Adjusting device and hydraulic machine

A technology of adjusting device and adjusting chamber, which is applied in the field of hydraulic presses, and can solve problems such as damage to the sealing contour of the valve seat of the check valve, failure of the spring seat ring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

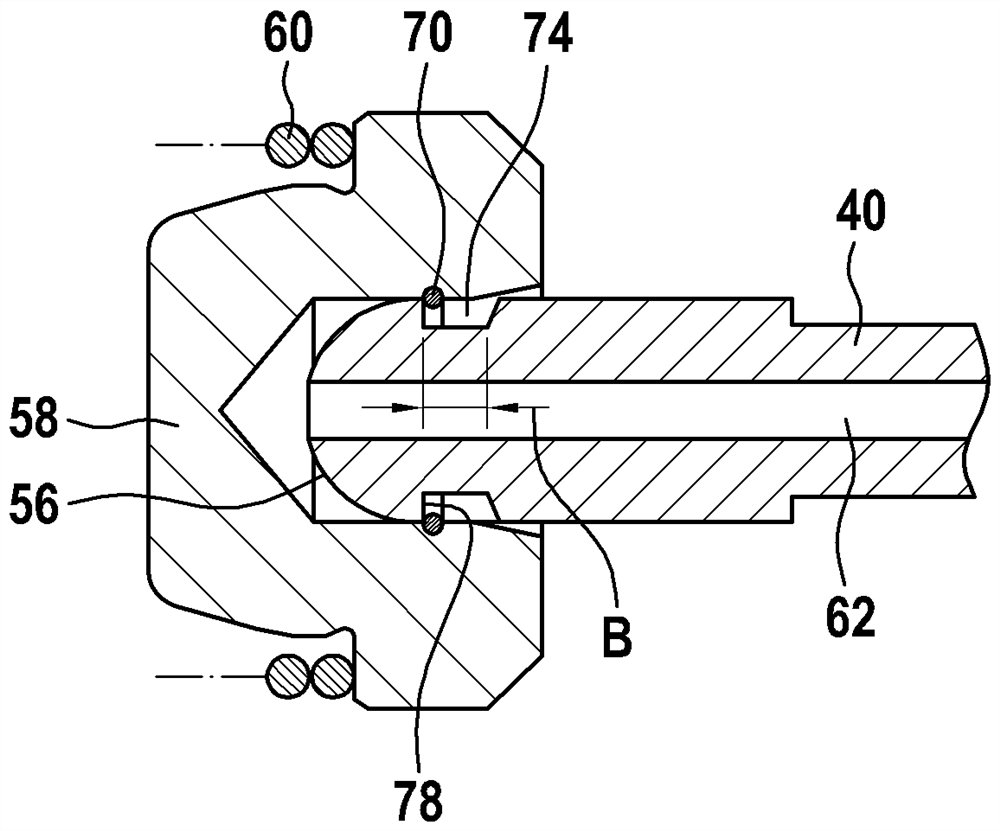

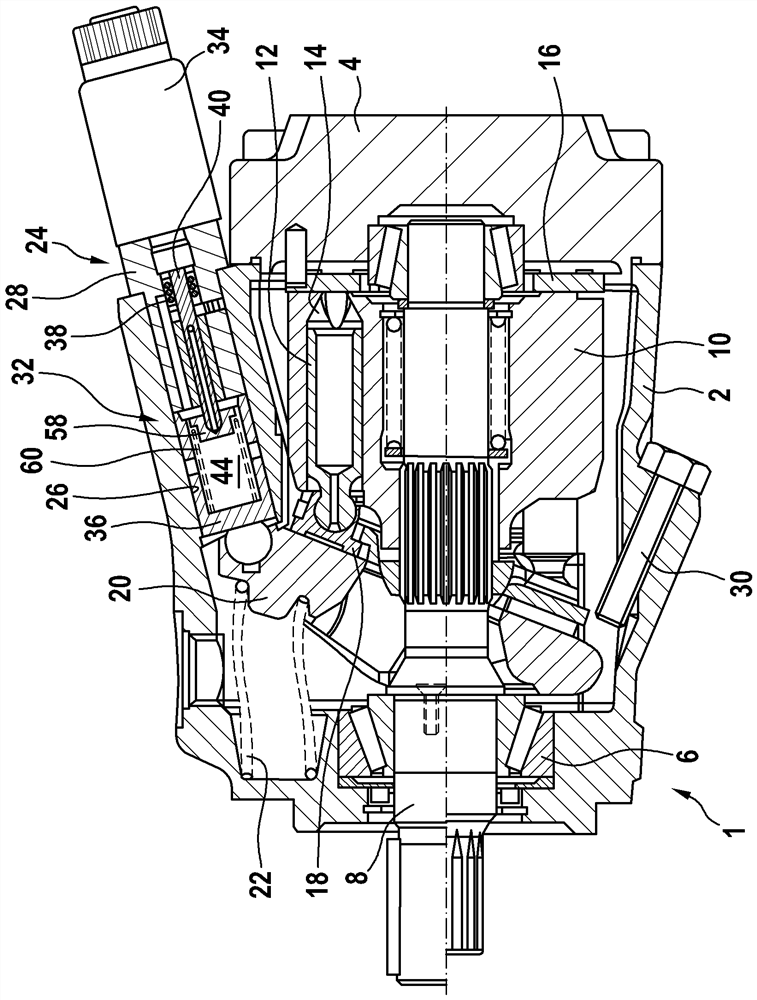

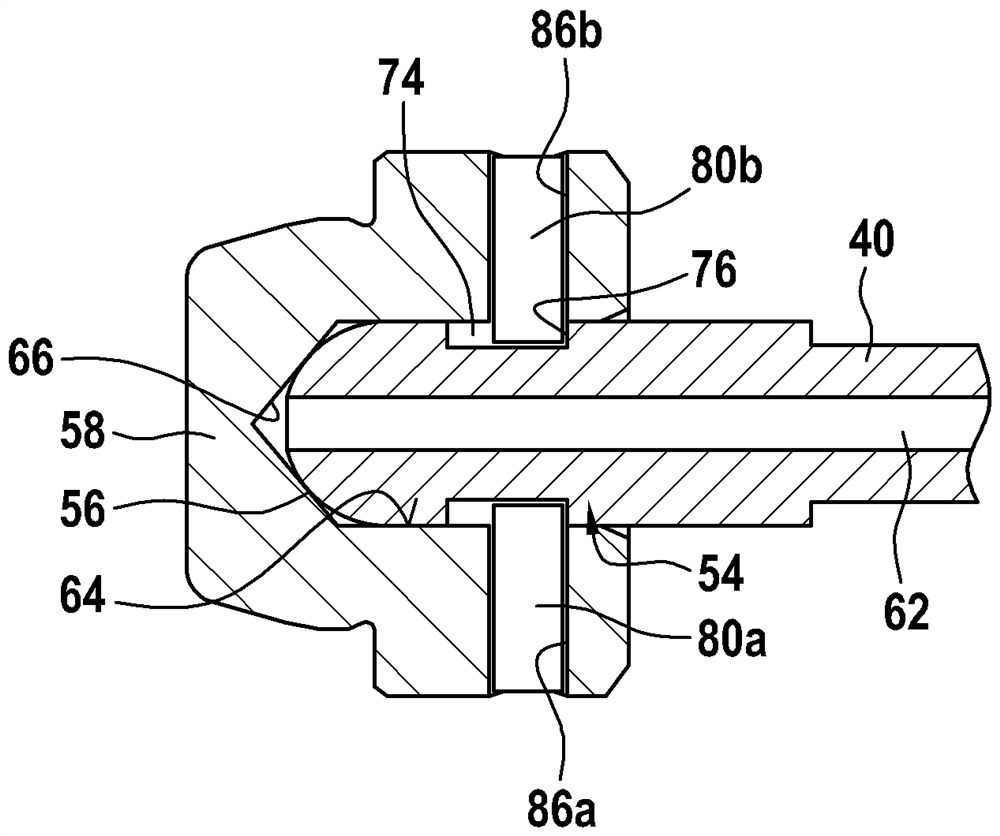

[0036] figure 1 A longitudinal section is shown of a hydraulic machine 1 embodied as an axial piston pump, which can be designed as a hydraulic pump or as a hydraulic motor. The hydraulic machine has a housing 2 and a housing cover 4 in which a shaft 8 is supported via a bearing seat 6 . The shaft is connected in a rotationally fixed manner to a cylinder 10 in which a plurality of pistons 12 is displaceably guided. Together with the cylinder 10 , these pistons each delimit a working chamber 14 , which can be connected to a high pressure or to a low pressure via a control disk 16 connected to the housing 2 , depending on the rotational position of the cylinder 10 . The bottom end section of the piston 12 facing away from the working chamber 14 is connected in each case to a slide 18 in the manner of a ball joint. These sliders 18 bear against the sliding surfaces of a swash plate 20 , also referred to as a cradle, which is rotatably supported in the housing 2 so that the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com