Method for Preventing Wax Blockage in Pipeline of Fully Enclosed Automatic Dehydrator and Its Anti-Clogging Wax Heating Control System

A fully enclosed, control system technology, applied in the anti-blocking wax heating control system and the field of anti-blocking wax, can solve the problems of difficult next work, easy blockage of paraffin into the wax pipe and the wax discharge pipe, etc., to prevent wax blockage. , Increase thoroughness and reliable durability, and ensure the effect of smooth pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

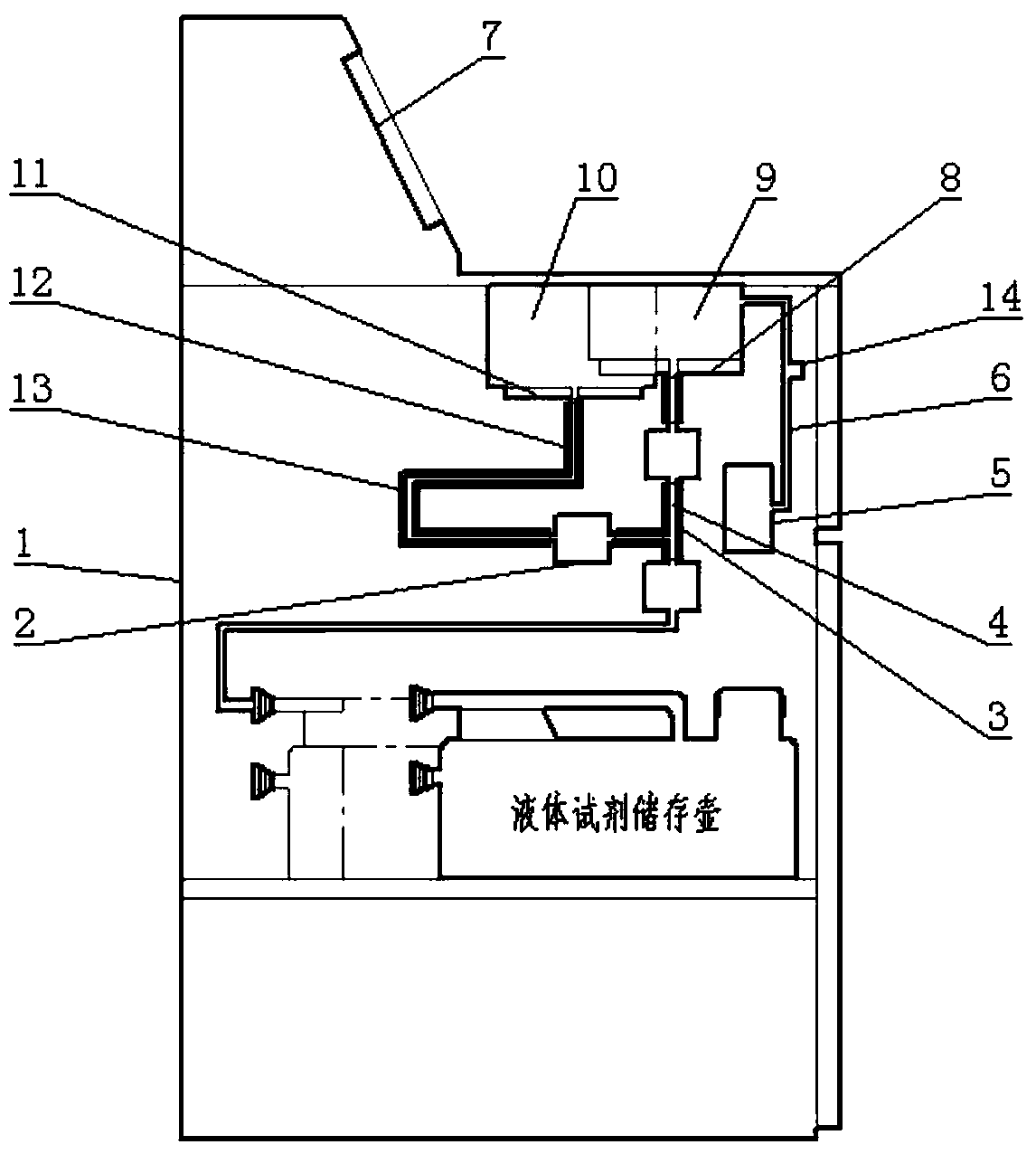

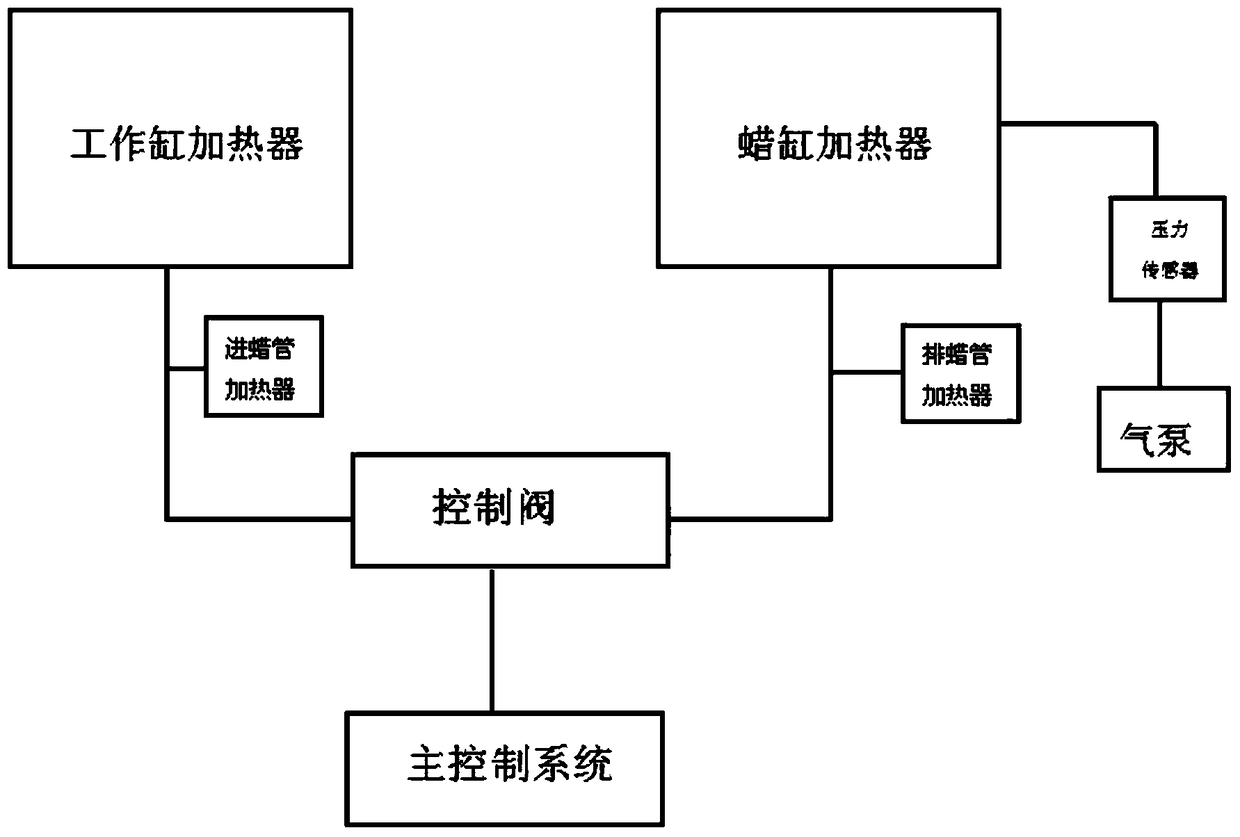

[0026] like figure 1 , figure 2 As shown, the method for preventing wax plugging in the pipeline of a fully enclosed automatic dehydrator (or automatic biological tissue dehydrator) comprises the following steps:

[0027] 1) Prepare the anti-blocking wax heating control system (as described below);

[0028] 2) First, heat the wax tank heater 11, the wax feeding pipe heater 13, the wax discharge pipe heater 3 and the working cylinder heater 8 to 65-75°C and keep the temperature constant; the state of wax feeding: through the air pump 5 and the air pipe 6, Add negative pressure to the working cylinder 9 and open the control valve 2. Under the action of pressure (adding negative pressure to the working cylinder and pumping air), the paraffin enters the working cylinder through the wax cylinder, wax inlet pipe, control valve and wax discharge pipe in turn. Cylinder, run according to the preset program; Wax removal state: After the specimen is processed in the working cylinder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com