Dustproof device for cement mixing machine

The technology of a cement mixer and a dust-proof device is applied in the directions of cement mixing device, clay preparation device, raw material supply device, etc., which can solve the problems of dust blockage, economic loss, and great harm to engineering computers, and achieve the effect of preventing dust from coming out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

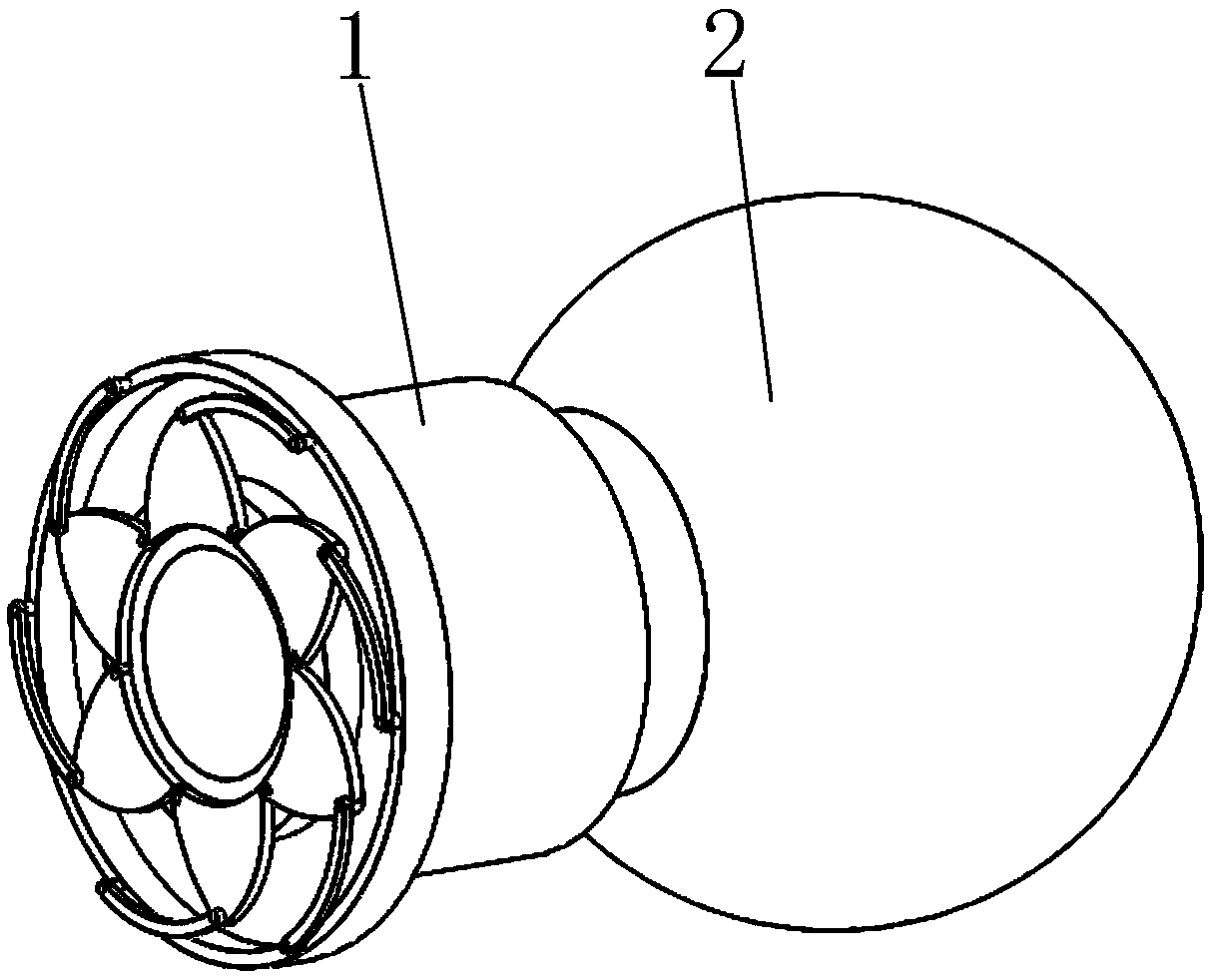

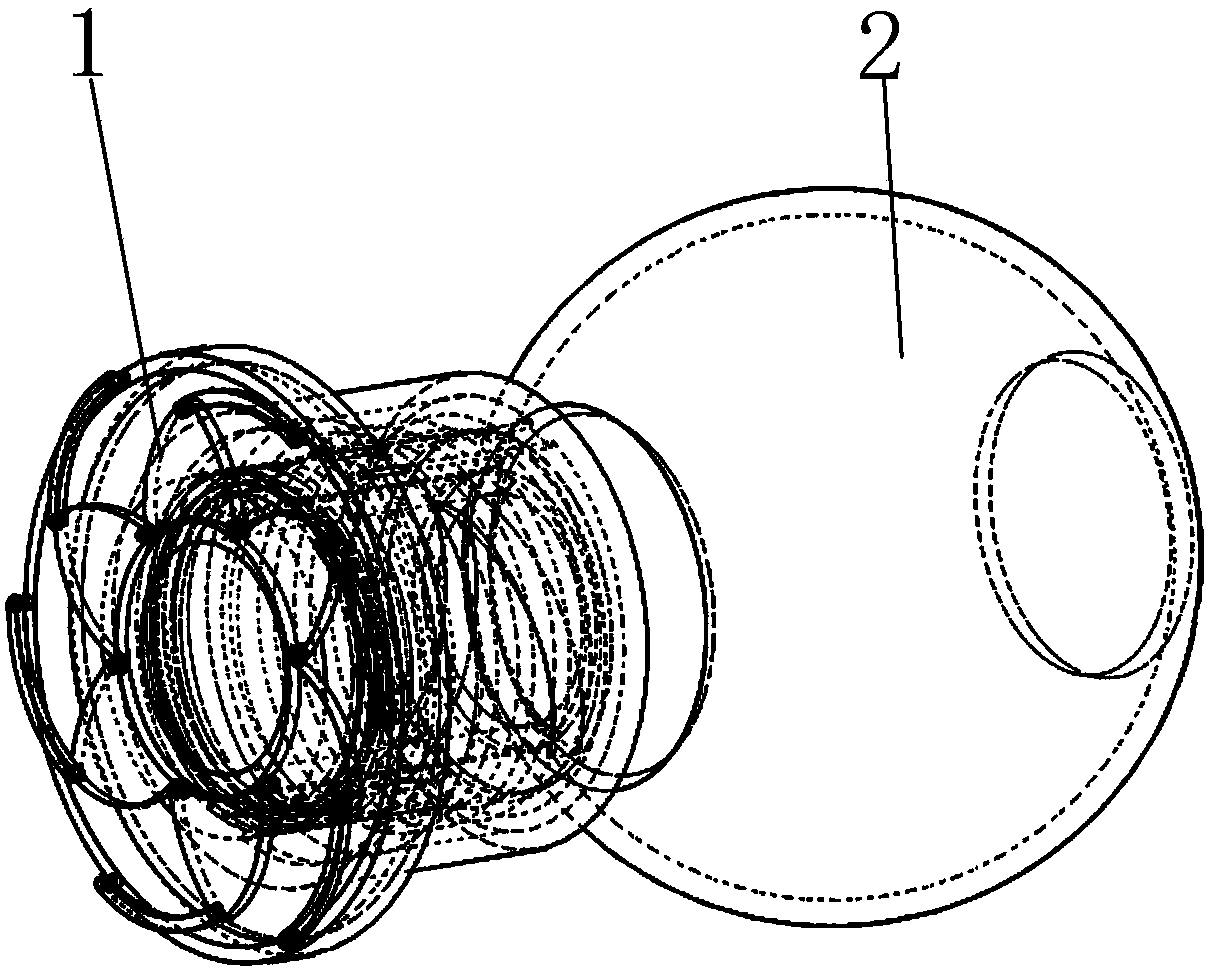

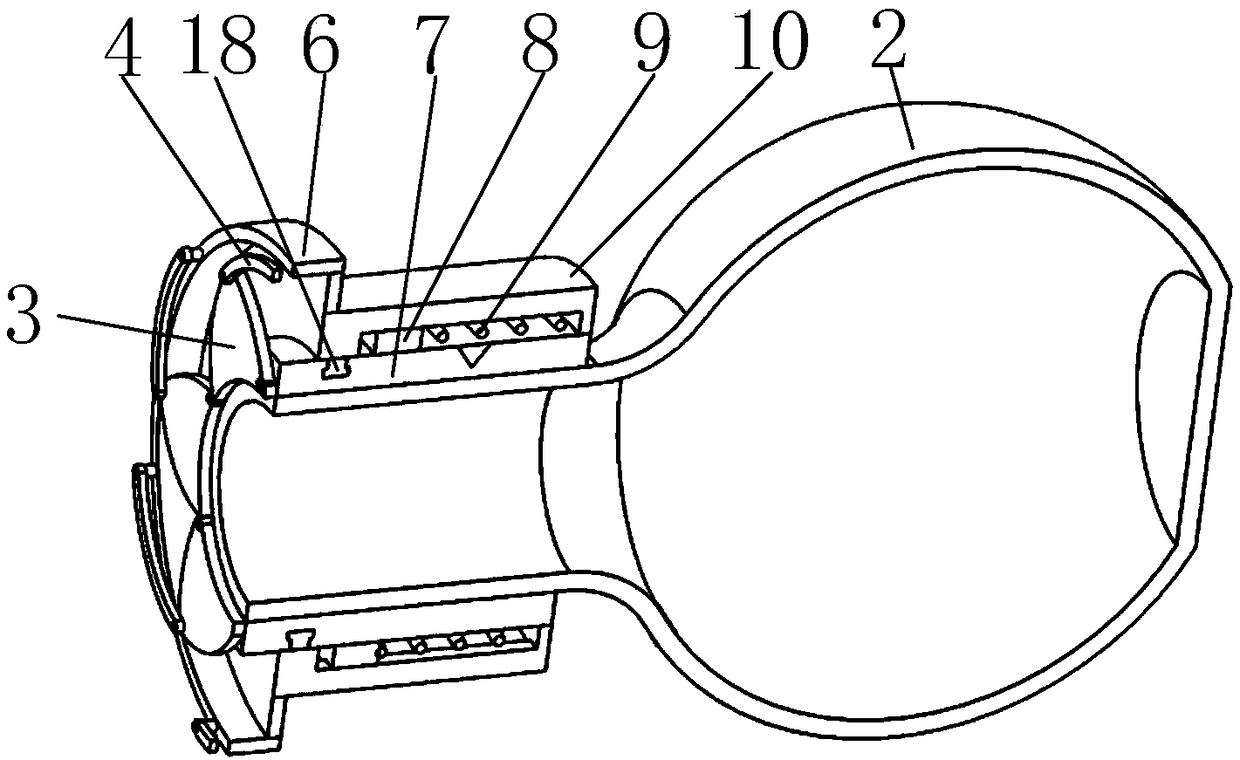

[0049]The specific implementation method is as follows: firstly, the equipment of the present invention can be installed in a self-falling mixer whose cement mixing shell 2 is driven to rotate by a driving device, and can also be installed on a forced mixer whose blades in the cement mixing shell 2 are driven to rotate by a driving device, but the two The conditions that all similar cement mixers need to meet are that the loading work is performed when the opening end of the cement mixing shell 2 is raised up, and the unloading work is performed when the opening end of the cement mixing shell 2 is tilted down; when the equipment of the present invention is installed on the When the cement mixing shell 2 on the drop mixer is on, when the cement mixing shell 2 is in a horizontal state, the cement mixer will perform the normal work of mixing cement, and at this time the cement mixing shell 2 will be driven by the driving device to rotate Movement and rotation requires slow start o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com