5 in the middle of mounting frame 4 top wall, is connected with two connecting rods 6 on the telescoping rod of cylinder 5, and mounting frame 4 left and right sides A guide rail 7 is connected between the inner middle of the two walls, and two sliding sleeves...

Embodiment 3

[0029] A pasture chopper for animal husbandry feeding, such as Figure 1-5 As shown, it includes a mounting seat 1, a chopping frame 2, a filter screen 3, a mounting frame 4, a cylinder 5, a connecting rod 6, a guide rail 7, a sliding sleeve 8, a mounting rod 9, a first bearing seat 10, and a first gear 11 , rack 12, the first rotating rod 13, the first blade 14 and the connecting frame 141, the connecting frame 141 is connected in the middle of the top of the mounting seat 1, the left and right ends of the connecting frame 141 are connected with the chopping frame 2, two chopping frames 2 bottoms are all connected with filter screen 3, connecting frame 141 top is connected with mounting frame 4, is provided with cylinder 5 in the middle of mounting frame 4 top wall, is connected with two connecting rods 6 on the telescoping rod of cylinder 5, and mounting frame 4 left and right sides A guide rail 7 is connected between the inner middle of the two walls, and two sliding sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com