A steel pipe painting robot

A technology of robots and steel pipes, which is applied in painting booths, manipulators, spraying devices, etc., can solve the problems of not being able to adapt to the diameter of steel pipes, affect the use effect, and uneven painting, so as to ensure normal use effects, improve work efficiency, Uniform effect of spray paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

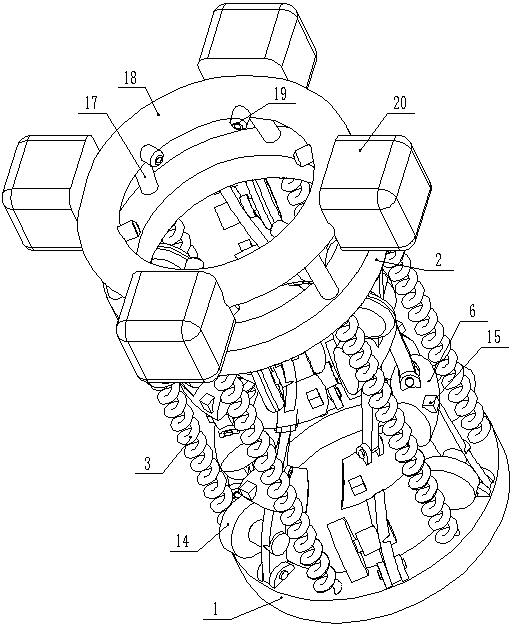

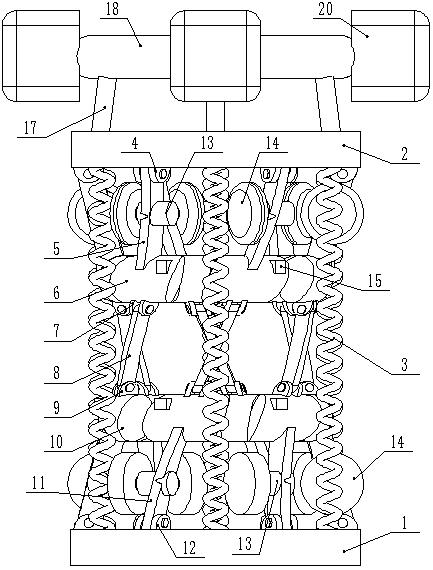

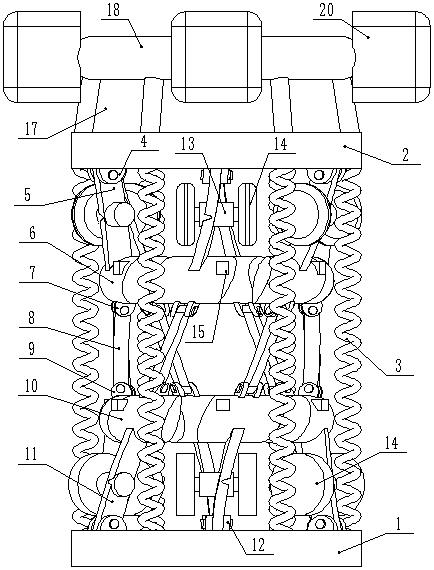

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a steel pipe painting robot includes a lower ring body 1 and an upper ring body 2, the lower ring body 1 and the upper ring body 2 are parallel to each other, and the centers of the lower ring body 1 and the upper ring body 2 are congruent Shaft, between the lower ring body 1 and the upper ring body 2, a plurality of contraction springs 3 are vertically fixed, and the upper end of the lower ring body 1 is fixed between the contraction springs 3, and a plurality of fourth fixed blocks 12 are fixed, and the upper The lower end of the annular body 2 is located between the contraction springs 3 and is fixed with a plurality of first fixed blocks 4, and the lower end of the first fixed block 4 is hinged with a first connecting rod 5, and the first connecting rod 5 is obliquely fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com