Disc brake for a utility vehicle

A technology for disc brakes and commercial vehicles, applied in the types of brakes, axial brakes, brake components, etc., can solve problems such as high production costs and consumption, and achieve cost savings, avoid rattling noise, and reduce assembly costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

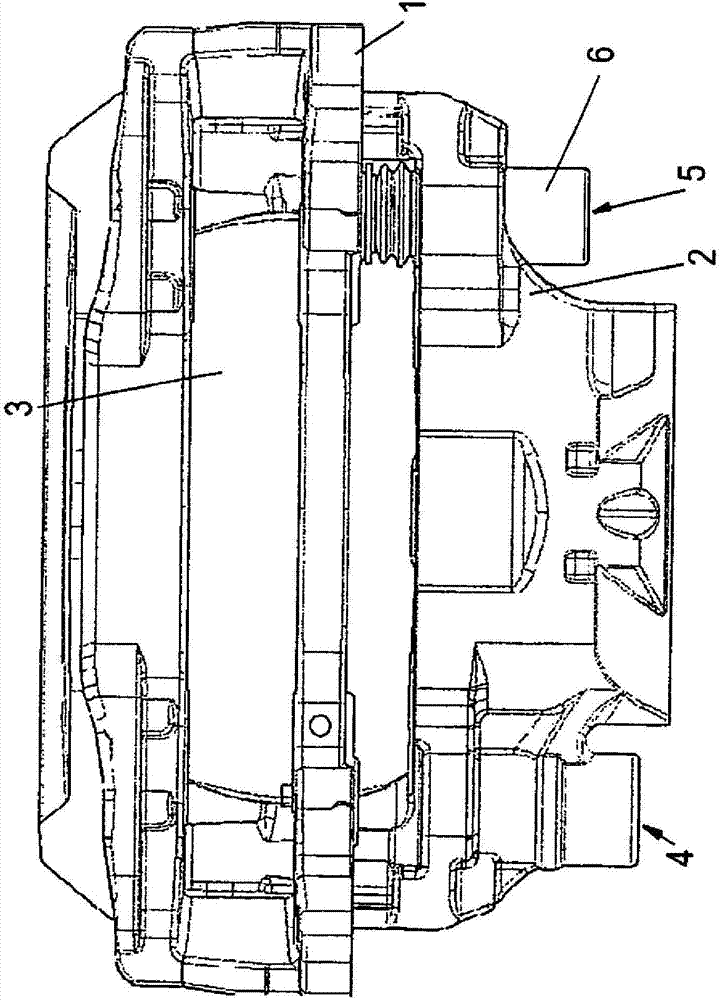

[0033] exist figure 1 shows a disc brake for a commercial vehicle, which has, in its basic construction, a brake caliper 2 which encloses a brake disc 3 which is fastened in a non-rotatable on the axis shown.

[0034] The brake caliper 2 is arranged axially displaceable relative to the brake disc 3 on a stationary brake carrier 1 of the commercial vehicle.

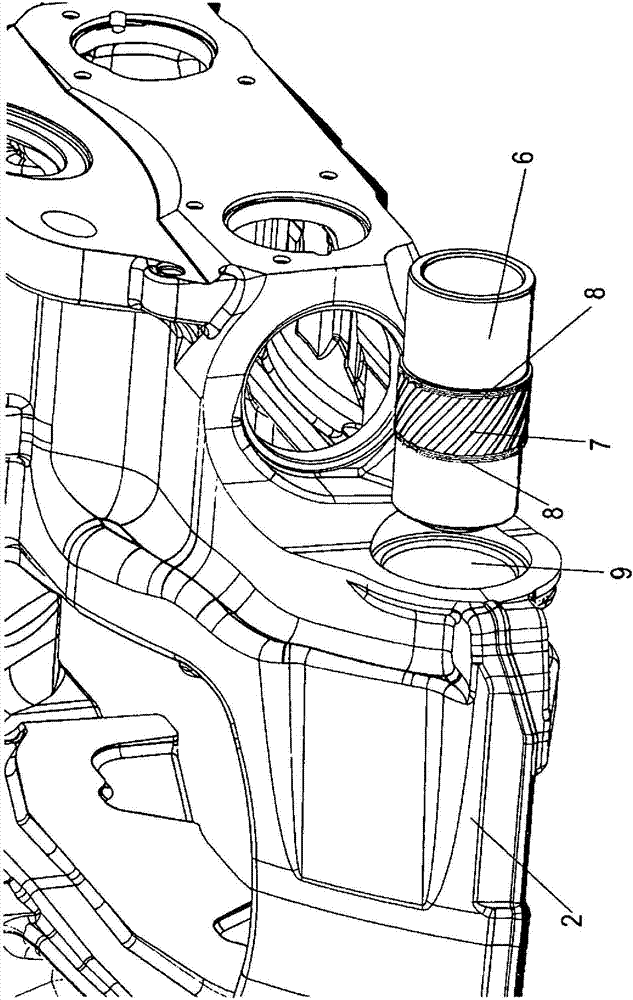

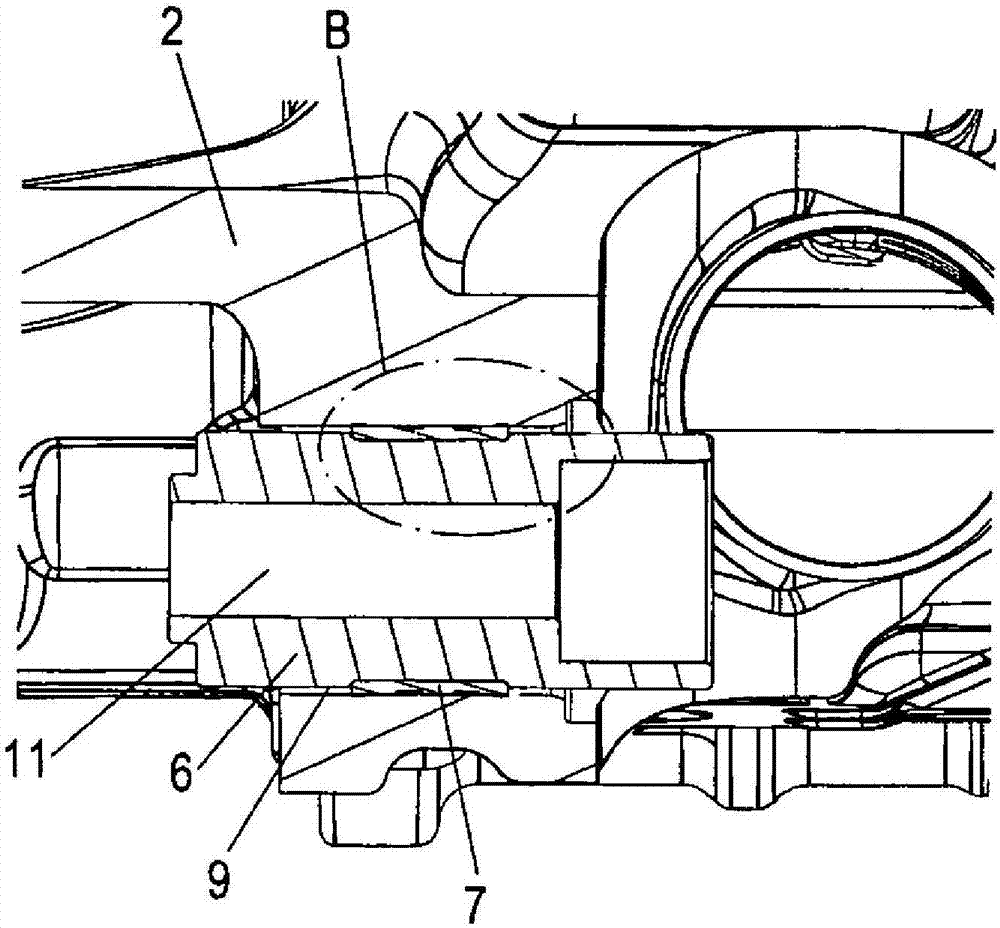

[0035] Two fastening elements are provided, each having a guide rod 6 connected to the brake carrier 1 and fastened to the brake carrier 1 by means of screws not shown. In this case, one fastening element is designed as a fixed bearing 4 and the other fastening element is designed as a floating bearing 5 .

[0036] For supporting the guide rod 6 , that is to say for guiding the brake caliper 2 in the axial direction, the non-locating bearing 5 has a sliding bush 7 made of plastic, preferably elastomer, which according to the invention is held in a displacement-proof manner on the guide rod 6, as available in figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com