Chemical oxygen production apparatus

An oxygen production device and chemical technology, applied in the direction of inorganic chemistry, chemical instruments and methods, oxygen/ozone/oxide/hydroxide, etc., can solve the problems of low oxygen production efficiency, inability to produce a large amount of oxygen, complex structure, etc. , to achieve the effect of easy promotion, convenient use and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

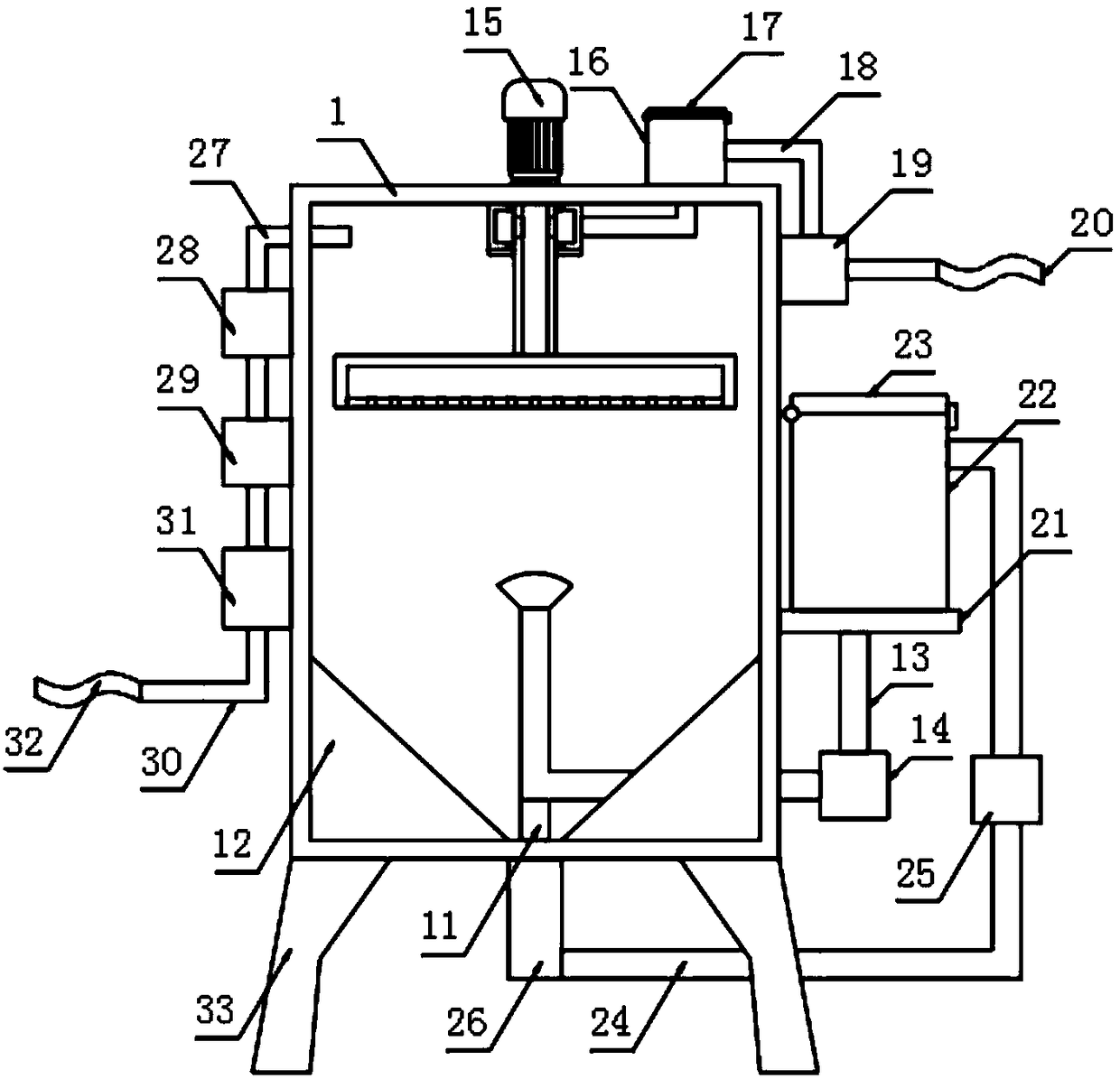

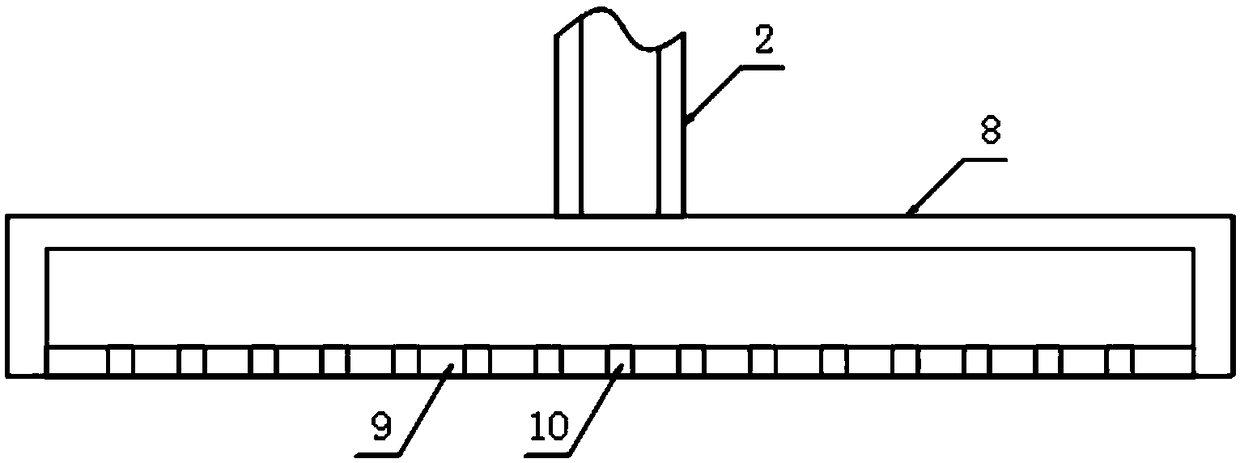

[0026] The present invention provides such as Figure 1-5 The shown chemical oxygen production device includes a reaction chamber 1, a hollow rotating rod 2 runs through the top of the reaction chamber 1, and a feed hole 3 runs through the side wall of the hollow rotating rod 2. The outer side of the rotating rod 2 is sleeved with a connecting chamber 4, and the side of the connecting chamber 4 is provided with a first feed pipe 7, and the bottom end of the hollow rotating rod 2 is fixed with a diverging chamber 8, and the bottom of the diverging chamber 8 is embedded A partition 9 is sleeved, and a through hole 10 is formed on the partition 9. A placement seat 11 is fixed at the bottom of the inner cavity of the reaction chamber 1, and a liquid inlet pipe 13 is fixed at the top of the placement seat 11. The top of the liquid inlet pipe 13 is fixed with a shower head 38, the liquid inlet pipe 13 is provided with a first booster pump 14, the top of the reaction chamber 1 is fix...

Embodiment 2

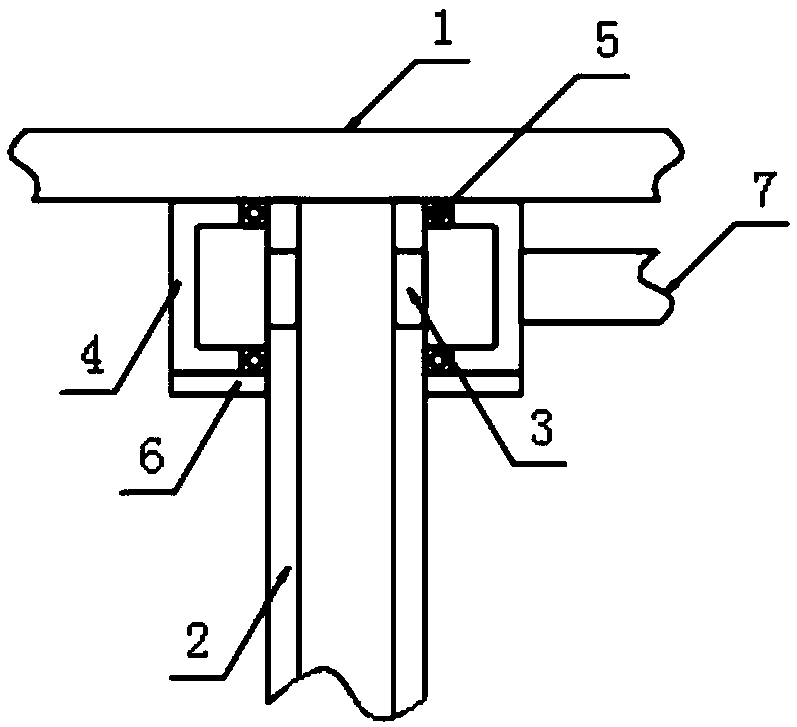

[0029] Further, in the above-mentioned embodiment 1, the connecting chamber 4 is fixedly arranged on the top of the inner cavity of the reaction chamber 1, and a bearing 5 is provided between the hollow rotating rod 2 and the connecting chamber 4, and the inner side of the bearing 5 is connected with the hollow rotating rod. The rod 2 is fixedly connected, the outer side of the bearing 5 is fixedly connected with the connection cavity 4 , and the bottom of the connection cavity 4 is fixedly provided with a sealing plate 6 .

[0030] Further, in the above-mentioned embodiment 1, the bottom of the inner cavity of the reaction chamber 1 is fixed with a flow guide block 12, the flow guide block 12 is arranged on the outside of the placement seat 11, and the top of the flow guide block 12 is provided with a flow guide block. The section of the diversion groove is set as an inverted isosceles trapezoid, so that the unreacted hydrogen peroxide slides down along the diversion block 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com