Biochip and chip control method

A biochip and control method technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problem of large consumption of reagents, multiple liquid paths and waste liquid discharge, and inability to achieve large-scale automated analytical instruments. Accuracy and other issues, to achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

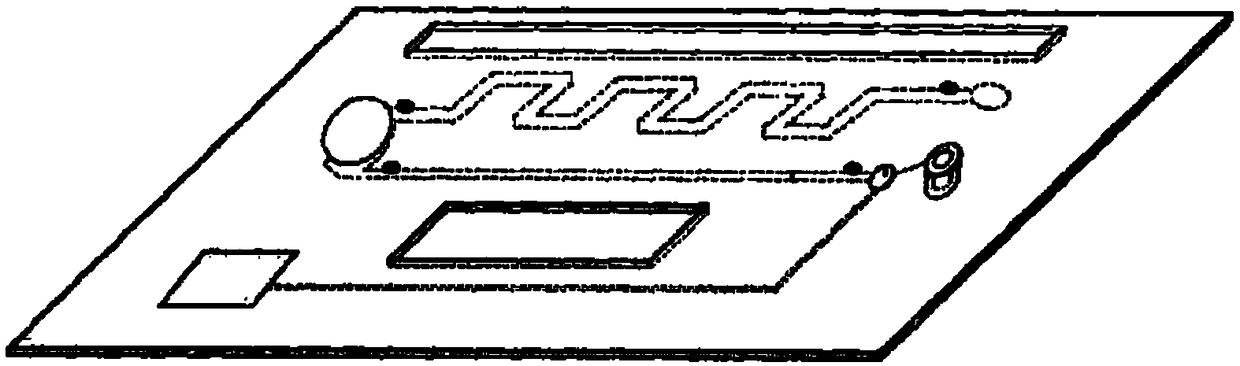

[0121] A biochip, such as Figure 5 , shown in 11,12, it comprises chip substrate 12, is arranged on the quantitative sampling device 20 on the chip substrate 12, a plurality of reagent chambers 16 and reactor 10; Each described reagent chamber 16 is provided with described reactor 10 communicated with the pipelines 17, each pipeline 17 is provided with a normally closed micro-valve 18; the quantitative sampling device has a sample outlet 402, and the sample outlet 402 is communicated with the reactor 10. The liquid inlet end of the pipeline 17 communicates with the liquid outlet end of the reagent chamber 16, and the liquid outlet ends of the pipeline 17 are located above the reactor 10; the sample outlet 402 is located at the top of the reactor 10. above.

[0122] Such as Figure 5-7, 11, 12, the normally closed microvalve in the pipeline 17 is divided into a first pipeline 171 and a second pipeline 172 . The reagent chamber 16 is used to store the liquid 22. The bottom e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com