Automatic adhesive dispensing process for lens waterproofing

An automatic glue dispensing and glue dispensing technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of waterproof, poor corrosion resistance, short service life, etc., to save time, reduce operation difficulty, and process low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

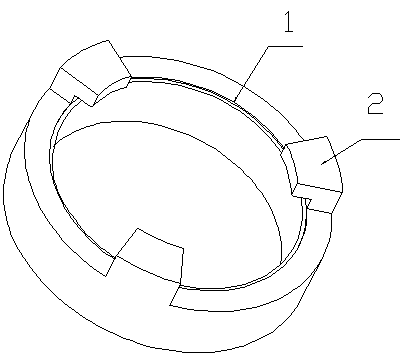

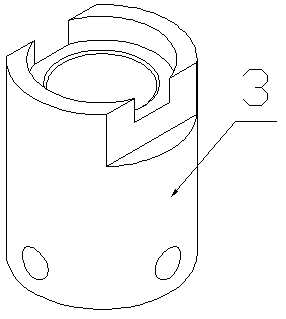

[0030] refer to figure 1 and 2 , the present embodiment provides a lens waterproof automatic dispensing process, including a dispensing device and a dispensing method, the dispensing device includes a dispensing jig 3 for placing the lens inside and a dispensing jig 3 arranged on the dispensing jig 3 The dispensing gland 1 above, the dispensing fixture 3 is cylindrical, the size of the inner wall of the dispensing fixture 3 matches the size of the lens, and the upper end of the dispensing fixture 3 is provided with several Notch, the glue dispensing gland 1 is ring-shaped, and several protruding corners 2 are arranged on the glue dispensing gland 1 . In this embodiment, two notches are provided on the dispensing jig 3 , and three protruding corners 2 are provided on the dispensing gland 1 . When assembling, the convex angle 3 faces upward, fix the lens with the dispensing gland 1, put it into the dispensing fixture 3, turn the dispensing gland 1, and align the convex angle 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com