Sludge treatment device

A technology of sludge treatment and support plate, which is applied in the direction of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of short service life of the machine and timing treatment of the sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

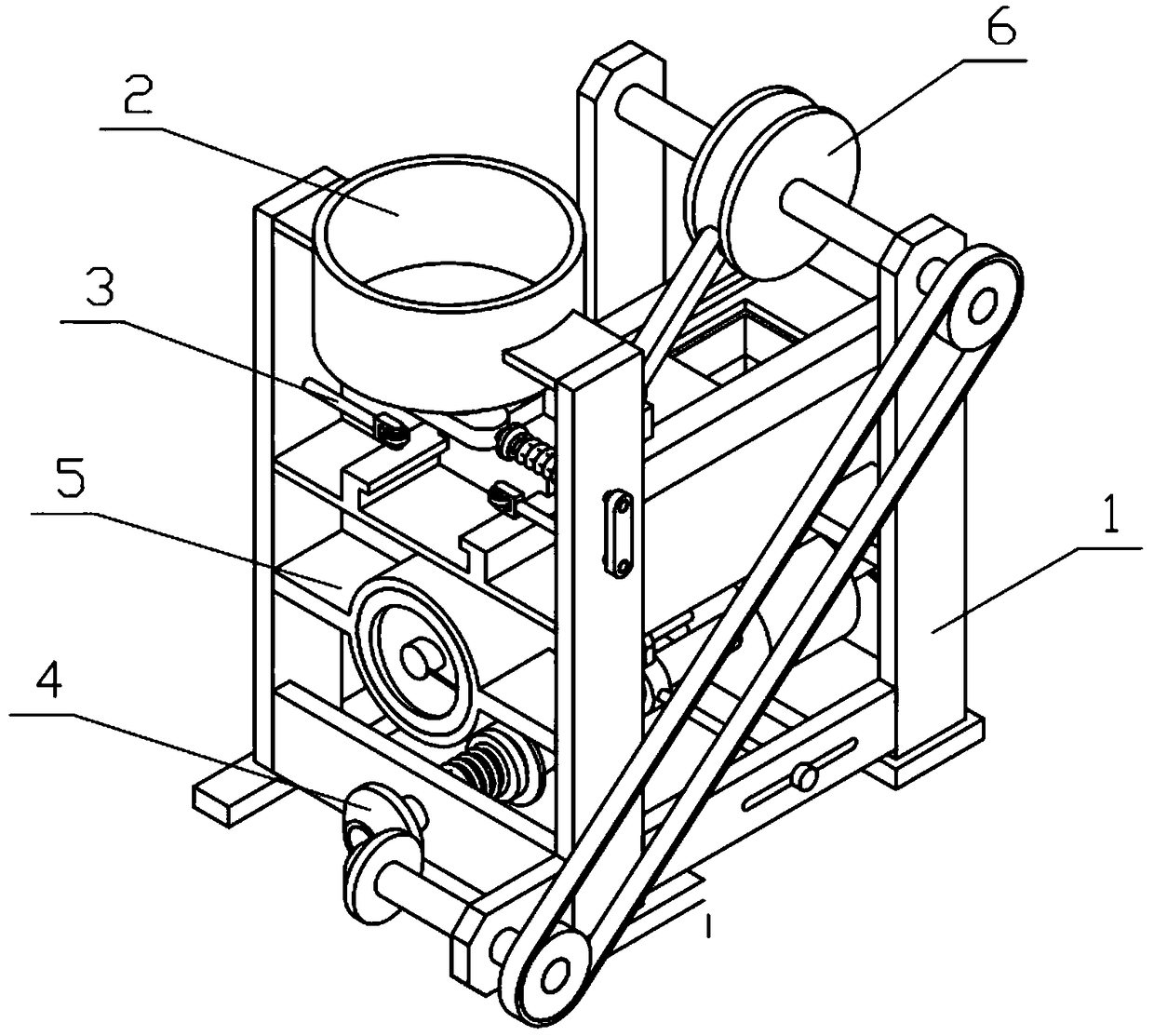

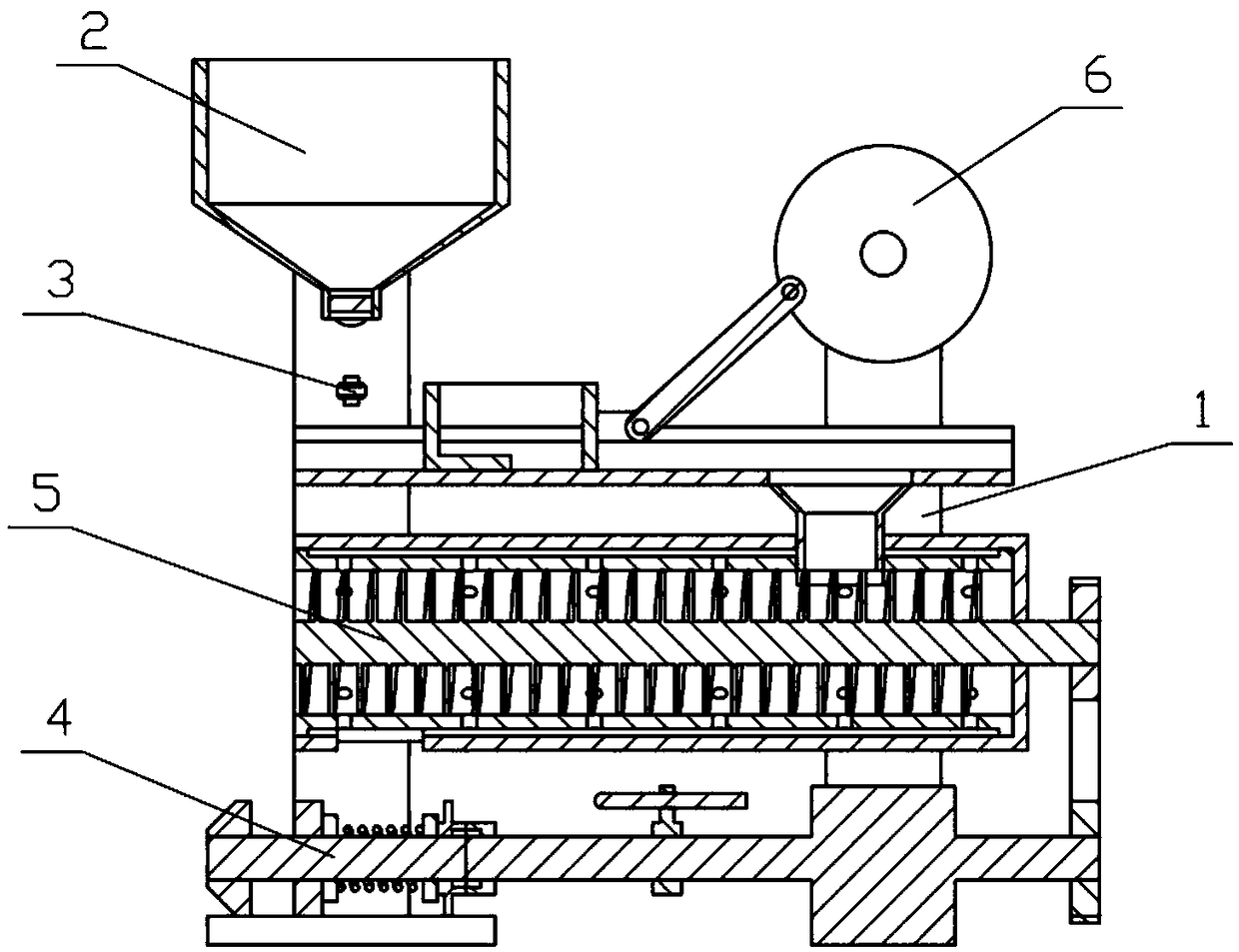

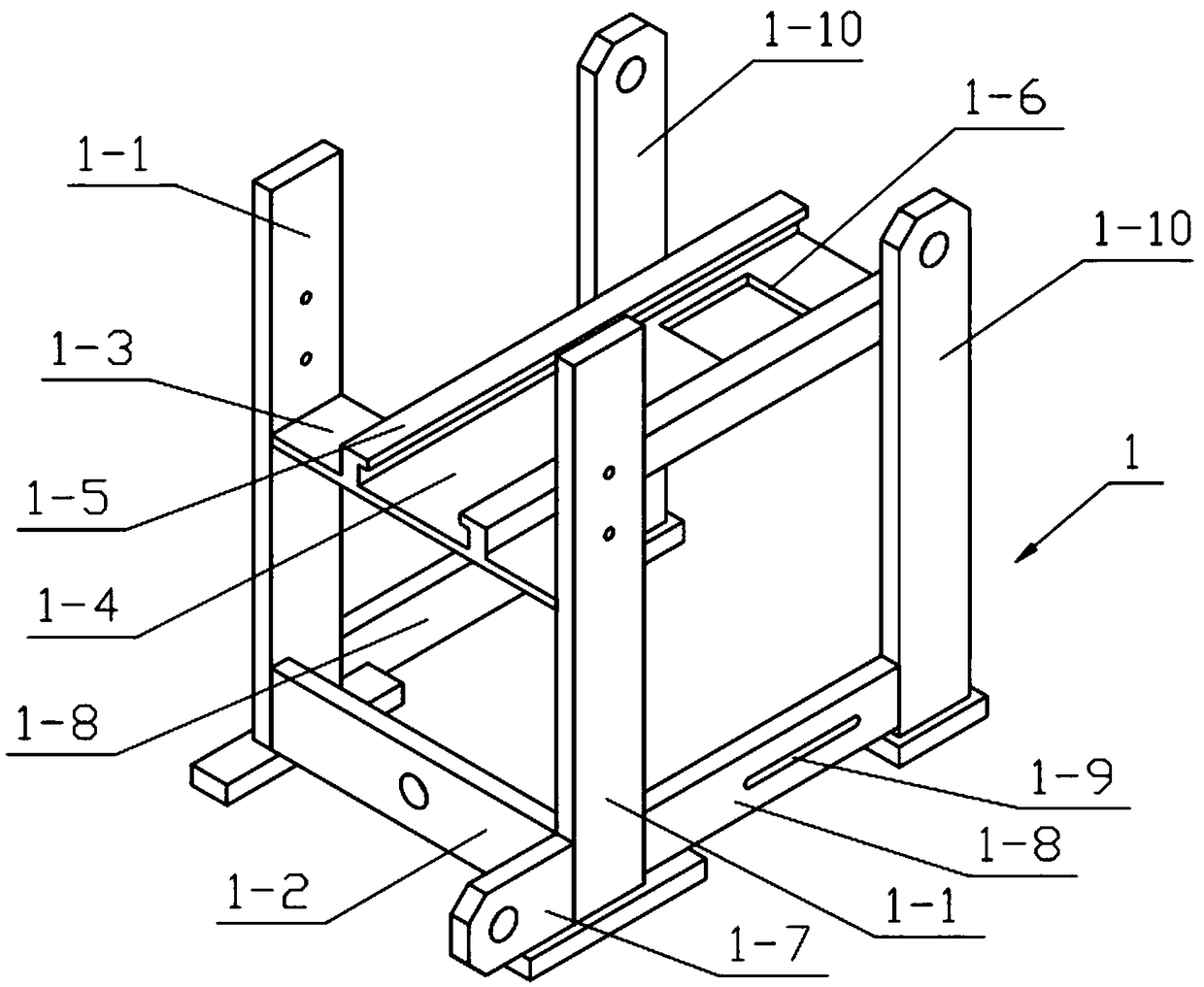

[0031] Combine below Figure 1-11 Describe this embodiment, a sludge treatment device, including a complete machine support 1, a discharge support 2, a closing mechanism 3, a power mechanism 4, a dehydration mechanism 5 and a feeding mechanism 6, which can pass through the threaded cylinder 4 set on the power mechanism 4 -4. The sliding column 4-5 and the threaded column 4-6 realize the timing transmission of the motor 4-1 to the friction wheel II 4-8, and control the working time of the feeding mechanism 6 by controlling the rotation time of the friction wheel II 4-8 to realize timing work , the machine can stop working automatically in the absence of manpower; the diameter of the dehydration pulley 5-6 is greater than the diameter of the power pulley 4-2 so that the power transmitted on the motor 4-1 can be applied to the dehydration mechanism 5 to work, dehydration The mechanism 5 can separate the sludge and water, and the reciprocating motion of the feeding mechanism 6 pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com